Experimental apparatus and method for testing gas-sensitive temperature characteristic of carbon nanotube sensor

A technology of carbon nanotubes and temperature characteristics, applied in the direction of material resistance, etc., can solve the problems of inability to test the gas-sensing temperature characteristics of carbon nanotube sensors, uncontrollable gas flow rate to be detected, and low temperature control accuracy, and achieve flexible and convenient testing. The effect of fast detection and improved sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

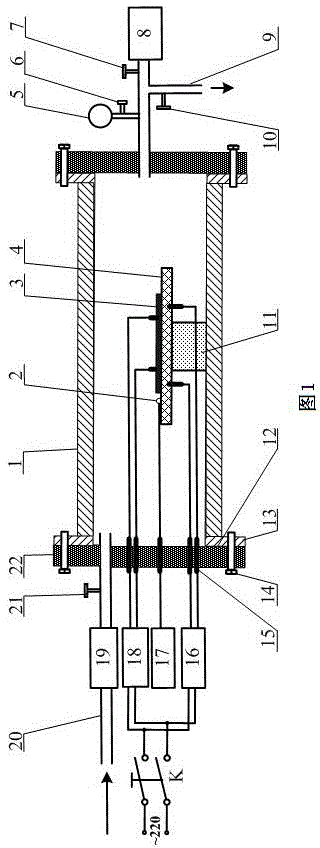

[0030] Such as figure 1 As shown, an experimental device for measuring the gas-sensing temperature characteristics of a carbon nanotube sensor mainly includes a quartz glass tube 1, a gas flow meter 19, a ceramic heating plate 4, a thermal resistance probe 2, an AC voltage regulator 16, and a digital display thermometer 17. Vacuum pump 8, impedance analyzer 18, etc. The feature is that the material of the quartz glass tube 1 is quartz glass, and the shape of the quartz glass tube 1 is cylindrical with a wall thickness of 4mm, an inner diameter of 35mm, and a length of 150mm. Quartz glass flanges 13 with an inner diameter of 35 mm, an outer diameter of 50 mm and a thickness of 4 mm are fixedly connected to both ends of the quartz glass tube 1 . The quartz glass flange 13 is fixedly connected to the stainless steel sealing piece 22 through the bolt 14 and the O-ring 12, so as to form a closed space in the quartz glass tube 1, so that the measured gas in the quartz glass tube 1 ...

Embodiment 2

[0032] An experimental device for measuring the gas-sensitive temperature characteristics of a carbon nanotube sensor, the same as in Example 1, wherein: the wall thickness of the quartz glass tube 1 is 5 mm, the inner diameter is 40 mm, and the length is 170 mm; the inner diameter of the quartz glass flange 13 is 40 mm, and the outer diameter is 40 mm. The diameter is 60mm, the thickness is 5mm; the length of the quartz glass block 11 is 13mm, the width is 13mm, and the height is 23mm; the length of the ceramic heater 4 is 33mm, the width is 33mm, the thickness is 2mm, and the power is 300W; The diameters of the first through hole and the second through hole on the stainless steel sealing sheet 22 at the end are both 5mm.

Embodiment 3

[0034] An experimental device for measuring the gas-sensitive temperature characteristics of a carbon nanotube sensor, the same as in embodiment 1, wherein: the wall thickness of the quartz glass tube 1 is 6 mm, the inner diameter is 45 mm, and the length is 200 mm; the inner diameter of the quartz glass flange 13 is 45 mm, and the outer diameter is 45 mm. The diameter is 65mm, the thickness is 6mm; the length of the quartz glass block 11 is 15mm, the width is 15mm, and the height is 25mm; the length of the ceramic heater 4 is 35mm, the width is 35mm, the thickness is 3mm, and the power is 350W; The diameters of the first through hole and the second through hole on the stainless steel sealing sheet 22 at the end are both 6mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com