Aqueous electrolyte, aqueous metal ion battery and preparation method thereof

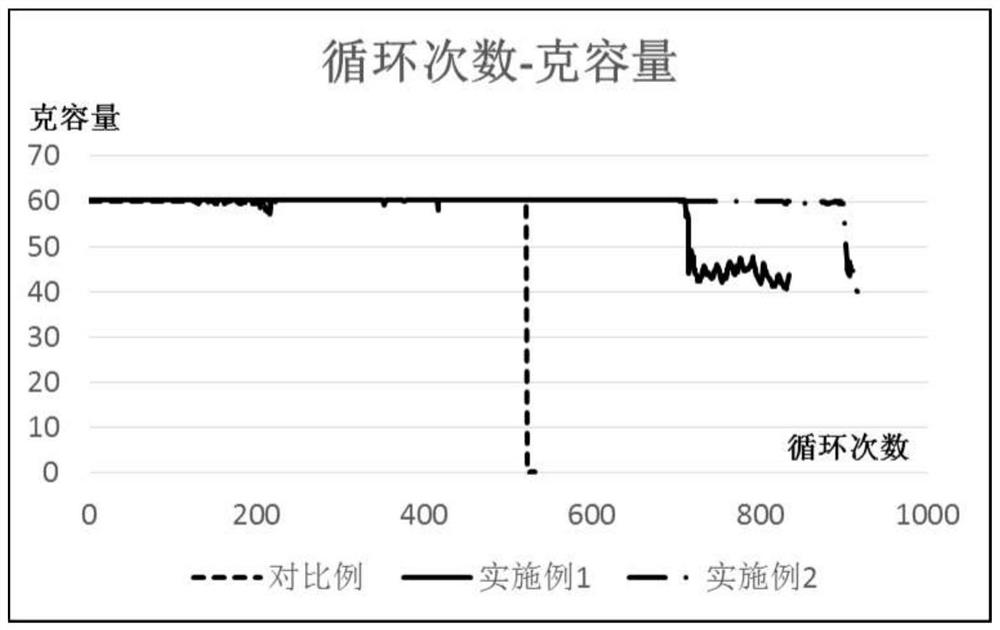

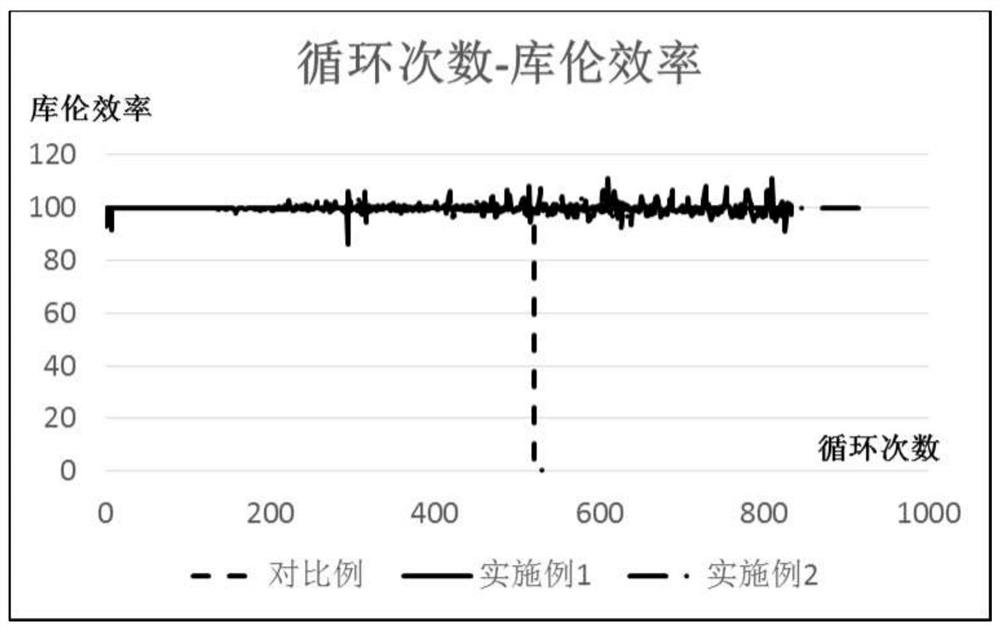

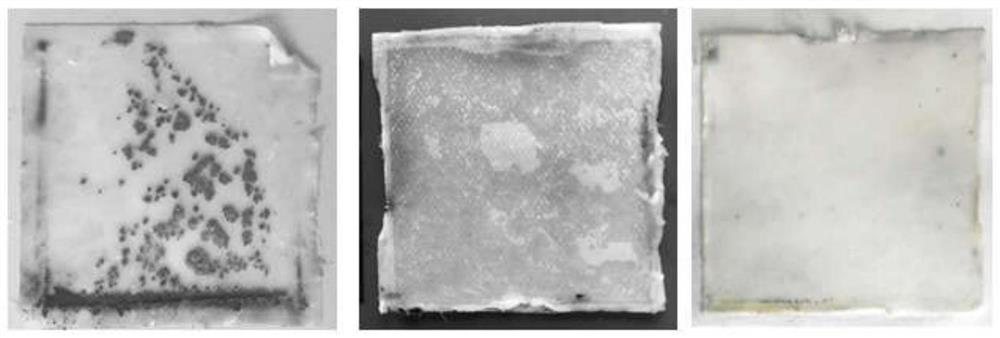

A water-based electrolyte and metal ion technology, applied in alkaline electrolytes, aqueous electrolytes, secondary batteries, etc., can solve problems such as battery failure, punctured diaphragm, short circuit, etc., to suppress deflagration, reduce capacity decay and improve uniformity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of using the above-mentioned water-based electrolyte to form a water-based metal ion battery comprises the following steps:

[0031] (1) The active material of the positive electrode, the conductive agent, and the binder are mixed evenly by high-speed stirring, ball milling or kneading, and then evenly coated on the positive electrode current collector by coating, pulping or kneading, and dried to obtain The positive electrode film attached to the positive electrode current collector is used as the positive electrode; the active material of the negative electrode, the conductive agent, and the binder are mixed evenly by high-speed stirring, ball milling or kneading, and then coated, pulped or opened. The method is to apply evenly on the negative electrode current collector, and dry to obtain the negative electrode film attached to the negative electrode current collector, which is used as the negative electrode; (2) The prepared positive electrode,...

Embodiment 1

[0034] Lithium manganate, conductive carbon black, and binder are mixed evenly by kneading in a mass fraction ratio of 8:1:1, wherein the binder is polytetrafluoroethylene; The method is evenly compacted on the stainless steel net, and dried to obtain the positive electrode film, which is used as the positive electrode; the metal-modified zinc powder (99% of the zinc powder, the rest is Bi and In), the conductive agent and the binder are mixed by kneading. Mix evenly according to the mass fraction ratio of 8:1:1, wherein the conductive agent is a mixture of conductive carbon black, carbon nanotubes and activated carbon, and the binder is polytetrafluoroethylene; Evenly compacted on the stainless steel mesh by the practice method, and dried to obtain the negative electrode film, which was used as the negative electrode.

[0035] Mix zinc sulfate, lithium sulfate and deionized water, stir magnetically for 15 minutes, then add propylene glycol additive, and stir for 1 hour to pre...

Embodiment 2

[0037] Lithium manganate, conductive carbon black, and binder are mixed evenly by kneading in a mass fraction ratio of 8:1:1, wherein the binder is polytetrafluoroethylene; The method is evenly compacted on the stainless steel net, and dried to obtain the positive electrode film, which is used as the positive electrode; the metal-modified zinc powder (99% of the zinc powder, the rest is Bi and In), the conductive agent and the binder are mixed by kneading. Mix evenly according to the mass fraction ratio of 8:1:1, wherein the conductive agent is a mixture of conductive carbon black, carbon nanotubes and activated carbon, and the binder is polytetrafluoroethylene; Evenly compacted on the stainless steel net in the way of training, and dried to obtain the negative electrode film, which is used as the negative electrode;

[0038] Mix zinc sulfate, lithium sulfate and deionized water, stir magnetically for 15 minutes, then add pyridine additive, stir for 1 hour, the concentration o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com