Floor drain with functions of grinding and generating electricity

A floor drain and function technology, applied in the field of sanitary ware, can solve the problems of production, living inconvenience, blockage of drainage pipes, environmental pollution, etc., and achieve the effect of improving reliability and passing ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

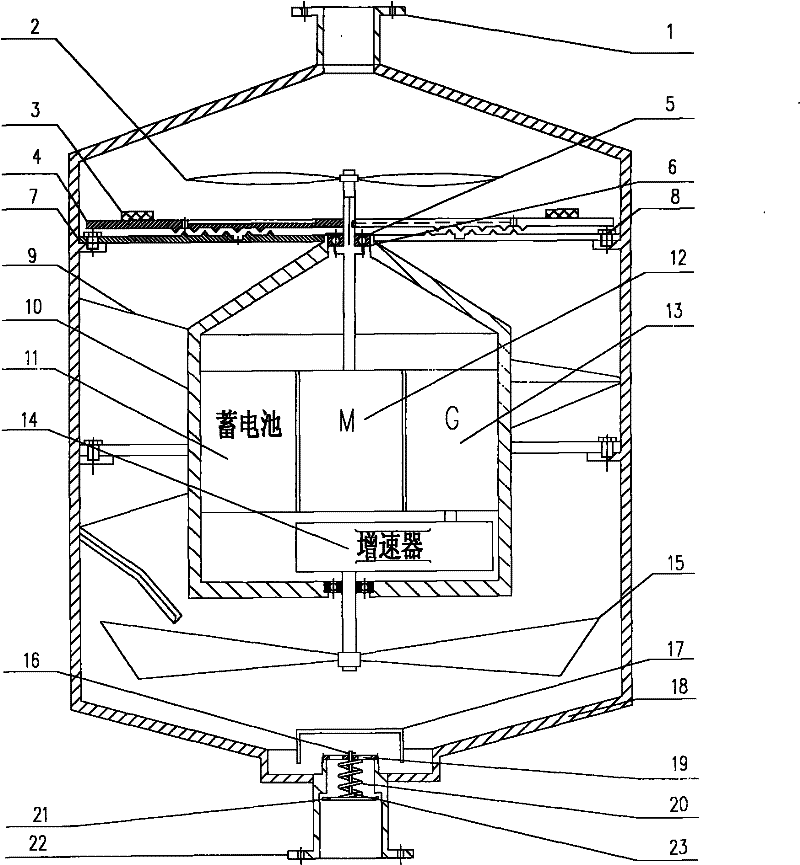

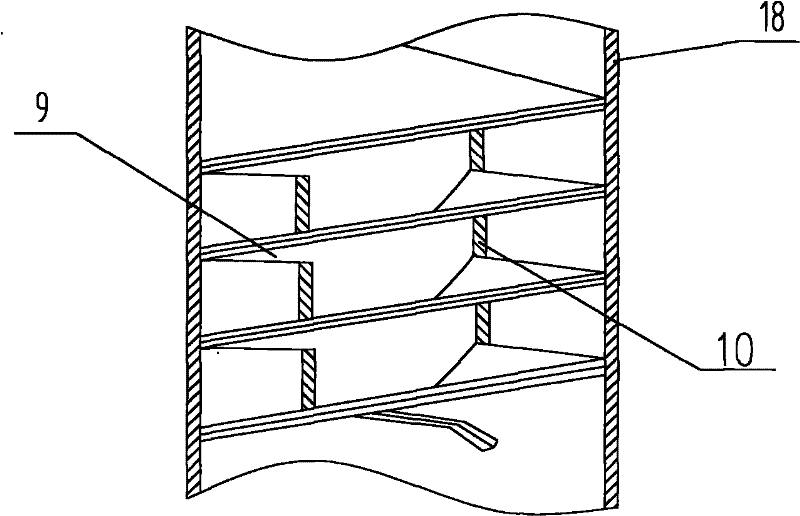

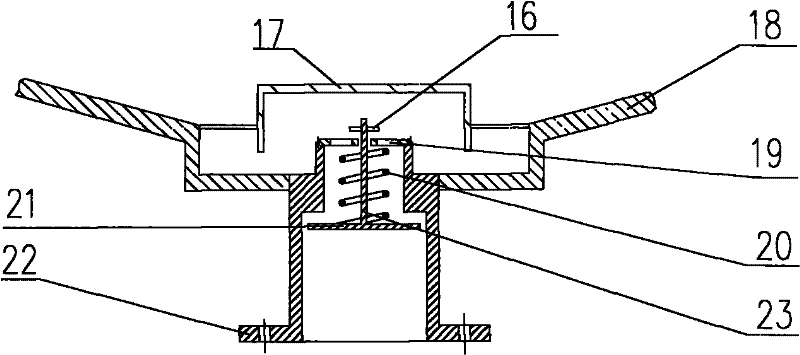

[0023] The general concept of the present invention is to use crushing blades, rotating grinding discs and fixed grinding discs to realize the crushing of wastes, which improves the reliability and throughput of the equipment; the use of annular diversion grooves makes the discharge of wastes faster, and the impact drives the power generation blades at a high speed. Rotate to generate electricity. Introduce a kind of embodiment below in conjunction with accompanying drawing: figure 1 Shown is a structural schematic diagram of an embodiment, consisting of an upper end cover 1, a crushing blade 2, a pressure sensor 3, a rotating grinding disc 4, a sealing ring 5, a rolling bearing 6, a fixed grinding disc 7, connecting bolts 8, an annular flow guide groove 9, an inner Box 10, battery 11, motor 12, generator 13, speed increaser 14, power generation blade 15, retaining spring 16, deodorant end cover 17, outer box 18, drainage inner cover 19, spring 20, sealing cover 21, The lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com