Trimming device and method

A technology of trimming device and pressing device, which is applied in the direction of textile and paper making, fabric surface trimming, processing textile material containers, etc., to achieve the effect of reducing cycle time and saving manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

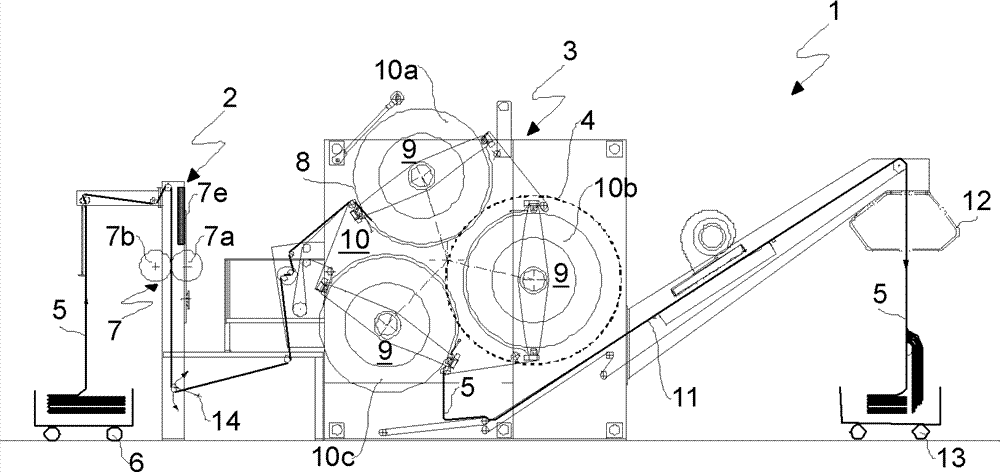

[0017] refer to figure 1 , The finishing device 1 of the present invention comprises a compacting unit 2 and a steaming unit 3 arranged downstream of the compacting unit 2, the steaming unit 3 having an autoclave 4 of closed type (indicated by dashed lines in the figure).

[0018] The web 5 to be treated is supplied to the compacting unit 2 from a container 6 arranged upstream of the compacting unit 2 .

[0019] The compacting unit 2 comprises a compacting device 7 provided, for example, with at least one pair of counter-rotating cylinders 7a, 7b adapted to reduce the thickness of the fabric 5 in a predetermined manner. As is known, one or more cylinders of the compaction unit 2 are heated in order to be able to stabilize the reduced thickness of the fabric 5 .

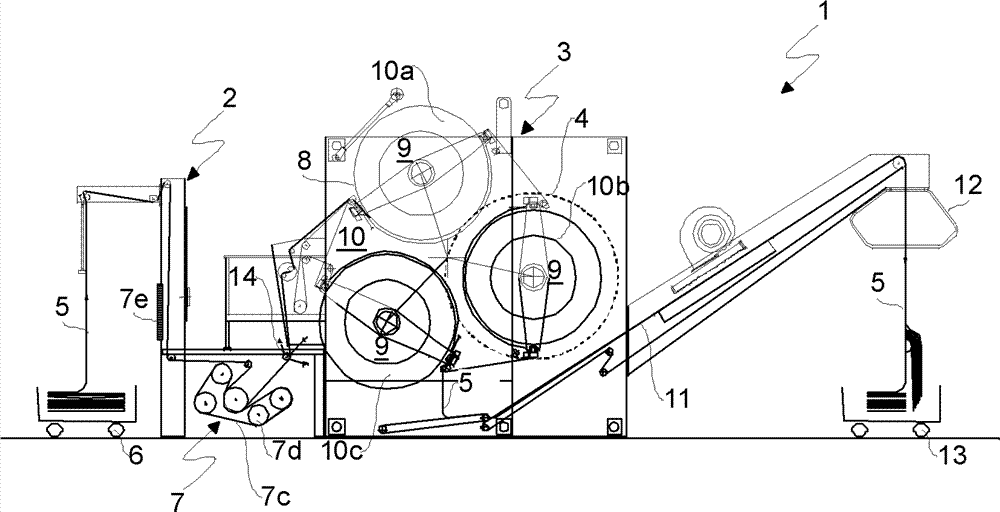

[0020] Such as figure 2 As an alternative to the counter-rotating cylinders 7a, 7b shown in the variant of the trimming device 1 shown in , the pressing device 7 may comprise a belt 7c supported by a plurality of r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com