Multipoint laser detection device for shearing strain of material

A multi-point laser and detection device technology, which is applied in the direction of measuring devices, analyzing materials, and using stable shear force to test the strength of materials, etc., can solve the problems that the detection results cannot be fully obtained, the test efficiency is affected, and the teaching effect is reduced. , to achieve the effect of intuitive and open test process, low equipment and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

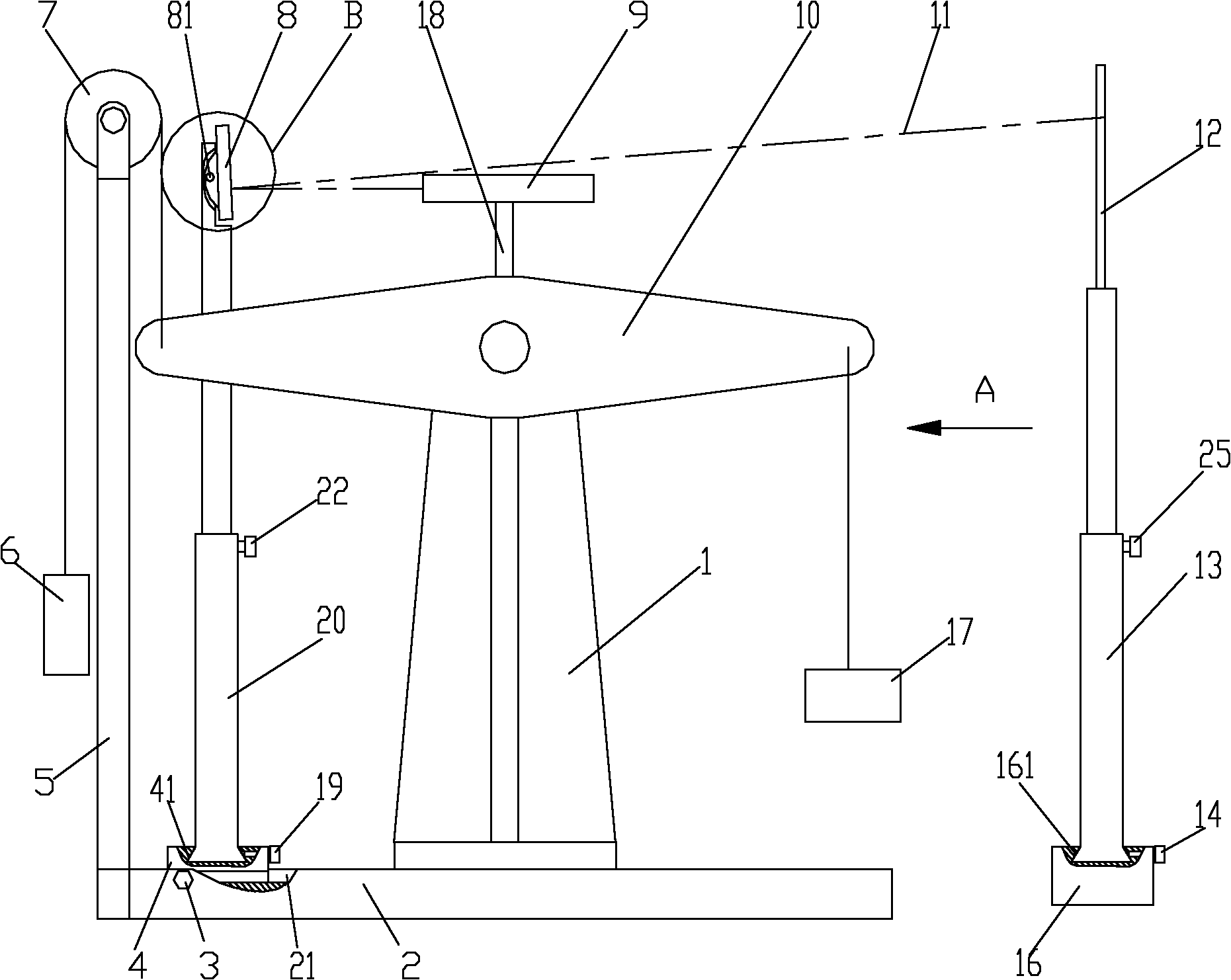

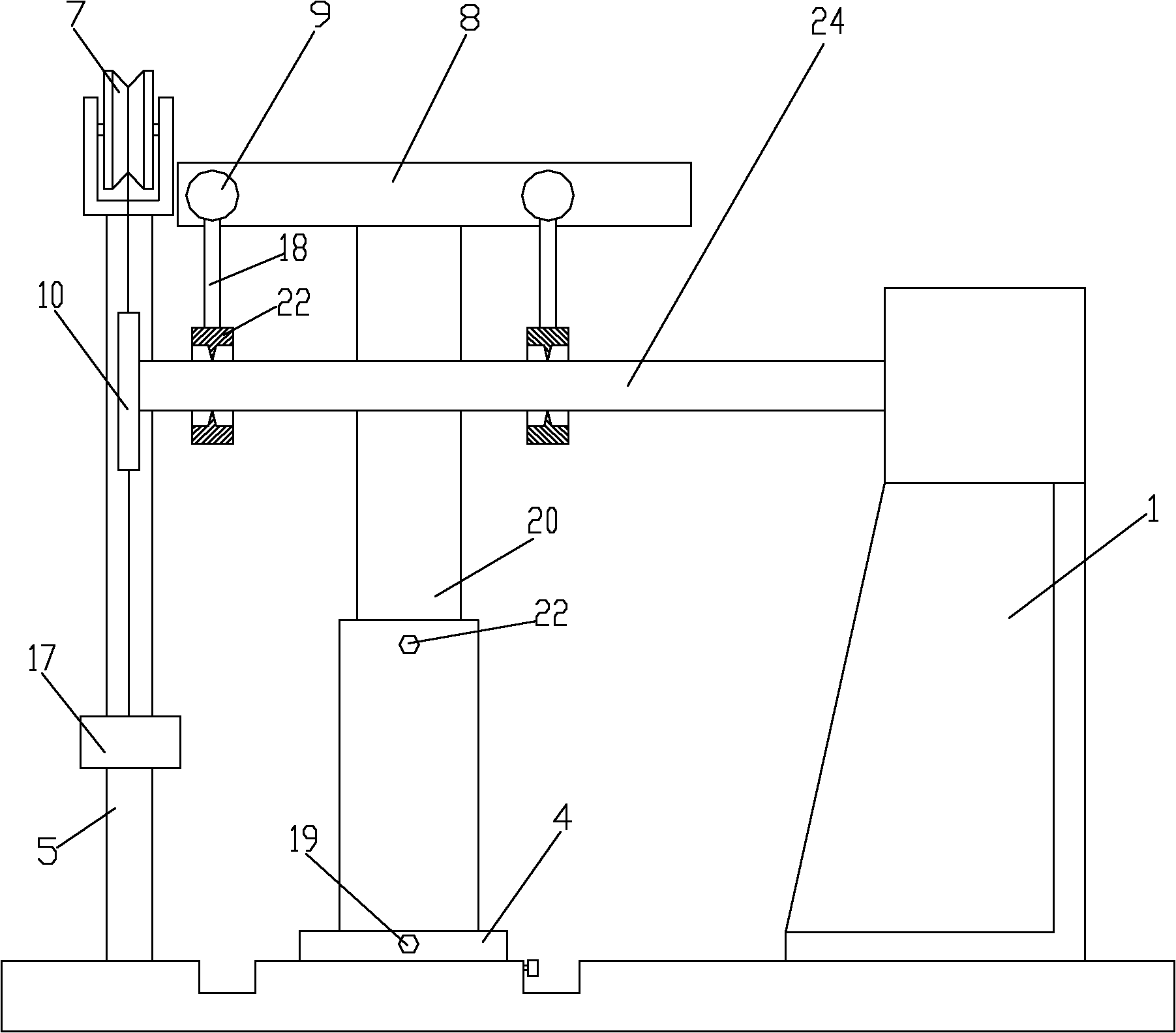

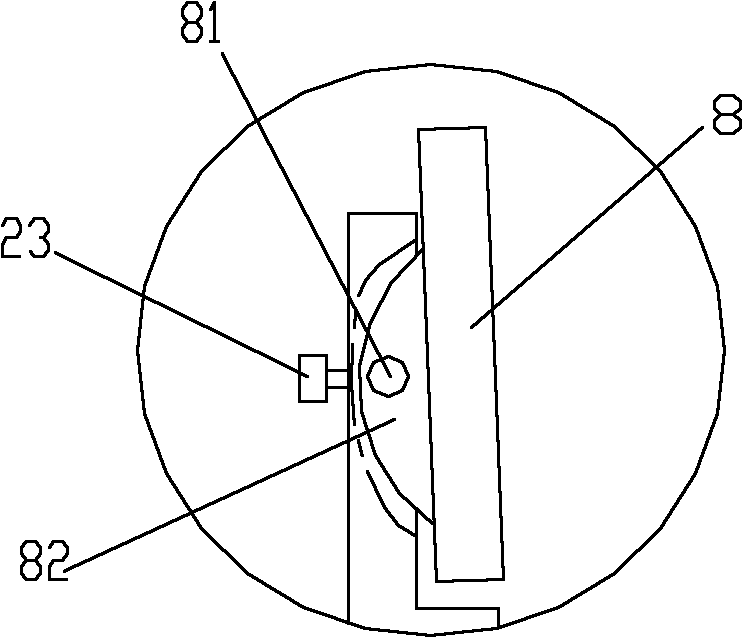

[0025] figure 1 It is a schematic diagram of the structure of the present invention, figure 2 for figure 1 View along direction A, image 3 for figure 1 The enlarged view at B of , as shown in the figure: the material shear strain multi-point laser detection device of this embodiment includes a specimen support assembly, a moment application assembly and a laser detection assembly;

[0026] The specimen support assembly includes a specimen support 1 for fixing and supporting the specimen horizontally; as shown in the figure, the fixing method can adopt any fixing method in the prior art, which can achieve the purpose of the invention; Purpose, generally fixed in the circumferential direction, such as clamp fixtures;

[0027] The laser detection assembly includes at least two lasers 9 distributed longitudinally along the test piece, two in this embodiment; the lasers 9 are fixedly arranged on the laser fixtures corresponding to them one by one, and the laser fixtures are f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com