Method for deeply separating tungsten and molybdenum from high-tungsten and high-molybdenum mixed solution

A mixed solution, high tungsten technology, applied in the direction of process efficiency improvement, etc., can solve the problems of growth, no separation effect of tungsten and molybdenum, effective adsorption of resin, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

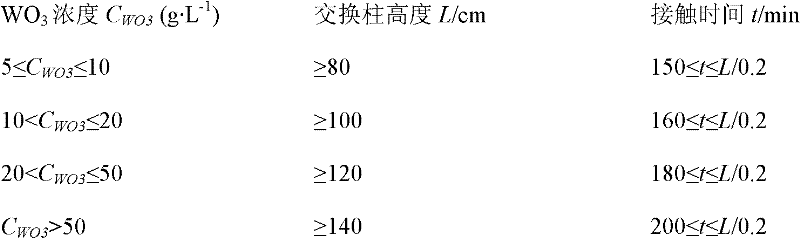

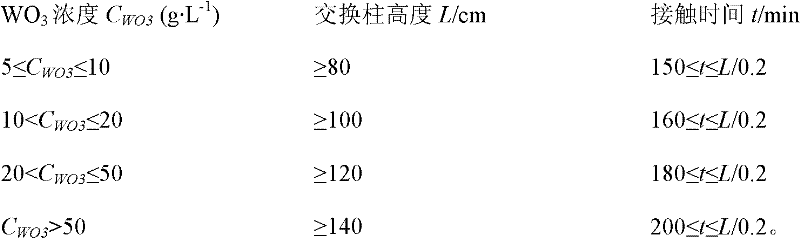

Embodiment 1

[0060] Example 1 The mixed solution of sodium tungstate and sodium molybdate, after adjusting its pH to 7.2, contains WO 3 5.5g / L, Mo 20.4g / L, the solution has been transformed into NO 3 - The adsorption is carried out in the exchange column of macroporous weakly basic anion resin D301 equipped with fine particles, the height of the exchange column is 80cm, and the control contact time is 150min. During the adsorption process, Mo leaked through after passing through 3 times the resin volume of the feed liquid, and after passing through 11 times the resin volume of the feed liquid, WO 3 Leakage, the amount of molybdenum flowing out at this time accounts for 75.5% of the total inflow, and the Mo and WO in the post-handover liquid 3 The contents are 15.4g / L and 0.011g / L respectively.

Embodiment 2

[0061] Example 2 The mixed solution of sodium tungstate and sodium molybdate, after adjusting its pH to 7.3, contains WO 3 6.4g / L, Mo 19.1g / L, pass the solution through the - Adsorption is carried out in the exchange column of the macroporous weakly basic anion resin D314 of the fine particle type, and four short exchange columns with a column height of 50 cm are connected in series, and the contact time is controlled to be 200 min. During the adsorption process, Mo in the four exchange columns leaked through sequentially after passing through 0.8 times, 1.7 times, 2.6 times, and 3.5 times the resin volume feed liquid respectively, and passed through 2.1 times, 4.5 times, 8 times, and 12 times the resin volume feed liquid respectively. WO in the last four exchange columns 3 Leaked through sequentially, the amount of Mo flowing out accounted for 82.2% of the total inflow, and the molybdenum content in the post-handover liquid was 15.7g / L, WO3 The content is almost 0. The load...

Embodiment 3

[0062] The mixed solution of ammonium tungstate and ammonium molybdate that distills ammonia to pH of 7.6 in embodiment 3 contains WO 3 35.1g / L, Mo79.6g / L, the solution has been transformed into Cl at a constant speed - Adsorption is carried out in an exchange column equipped with macroporous weakly basic anion resin D301 of the fine particle type, the exchange column is 125cm long, and the contact time is controlled for 190min. After the adsorption process passes through 0.3 times the volume of the resin, Mo leaks through, and after passing through 3 times Resin volume of feed solution after WO 3 Leakage, the amount of Mo flowing out at this time accounts for 70.98% of the total inflow, Mo, WO in the post-handover liquid 3 The contents were 56.5g / L and 0.019g / L respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com