B-shaped aluminum tube belt type heat radiator for water tank

A technology of radiator and tube-belt type, applied in the direction of heat exchanger type, indirect heat exchanger, tubular element, etc., can solve the problems of increased pressure, high production scrap rate, reduced heat transfer performance, etc., to achieve enhanced pressure bearing capacity, low production scrap rate, and improved heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

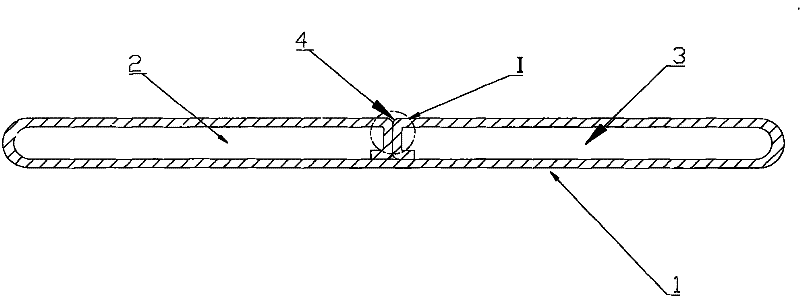

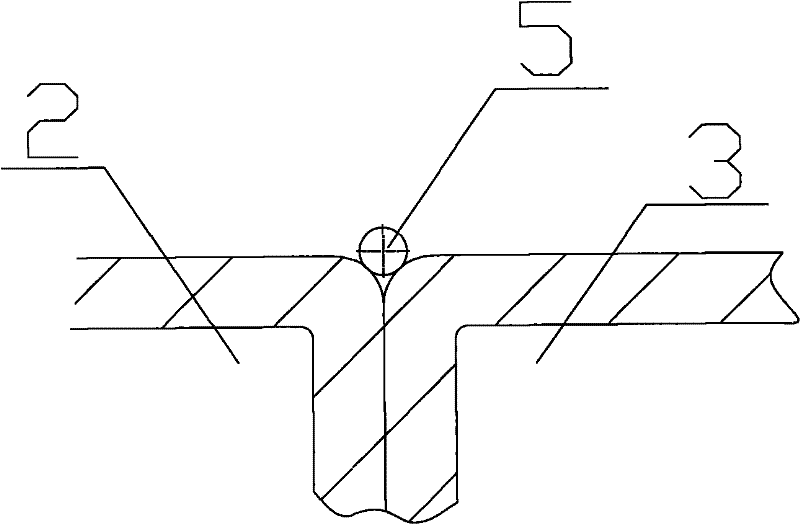

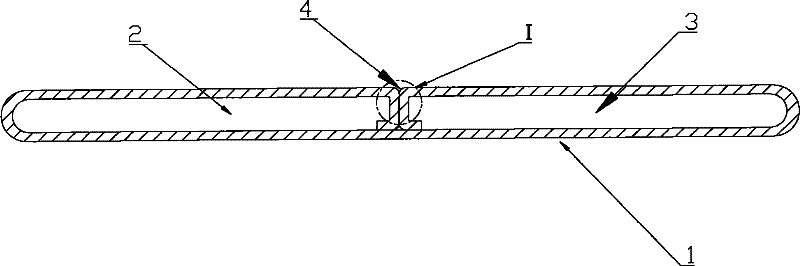

[0024] Such as Figure 1-2 As shown, a B-type tube aluminum tube belt type water tank radiator includes a heat dissipation pipe, a heat dissipation belt, a side plate and a main piece, and the heat dissipation pipe 1 is a B-type tube, and the B-type tube is folded in the middle The heat pipe is separated into two cavities: a cavity 2 and b cavity 3, so that the liquid circulates in two independent through cavities (a cavity 2 and b cavity 3), and the cladding layer is on the outside with the heat dissipation belt Connected, and the inner side is a smooth surface. The heat generated during the working process forms heat exchange with the outside through the heat dissipation belt connected to it, so as to improve the heat exchange efficiency.

[0025] In order to make the shape of the B-shaped tube not be affected by the width of the coil material, the middle rib adopts an overlapping angle structure. This also improves the weld strength of the ribs. In order to ensure the qua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com