Conical double-layer heat sink device compatible with two media of liquid nitrogen and liquid helium and refrigeration method thereof

A conical, double-medium technology, applied in the conical double-layer heat sink device and its refrigeration field, can solve the problems of increasing the heat sink area, achieve the effect of increasing the heat sink area, facilitating the pipeline layout, and reducing heat radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

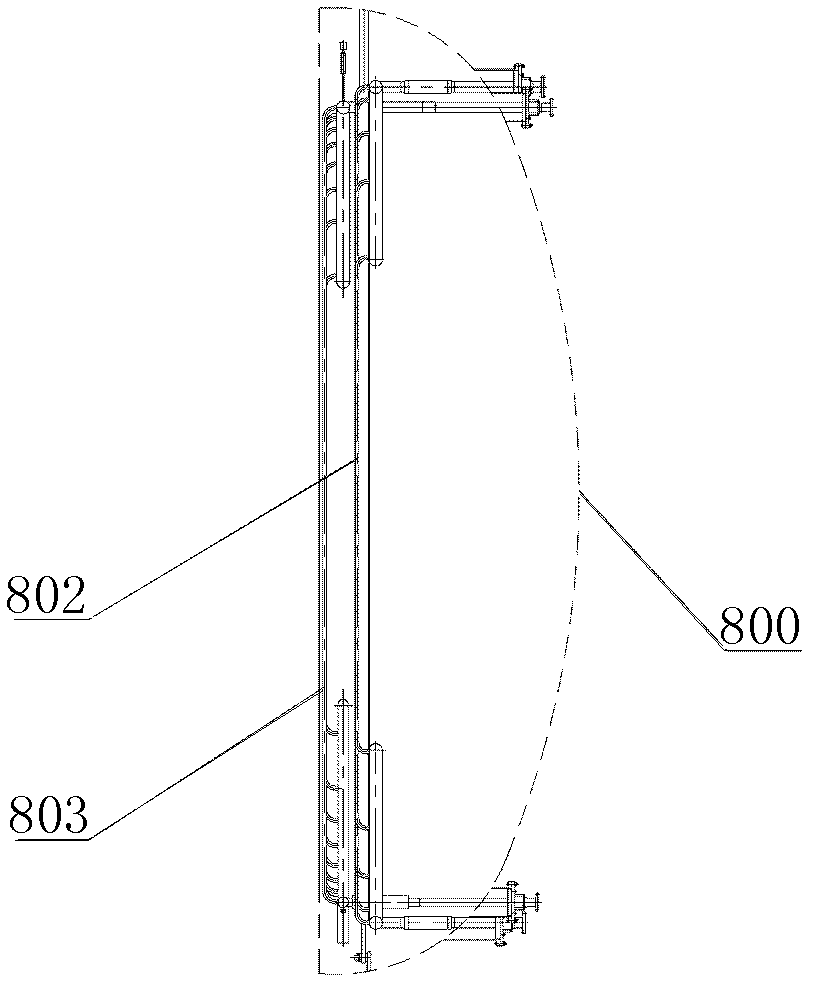

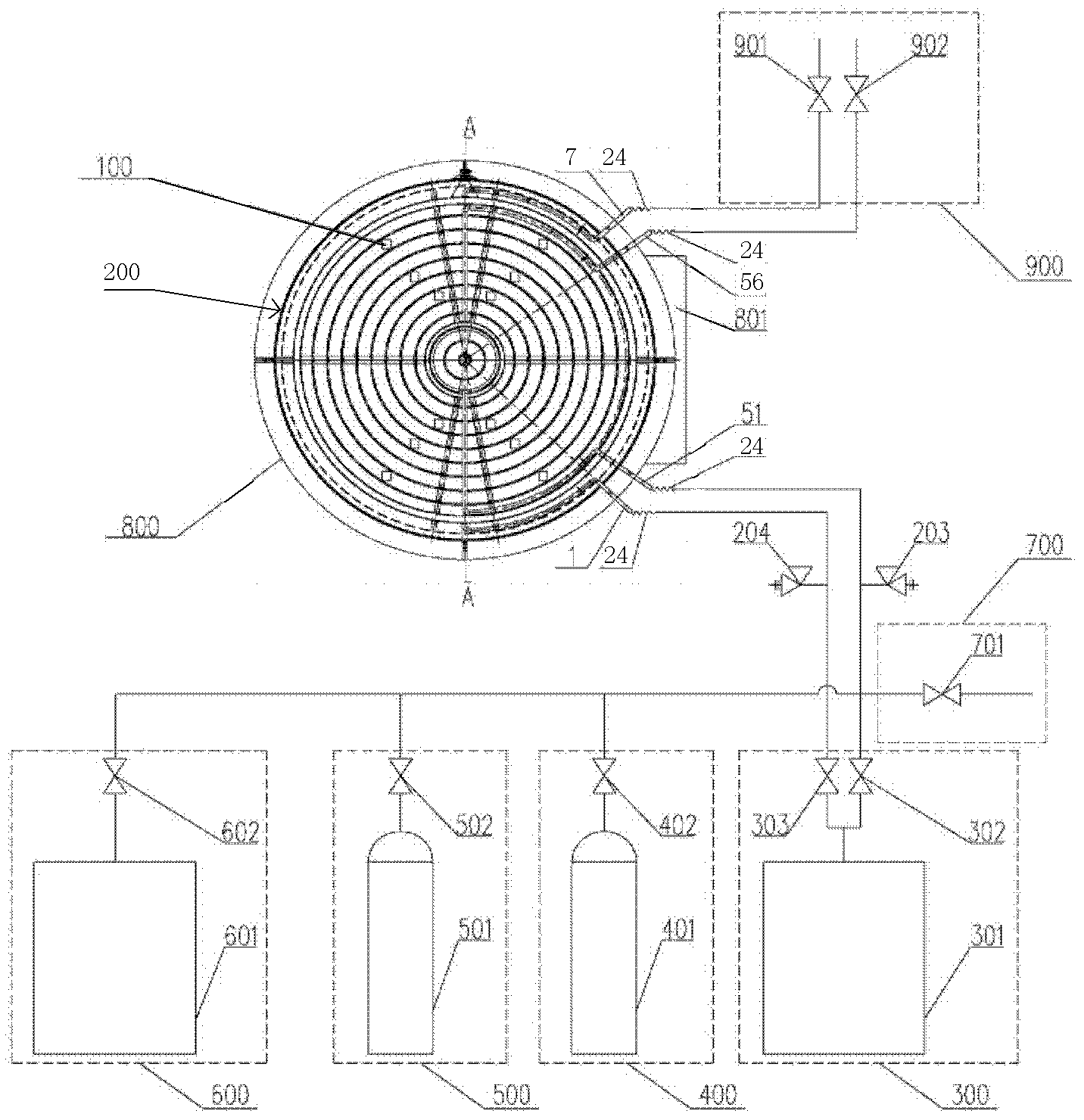

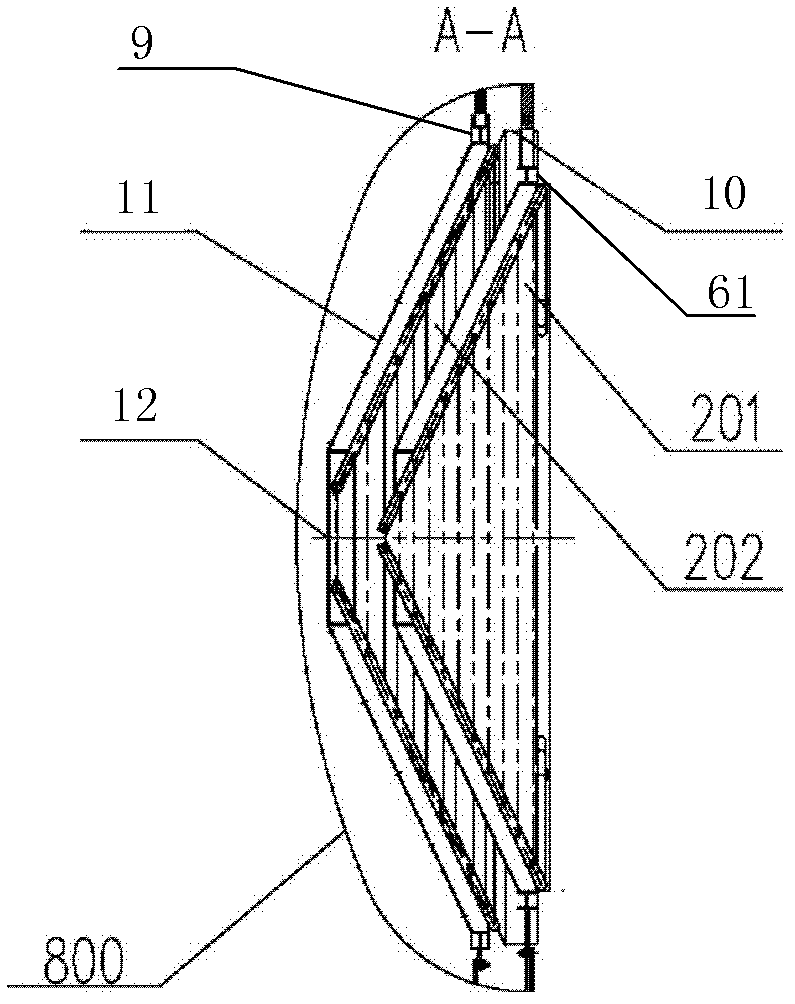

[0049] The conical double-layer heat sink device compatible with liquid nitrogen and liquid helium dual media provided by the invention, such as figure 2 with image 3 As shown, it includes a heat sink surface resistance temperature sensor 100, a conical heat sink body 200, a liquid nitrogen supply system 300, a gas nitrogen blow-off system 400, a gas helium blow-off system 500, a liquid helium supply system 600, and an auxiliary liquid drainage system 700 and fluid drainage system 900 .

[0050] The liquid nitrogen supply system 300 is composed of a liquid nitrogen storage tank 301 , a liquid nitrogen supply valve 302 for a liquid helium heat sink, and a liquid nitrogen supply valve 303 for a liquid nitrogen heat sink. The liquid nitrogen storage tank 301 is connected to the liquid helium heat sink liquid nitrogen supply valve 302 and the liquid n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com