New method for extracting gallium from Bayer mother liquor through chelating resin

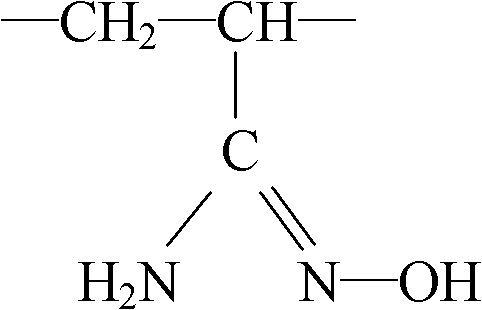

A technology of chelating resin and Bayer mother liquor, which is applied in the field of gallium extraction, to achieve the effects of cost saving, high gallium content and good gallium recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

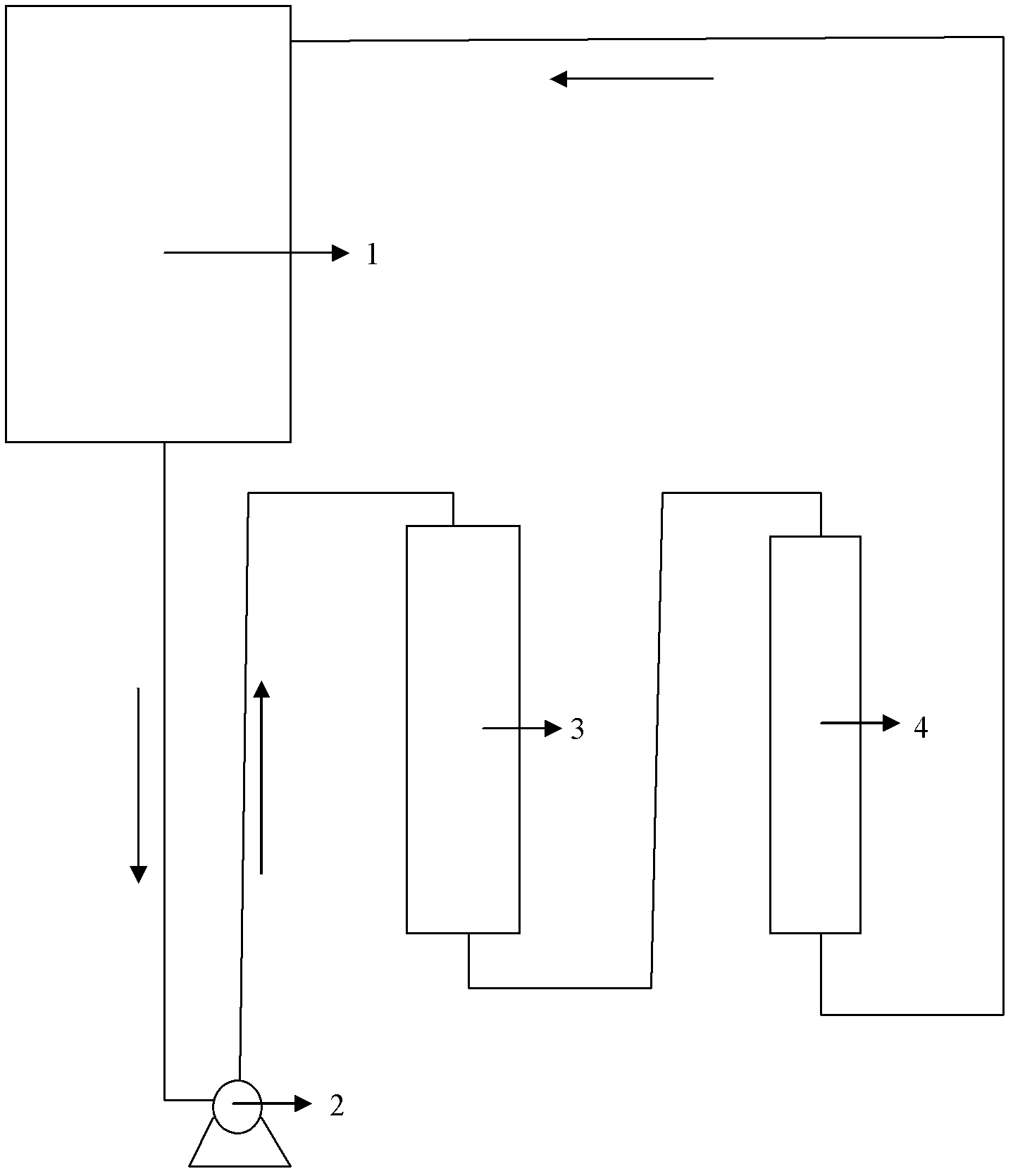

Method used

Image

Examples

Embodiment 1

[0031] Get 500ml of LSC-600 resin and pack it into an exchange column as a gallium extraction resin column. The Bayer mother liquor with a gallium concentration of 246 mg / L flows through the gallium extraction resin column at a flow rate of 4L / h until the resin reaches adsorption saturation, then wash with water until the resin The pH of the effluent from the column was 9.2, and the gallium adsorption capacity of the saturated resin was measured to be 4 g / L. Put 500ml of 001×7 resin in the exchange column as a gallium-rich resin column, and add 2.5L of citric acid solution of pH 1.2 into a 3L glass beaker as a buffer tank. Connect the saturated gallium extraction resin column to the gallium enrichment resin column and buffer tank in series, use a pump to control the citric acid solution to circulate at 15°C at a flow rate of 1.5L / h, and use a 3N citric acid solution to adjust the buffer The pH of the acid solution in the tank so that it remains around pH 1.2. When the gallium...

Embodiment 2-7

[0036] Get 500ml of LSC-600 resin and pack it into the exchange column as the gallium extraction resin column. The Bayer mother liquor with a gallium concentration of 259mg / L flows through the gallium extraction resin column at a flow rate of 3L / h until the resin reaches adsorption saturation. The pH of the effluent was 9.0, and the gallium adsorption capacity of the saturated resin was measured to be 4 g / L. Put 500ml of D001 resin in the exchange column as a gallium-rich resin column, and add 2.5L of phosphoric acid solution with a pH of 1.0 into a 3L glass beaker as a buffer tank. Connect the saturated gallium extraction resin column to the gallium enrichment resin column and the buffer tank in series, and use a pump to control the flow rate of the phosphoric acid solution at 1.0L / h, so that it is at 0°C, 5°C, 10°C, 15°C, and 20°C respectively. ℃, 35 ℃ cycle operation. Use a phosphoric acid solution with a concentration of 4N to adjust the pH value of the solution in the bu...

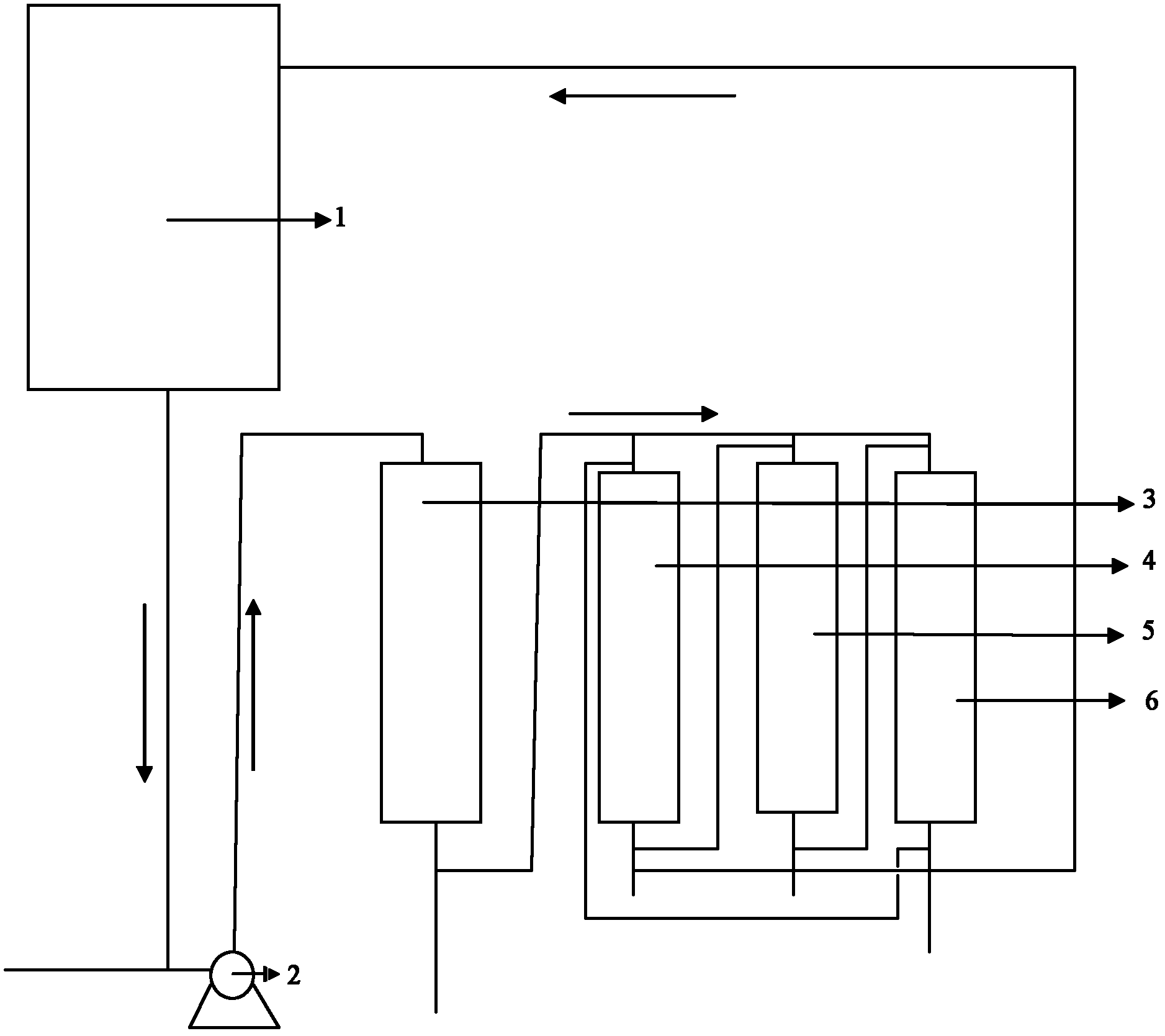

Embodiment 8-13

[0040] Take 3L of LSC-600 resin and put it into the exchange column as the gallium extraction resin column. The Bayer mother liquor with a gallium concentration of 240mg / L flows through the gallium extraction resin column at a flow rate of 10L / h until the resin reaches adsorption saturation. The pH of the effluent was 9.0, and the gallium adsorption capacity of the saturated resin was measured to be 4g / L, which was evenly distributed in 6 exchange columns. 500ml of D001 resin was loaded into the other 6 exchange columns as gallium-rich resin columns, and 2.5L of hydrochloric acid solution with pH values of 0, 0.1, 0.5, 1.5, 2.5, and 3 were added to 6 3L glass beakers as Buffer tank. The saturated gallium extraction resin column was connected in series with the gallium enrichment resin column and the buffer tank, and the acid solution was controlled by a pump at a flow rate of 1.0 L / h to make it circulate at 20°C. Use a hydrochloric acid solution with a concentration of 3.5N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com