Method for forming lithium ion battery with mixed electrode

A technology of lithium ion battery and formation method, applied in the field of formation of lithium ion battery, can solve the problems of decreased battery durability, insufficient SEI film formation, irreversible insertion of lithium ions, etc., to improve stability, shorten formation time, and improve Effects of stability and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

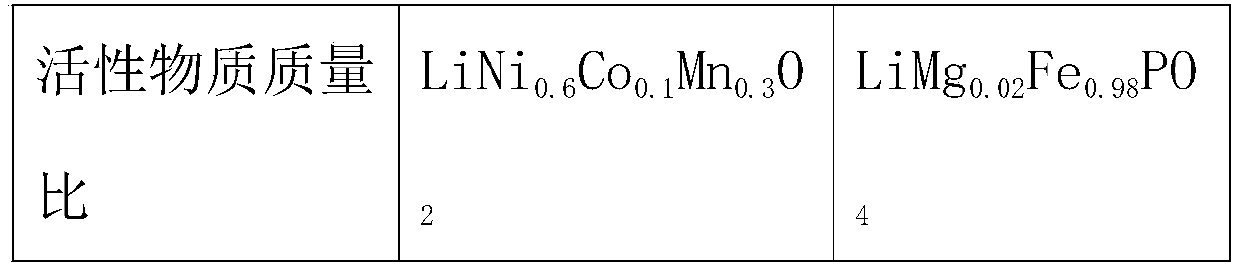

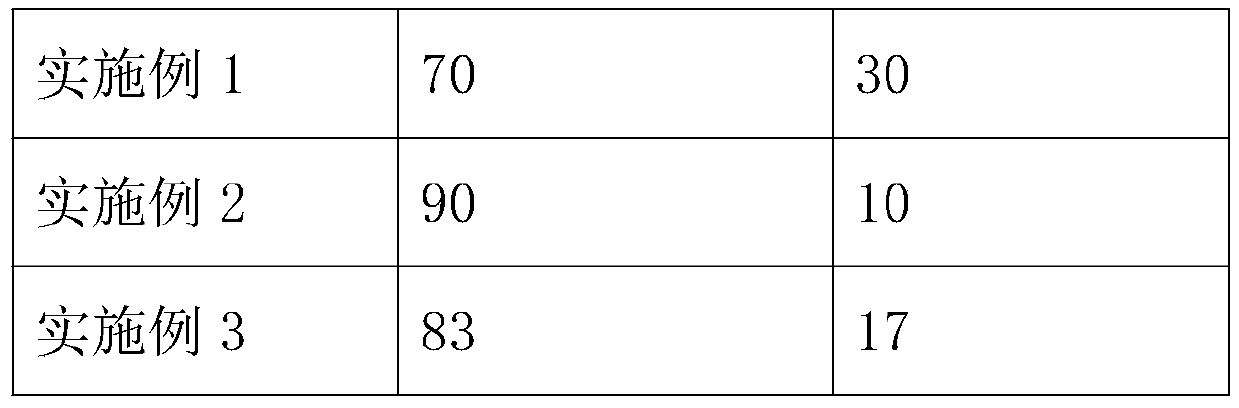

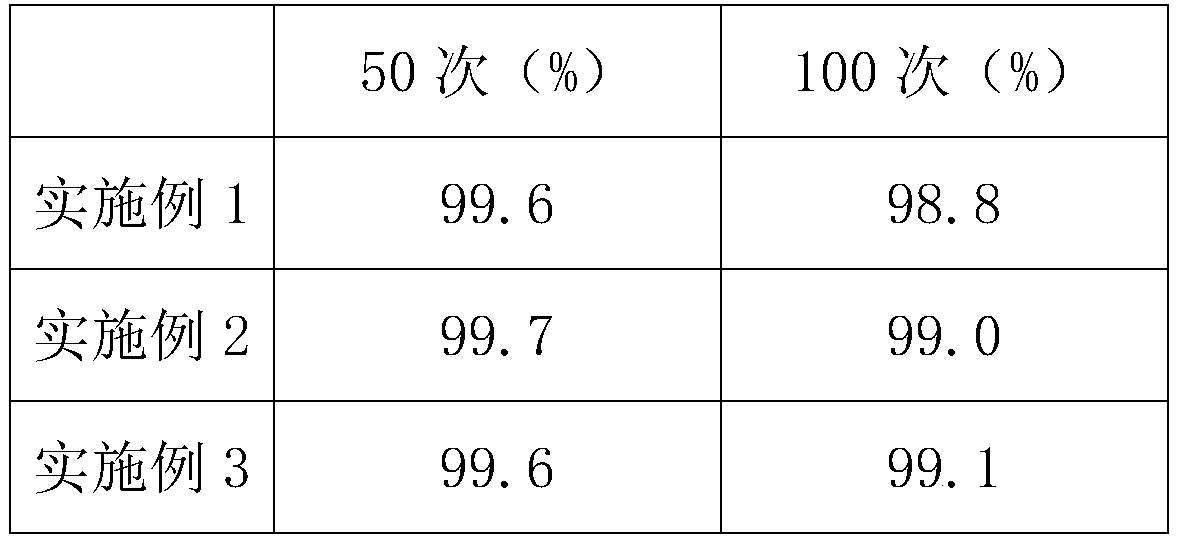

Embodiment 1

[0037] 1) Charge to 2.9V with a constant current of 0.01C;

[0038] 2) Charge to 3.55V with a constant current of 0.02C;

[0039] 3) In the range of 3.55-3.65V, charge and discharge 4 times with a constant current of 0.05C;

[0040] 4) Charge to 3.7V with a constant current of 0.05C;

[0041] 5) In the range of 3.70-3.90V, charge and discharge 4 times with a constant current of 0.02C;

[0042] 6) Charge with a constant current of 0.05C to the charging cut-off voltage, and the charging cut-off voltage is 4.2V;

[0043] 7) Charge with a constant voltage at the charge cut-off voltage until the charge current is lower than 0.01C;

[0044] 8) Discharge to 3.7V with a constant current of 0.05C;

[0045] 9) In the range of 3.70-3.90V, charge and discharge 4 times with a constant current of 0.05C;

[0046] 10) Discharge at a constant current of 0.05C to 3.55V;

[0047] 11) In the range of 3.55-3.65V, charge and discharge 4 times with a constant current of 0.1C;

[0048] 12) Dis...

Embodiment 2

[0051] 1) Charge to 3.0V with a constant current of 0.02C;

[0052] 2) Charge to 3.55V with a constant current of 0.05C;

[0053] 3) In the range of 3.55-3.65V, charge and discharge 4 times with a constant current of 0.1C;

[0054] 4) Charge to 3.7V with a constant current of 0.1C;

[0055] 5) In the range of 3.70-3.90V, charge and discharge 4 times with a constant current of 0.05C;

[0056] 6) Charge with a constant current of 0.1C to the charging cut-off voltage, and the charging cut-off voltage is 4.3V;

[0057] 7) Charge with a constant voltage at the charge cut-off voltage until the charge current is lower than 0.01C;

[0058] 8) Discharge to 3.7V with a constant current of 0.1C;

[0059] 9) In the range of 3.70-3.90V, charge and discharge 4 times with a constant current of 0.1C;

[0060]10) Discharge at a constant current of 0.1C to 3.55V;

[0061] 11) In the range of 3.55-3.65V, charge and discharge 4 times with a constant current of 0.2C;

[0062] 12) Dischargin...

Embodiment 3

[0065] 1) Charge to 3.0V with a constant current of 0.01C;

[0066] 2) Charge to 3.55V with a constant current of 0.03C;

[0067] 3) In the range of 3.55-3.65V, charge and discharge 4 times with a constant current of 0.06C;

[0068] 4) Charge to 3.7V with a constant current of 0.06C;

[0069] 5) In the range of 3.70-3.90V, charge and discharge 4 times with a constant current of 0.02C;

[0070] 6) Charge with a constant current of 0.06C to the charging cut-off voltage, and the charging cut-off voltage is 4.25V;

[0071] 7) Charge with a constant voltage at the charge cut-off voltage until the charge current is lower than 0.01C;

[0072] 8) Discharge to 3.7V with a constant current of 0.06C;

[0073] 9) In the range of 3.70-3.90V, charge and discharge 4 times with a constant current of 0.05C;

[0074] 10) Discharge at a constant current of 0.1C to 3.55V;

[0075] 11) In the range of 3.55-3.65V, charge and discharge 4 times with a constant current of 0.15C;

[0076] 12) Di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com