Solid electrolytic capacitor and method for preparing the same

A technology of solid electrolyte and capacitor, applied in solid electrolytic capacitors, electrolytic capacitors, capacitors and other directions, can solve the problems of increasing the production cost of solid electrolytic capacitors, damaging capacitor elements 11, and deteriorating product characteristics, achieving low ESR and reducing bonding strength. The effect of deterioration and oxidation prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

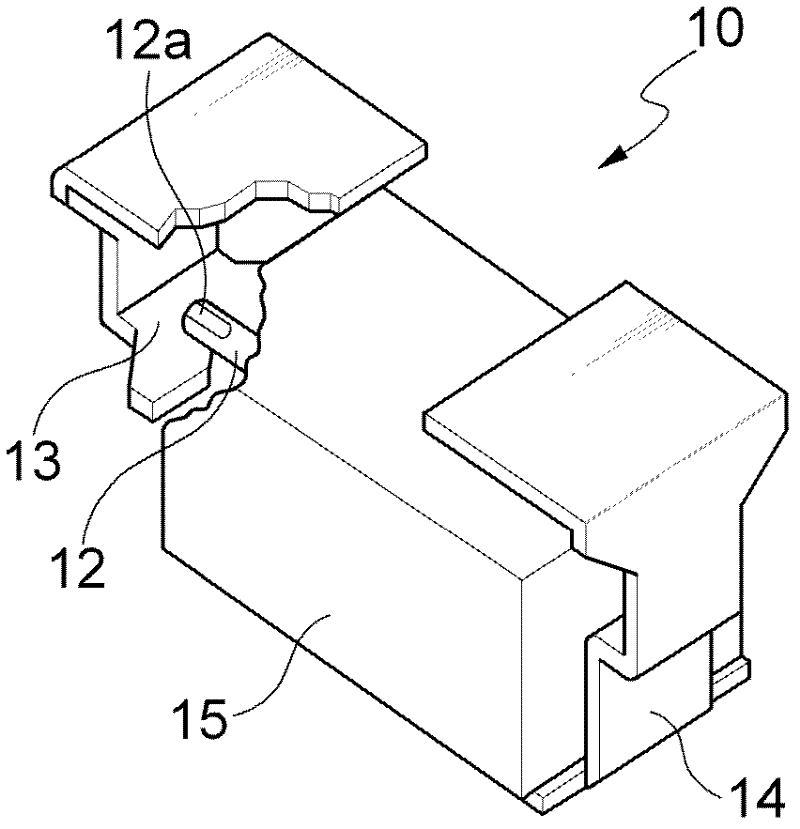

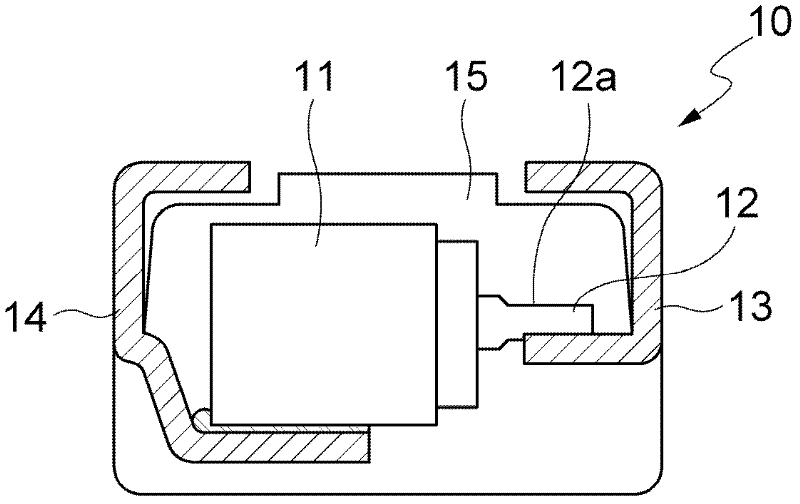

[0051] Hereinafter, specific embodiments of the present invention will be described with reference to the accompanying drawings. However, the following embodiments are provided as examples only, and are not intended to limit the present invention thereto.

[0052] Descriptions of well-known components and processing techniques are omitted so as not to unnecessarily obscure the embodiments of the invention. The following terms are defined in consideration of the functions of the present invention, and may be changed according to user's or operator's intention or custom. Therefore, these terms should be defined based on the contents described throughout this specification.

[0053] The technical idea of the present invention should be defined by the appended claims, and the following embodiments are merely examples for effectively conveying the technical idea of the present invention to those skilled in the art. .

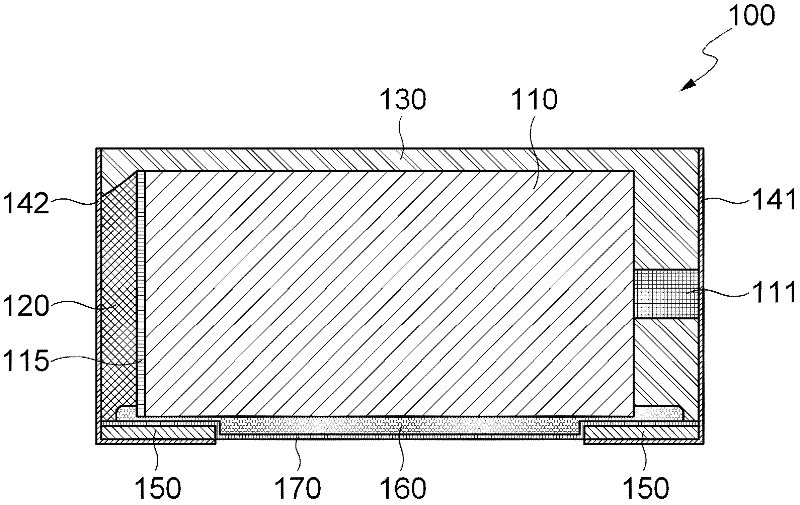

[0054] image 3 is a cross-sectional view of a solid ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com