Folding fastener

A technology of fasteners and fasteners, applied in the direction of connecting members, rod connections, mechanical equipment, etc., can solve the problems of small adjustment range of locking caliber, high processing accuracy requirements, and increase processing costs, so as to achieve the bonding area. Small size, large fitting area, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

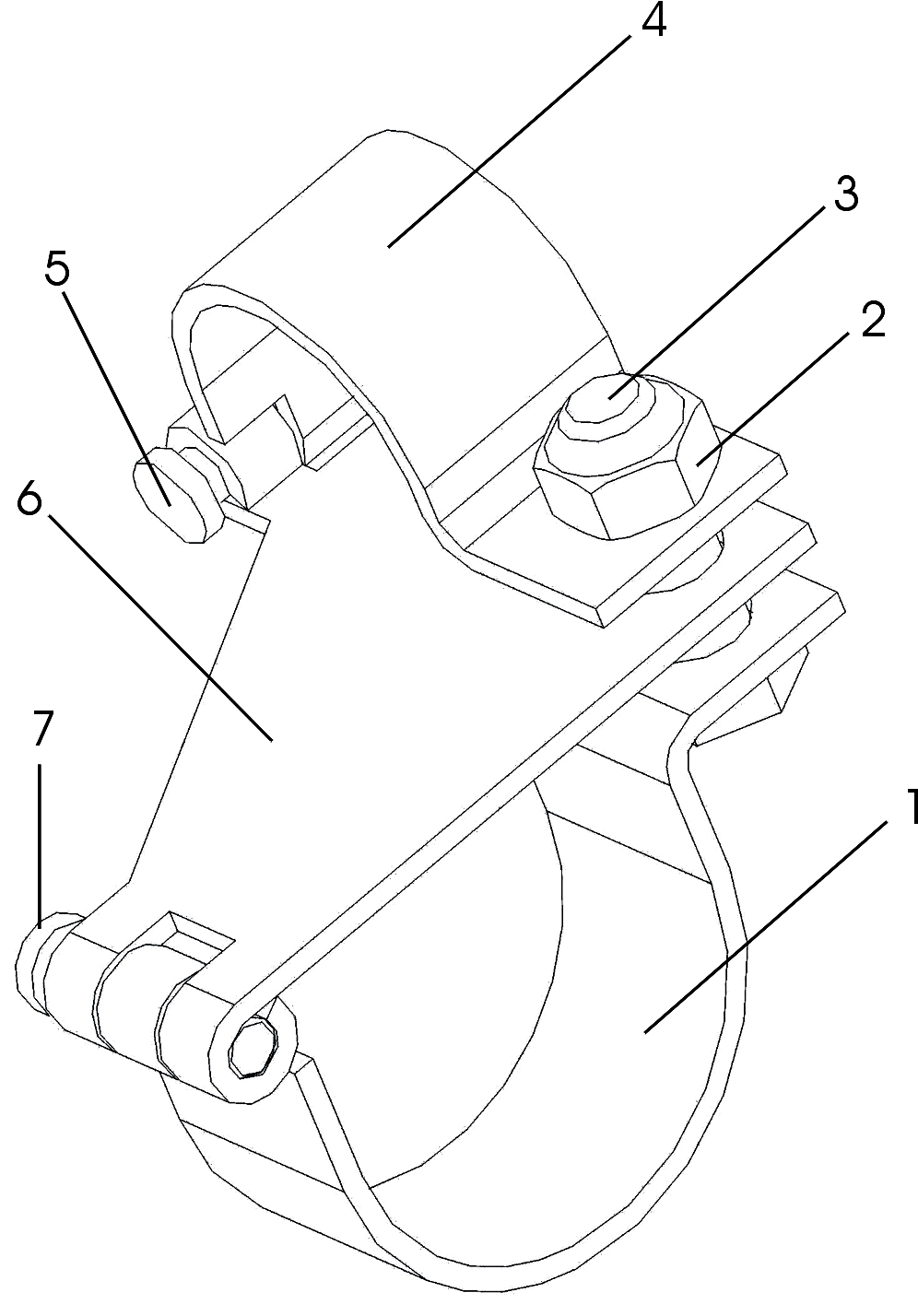

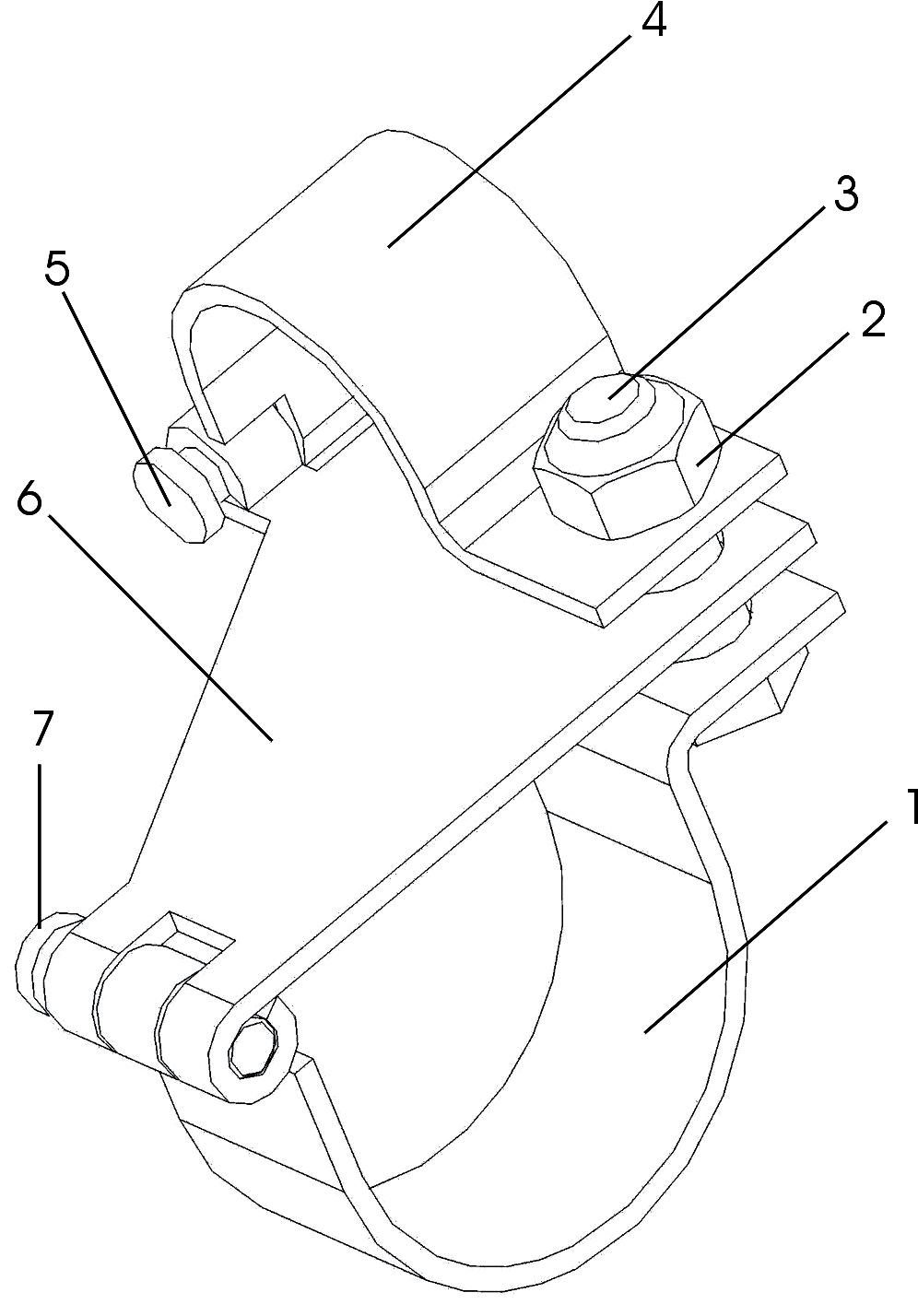

[0007] Now refer to the attached figure 1 In combination with the embodiments, the description is as follows: The folding fastener of the present invention includes a fastener A1, a nut 2, a bolt 3, a fastener B4, a hinge pin B5, a center plate 6 and a hinge pin A7. The center plate 6 is the centering piece of the folding fastener of the present invention. It has a triangular plate-shaped structure as a whole. The triangular plate-shaped structure mentioned here is not intended to be such a restriction. It is also possible to adopt other geometric forms that allow strength, but In terms of meeting the requirements of strength and saving raw materials, it is better to adopt a triangular plate structure. At one of the corners of the center plate 6, a roll hole is provided, which is connected to the fastener A1 through a hinge pin A7; at the other corner of the center plate 6, a roll hole is also provided, which is connected to the buckle through a hinge pin B5 The fitting B4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com