Laying hen laying peak period compound feed and production method thereof

A technology of compound feed during the peak egg production period, which is applied to the field of compound feed and its production during the peak egg production period, can solve the problems of large loss of heat-sensitive raw material components, excessive mycotoxin content in products, and reduced production performance of laying hens, etc., to achieve Avoid harm to laying hens, significant social value and economic value, and increase the effect of economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] A compound feed for laying hens during the peak laying period includes high-temperature granulation once, the granulation temperature is controlled at 83°C, and the granulation process is basically the same as the existing granulation method. One-time crushing, mixing, granulation and crushing at room temperature. The main raw materials for the first granulation are:

[0077] Raw material % by weight

[0078] Corn 45.48%

[0079] Flour 3%

[0080] Peanut meal 6%

[0081] Full Fat Rice Bran 15%

[0082] 40% cotton meal 2.49%

[0083] Distiller's grains 12%

[0084] Corn Germ Tortilla 3%

[0085] 60% Corn Gluten Meal 1.4%

[0087] The product of the first granulation is the base material for laying hens.

[0088] The raw materials for mixed granulation at room temperature include: 89.87 parts of the product (laying hen base material) after the first granulation and the following raw materials, which are subjected to secondary granulati...

Embodiment 2

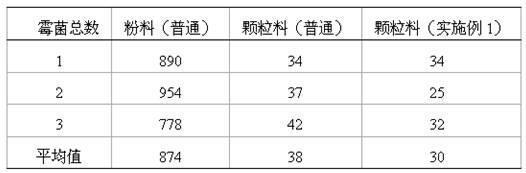

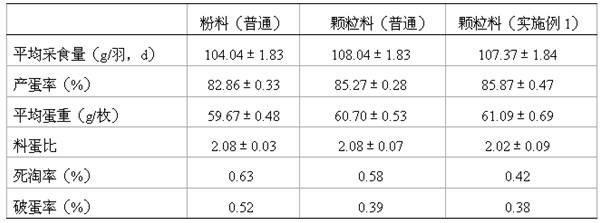

[0107] In order to verify the use effect of the layer hen compound feed produced by this method, the present embodiment adopts the same formula to test and verify the effects of layer hen powder, layer hen pellets and the compound feed described in Example 1 on the production performance and performance of layer hens. effect on digestion and absorption.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com