Method for preparing granular sludge added with Mn2+

A technology of granular sludge and activated sludge, applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve problems such as low efficiency and short preparation cycle, and achieve high efficiency, short-term effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

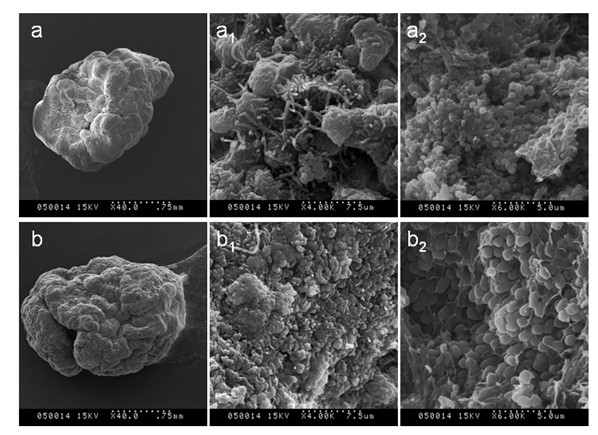

[0010] The addition of Mn in the present invention 2+ The preparation method of granular sludge is prepared by using a cylindrical SBR reactor. The activated sludge from the sewage treatment plant (the MLSS value of the activated sludge is 2g / L-2.5g / L, the MLVSS value is 1.5g / L-1.9g / L, and the SVI value is 92mg / L-96 mg / L mg / L at room temperature (25 o C--28 o C) Culture. Using tap water as a solvent to add glucose and trace elements to prepare a nutrition accelerator, the specific composition and content of glucose and trace elements are: MnCl 2 .H 2 O (7.86~52.36) mg / L, C 6 h 12 o 6 700 mg / L, NH 4 Cl 125 mg / L, K 2 HPO 4 42 mg / L, CaCl 2 4.5 mg / L, H 3 BO 3 50mg / L, NiCl 2 ·6H 2 O 50mg / L, (NH 4 ) 6 Mo 7 o 24 4H 2 O 120mg / L, CuSO 4 ·5H 2 O 30mg / L, CoCl 2 ·6H 2 O 70mg / L, AlCl 3 50mg / L, ZnSO 4 ·7H 2 O 50mg / L and MgSO 4 ·7H 2 O 10mg / L. When the cylindrical SBR reactor is in operation, the nutrient accelerator and aeration air enter from the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com