Coke oven crude gas waste heat recycling method and dedicated heat exchange type ascending tube

A waste heat recovery and waste gas technology, which is applied to the heating of coke ovens, coke ovens, indirect heat exchangers, etc. Flexible operation and outstanding energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

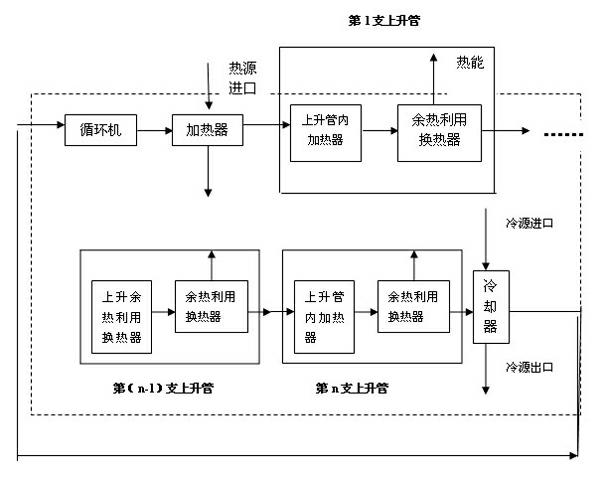

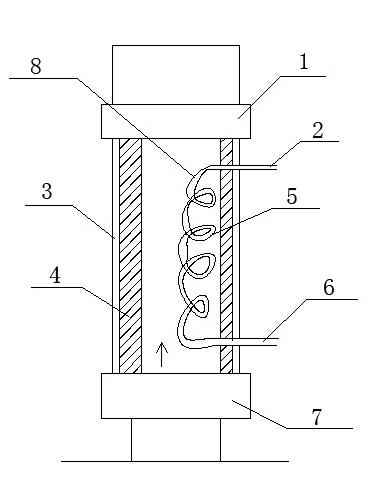

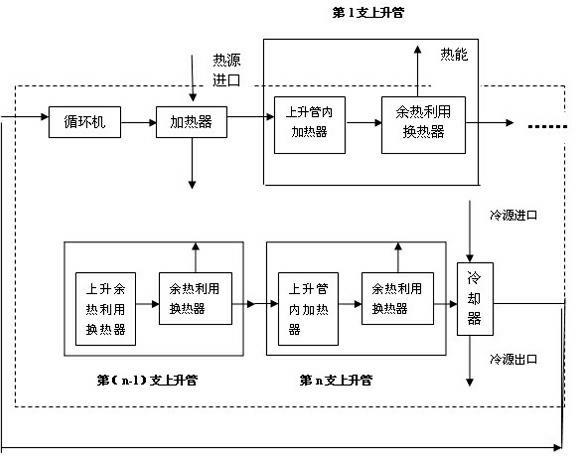

[0024] In this embodiment, a coke oven raw gas waste heat recycling method uses gas as the heat exchange medium, and after being pressurized by the circulator, it enters the heat exchanger in the rising pipe through the gas outlet; in the heat exchanger in the rising pipe, The gas is heated by high-temperature gas, and the gas is cooled by the gas and flows out of the riser; the heated gas flows out of the heat exchanger in the riser, enters the waste heat utilization heat exchanger, releases heat energy, enters the cycle machine, pressurizes, and then enters the next cycle , and so on and on, the heat energy of the gas in the rising pipe of the coke oven is continuously taken out from the rising pipe by the gas, and is utilized by the waste heat heat exchanger. In view of the operating temperature requirements of the circulator, the heated gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com