Method for producing dry granules of ceramic raw material powder

A technology of ceramic raw materials and production methods, which is applied in the field of dry granulation of ceramic raw material powder products, can solve problems such as constraints, stable improvement of ceramic quality, high power consumption, etc., to save energy consumption, reduce production costs, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

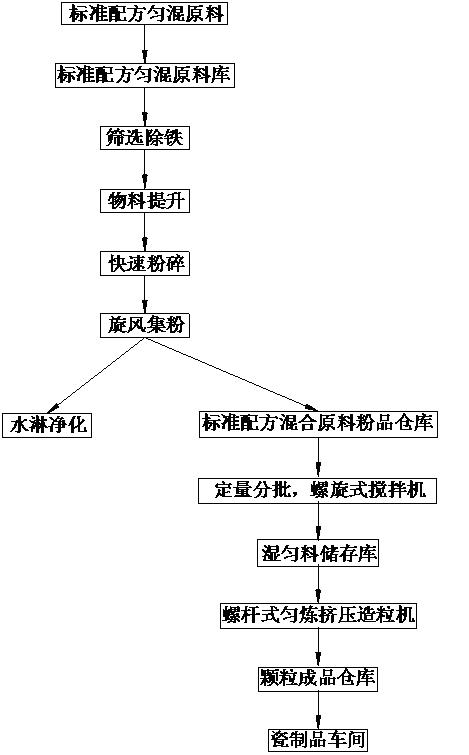

[0028] The dry granulation production method of ceramic raw material powder product of the present invention is characterized in that, carries out according to the following steps:

[0029] (1) Select the standard formula raw material dry powder product produced by the rapid processing method of ceramic powder raw material (patent number: 200610004085.6), and divide it into batches according to the quantity;

[0030] (2) Put batches of quantitative mixed raw material dry powder into the mixer, and stir to make it evenly mixed;

[0031] (3) According to the dry humidity of the above-mentioned mixture, spray an appropriate amount of water mist into the mixture in the mixer, and then stir evenly, so that the mineral powder particles are fully dispersed and the hum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com