Glass flow control device and method for prolonging service life of glass flow control device

A control device and flow rate technology, which is applied in glass manufacturing equipment, glass furnace equipment, manufacturing tools, etc., can solve problems such as bubbling at the contact point, alloy cracking, and mechanical strength decline, so as to prevent bubbling, prolong service life, Improve the effect of erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

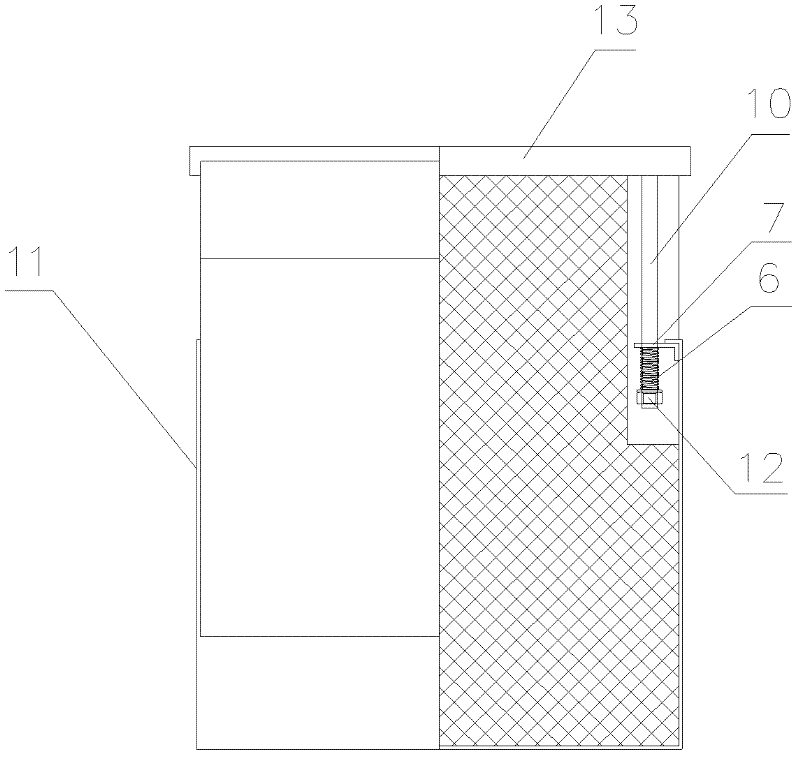

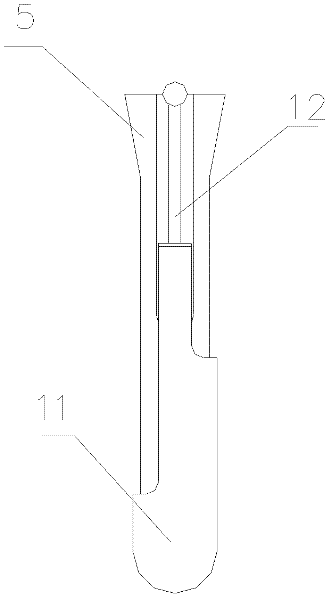

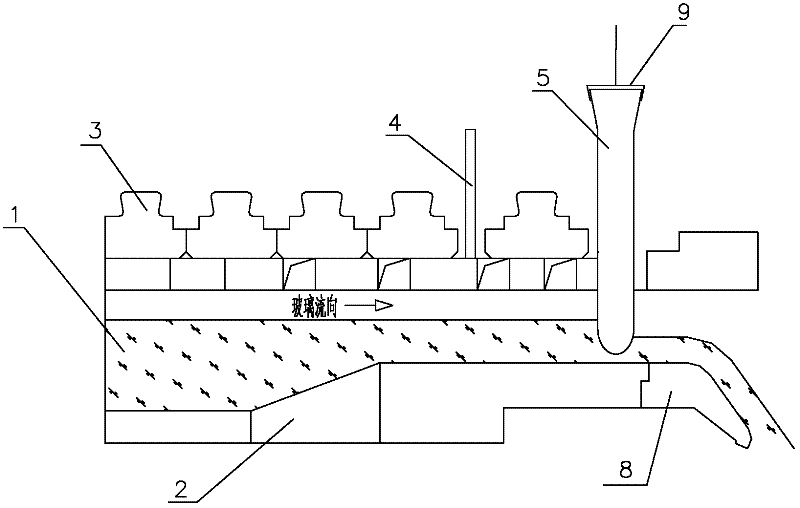

[0021] like figure 1 and figure 2 As shown, the glass flow control device of the present invention covers a layer of platinum-rhodium alloy layer 11 on the outer surface of the existing shutter 5, and the thickness of the platinum-rhodium alloy layer 11 is preferably 0.65-1.0mm, more preferably 0.7- 0.9mm. The weight percent content of rhodium in the platinum-rhodium alloy layer 11 is preferably 5-15%.

[0022] Platinum-rhodium alloy layer 11 is set in such a way that it wraps up from the bottom of gate 5, and the height of platinum-rhodium alloy layer 11 is at least above the liquid level of glass liquid 1, so that gate 5 does not directly contact glass liquid 1, preventing gate 5 is corroded by glass liquid 1.

[0023] An elastic device 12 is provided on both sides of the flow control device of the present invention, and the upper end of the platinum-rhodium alloy layer 11 is connected to the elastic device 12 . Specifically, elastic device 12 can be made up of spring 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com