Secondary lithium ion battery and electric capacity improving method thereof

A technology for lithium-ion batteries and battery casings, applied in secondary batteries, battery pack components, non-aqueous electrolyte storage batteries, etc., can solve the problems of increased cost, fast capacity decay, and low liquid injection volume, so as to ensure that the product is qualified efficiency, capacity maximization, and good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

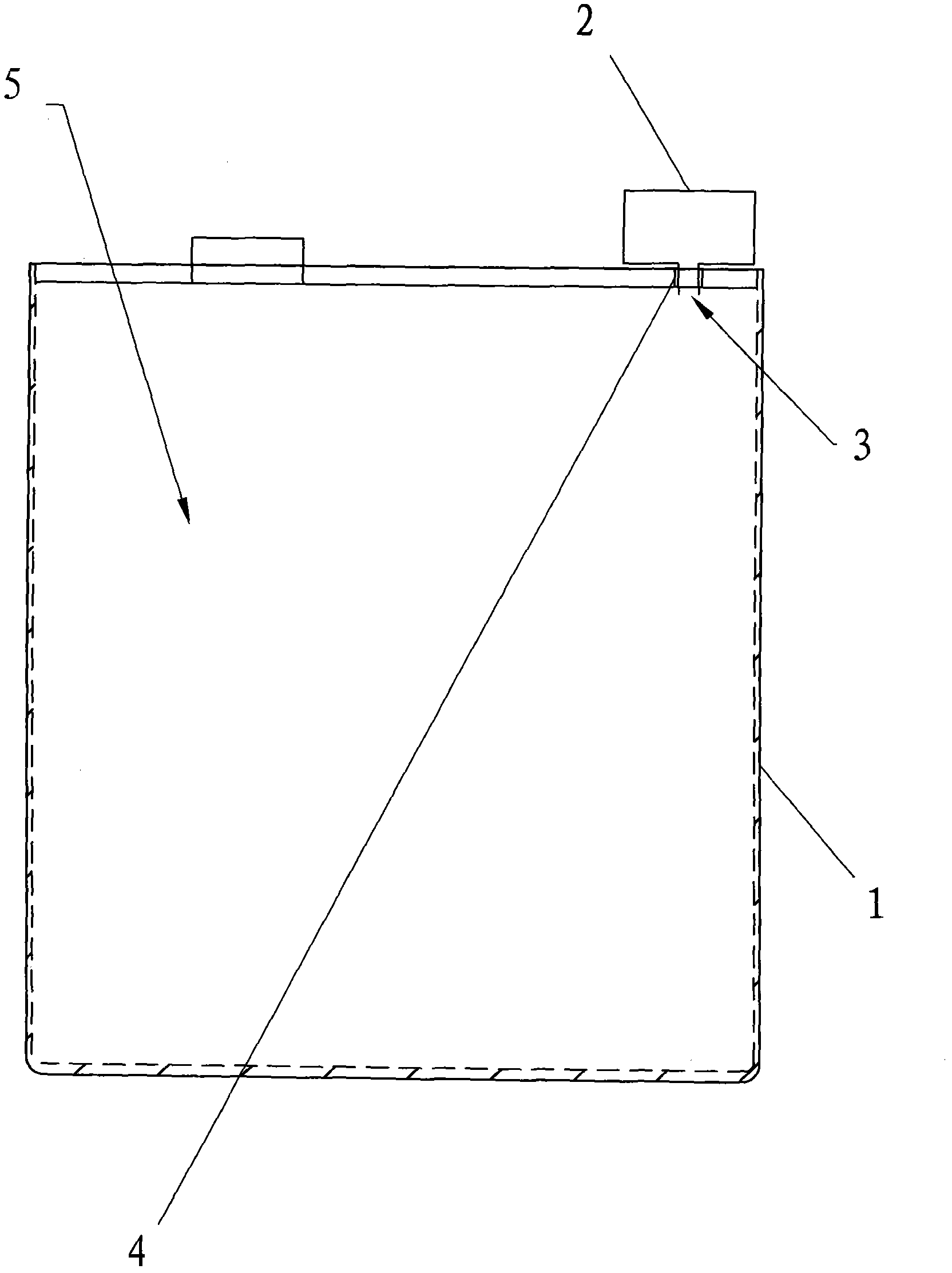

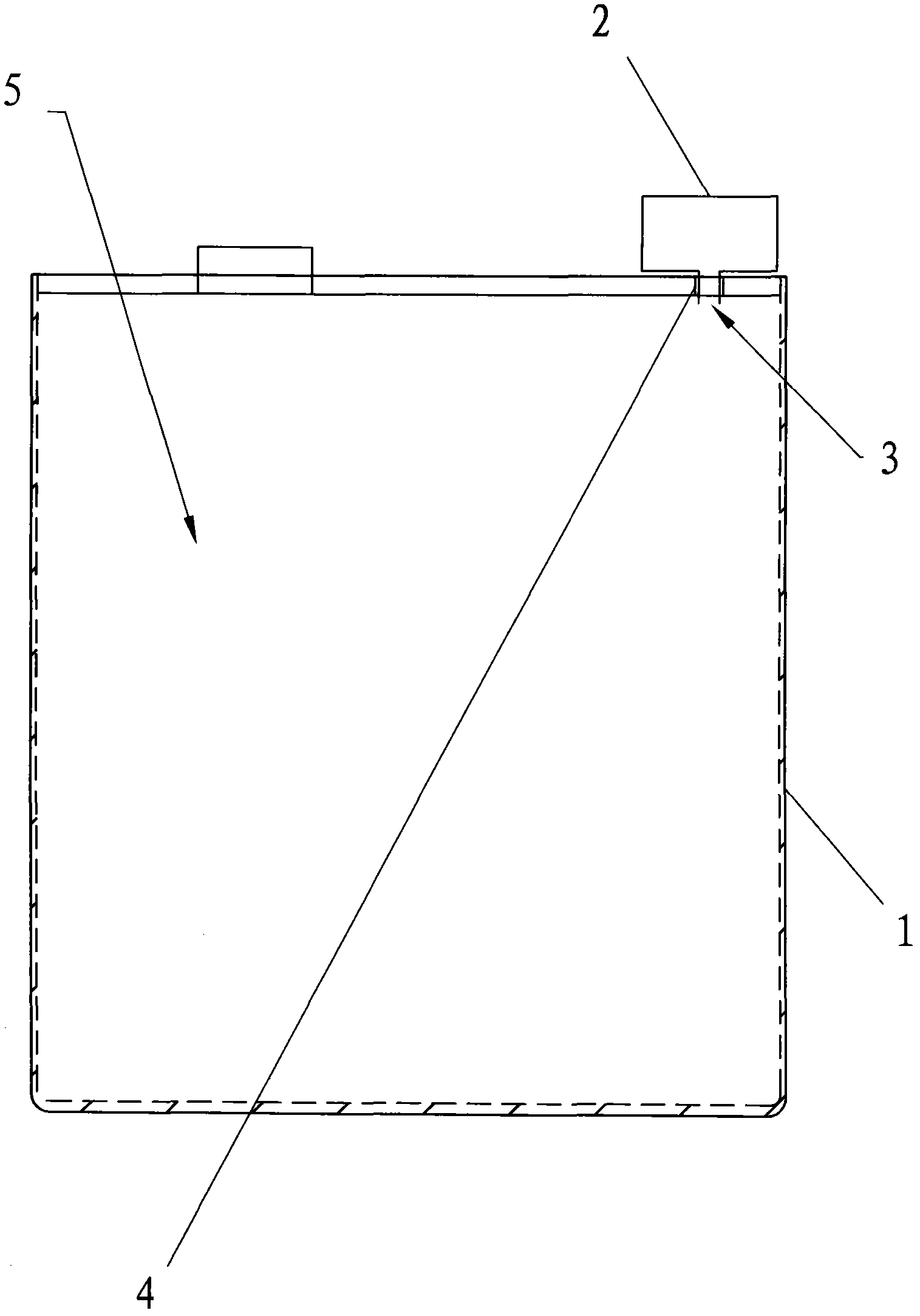

[0013] Below in conjunction with accompanying drawing, the present invention will be further described:

[0014] Such as figure 1 As shown, a secondary lithium ion battery according to the present invention has a structure as follows: it includes a battery case 1, a liquid injection space 5 is provided inside the battery case 1, and a connected liquid injection space 5 is provided inside the battery case 1 The liquid injection hole 4, which also includes an air bag 2 made of polypropylene film and injected with a sufficient amount of electrolyte, which can be called a PP air bag, the air bag 2 is provided with an opening 3, and one end of the opening 3 of the air bag 2 extends into Connected to the injection hole 4. Further, the connection between the opening 3 and the liquid injection hole 4 adopts a sealed structure to ensure that the electrolyte in the airbag 2 does not leak out and maintain the sealing of the liquid injection space 5 . Further, the opening 3 is an invert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com