Non-fried coarse cereal instant noodles

An instant noodle, non-fried technology, applied in application, food preparation, food science, etc., can solve the problems of inability to meet nutritional diversification, nutrient destruction, single nutritional composition, etc., to avoid hidden dangers to human health and increase the amino acid score. , the effect of improving nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

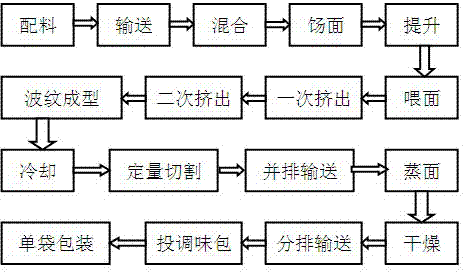

Image

Examples

Embodiment 1

[0015] Embodiment 1: a kind of non-fried miscellaneous grain instant noodles, it is characterized in that, described miscellaneous grain instant noodle weight ratio is: mung bean flour 10%, potato starch 26%, buckwheat flour 20%, corn flour 16%, wheat flour 18%, sweet potato Powder 10%.

[0016] In order to solve the loose quality of miscellaneous grain instant noodle cakes, appropriate compound additives can be added, and the best ratio of additives is: modified starch: 65.8%, compound phosphate: 5.7%, gluten enhancer: 21.9%, emulsifier : 6.6%.

[0017] The present invention is produced by an extrusion aging process, so that the material is extruded by the screw in the machine barrel and aged at a relatively high temperature, which not only achieves the effect of disinfection and sterilization, but also does not cause puffing of the material, and then undergoes corrugation forming, cooling, Quantitative cutting, re-steaming, drying, and bagging are made by a series of proces...

Embodiment 2

[0019] Embodiment 2: a kind of non-fried miscellaneous grain instant noodles, it is characterized in that, described miscellaneous grain instant noodle weight ratio is: mung bean flour 2%, potato starch 26%, buckwheat flour 22%, corn flour 18%, wheat flour 20%, sweet potato Powder 12%.

[0020] In order to solve the loose quality of miscellaneous grain instant noodle cakes, appropriate compound additives can be added, and the best ratio of additives is: modified starch: 65.8%, compound phosphate: 5.7%, gluten enhancer: 21.9%, emulsifier : 6.6%.

[0021] The present invention is produced by an extrusion aging process, so that the material is extruded by the screw in the machine barrel and aged at a relatively high temperature, which not only achieves the effect of disinfection and sterilization, but also does not cause puffing of the material, and then undergoes corrugation forming, cooling, Quantitative cutting, re-steaming, drying, and bagging are made by a series of process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com