MEMS silicon microphone longitudinally integrated with CMOS circuit, and manufacturing method for the same

A vertically integrated silicon microphone technology, applied to electrical components, sensors, microphone ports/microphone accessories, etc., can solve problems such as increased costs, reduced yields, and complicated manufacturing processes, so as to enhance reliability and simplify production Process, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with specific drawings and embodiments.

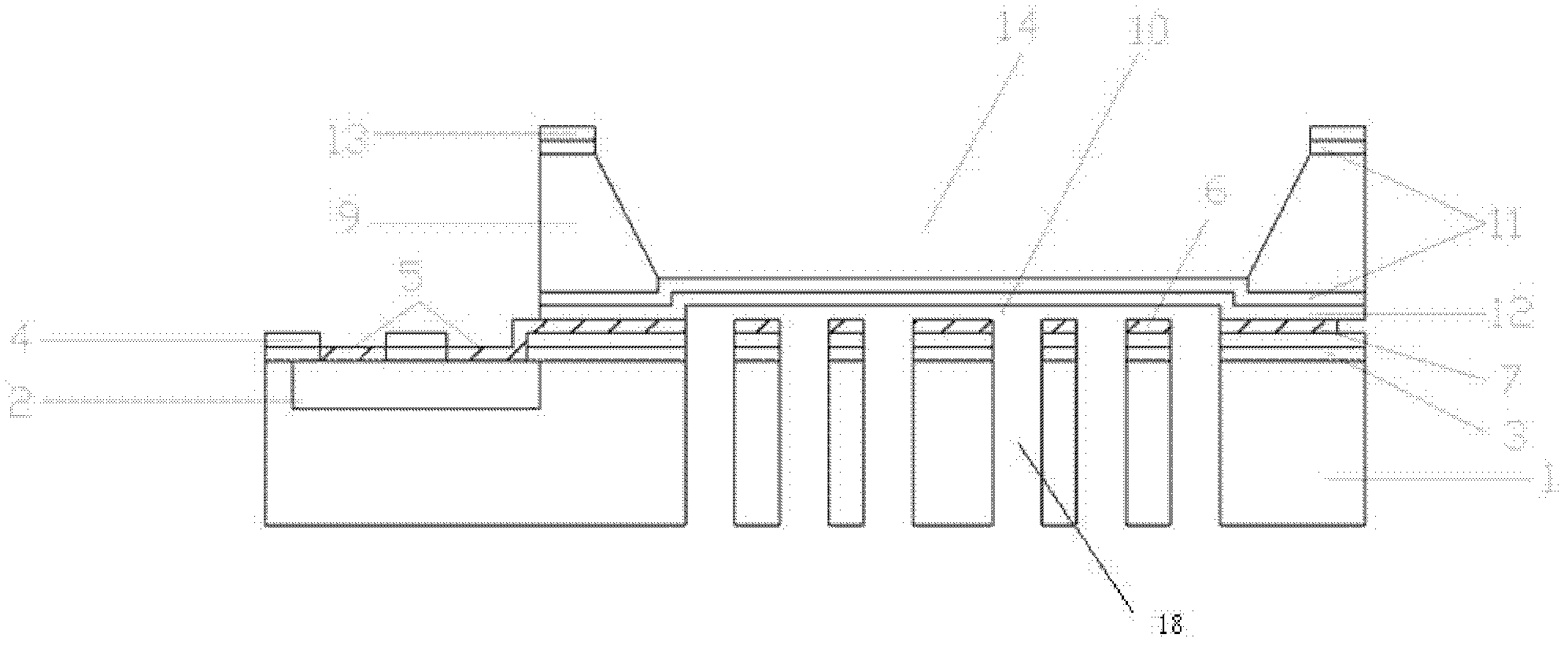

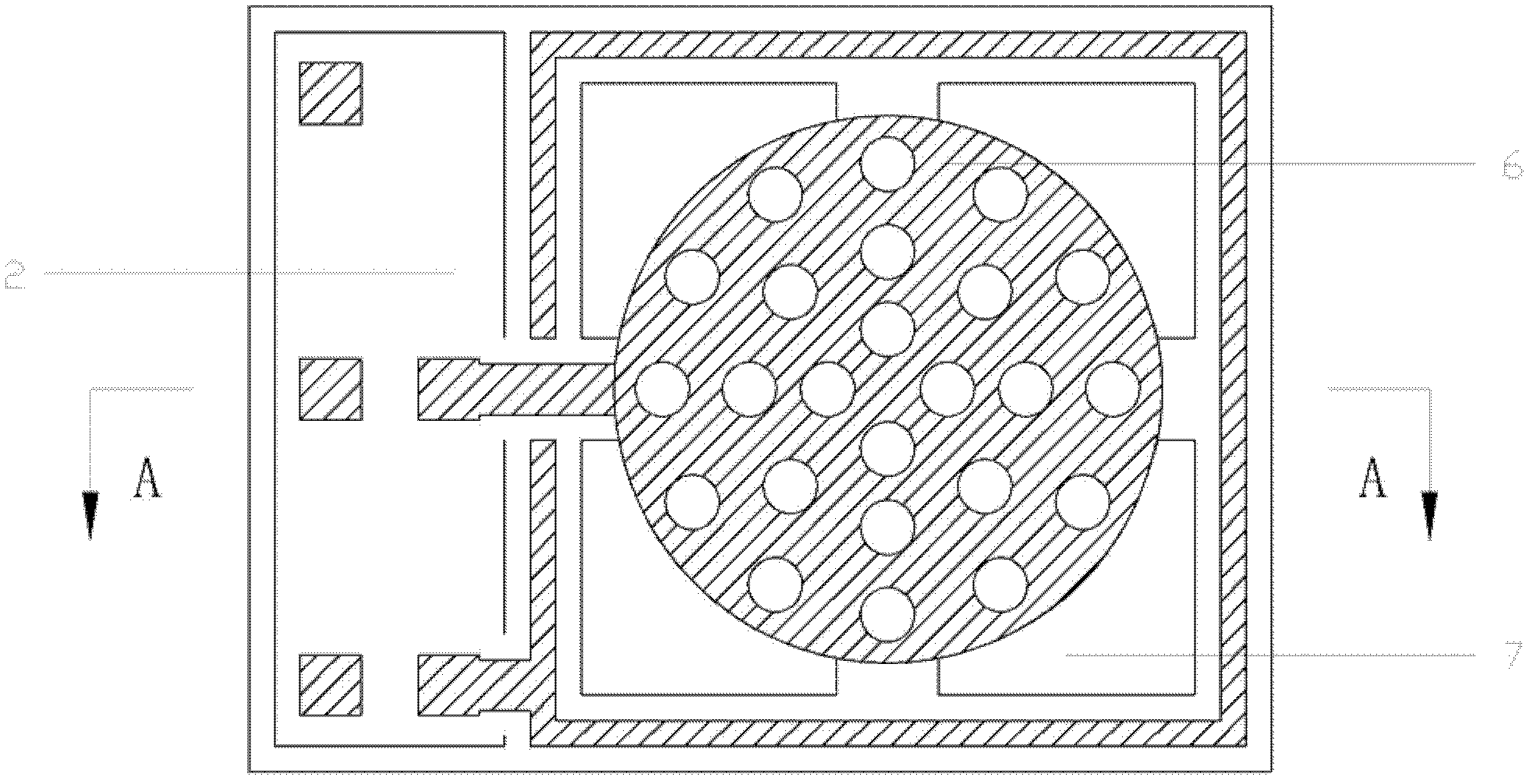

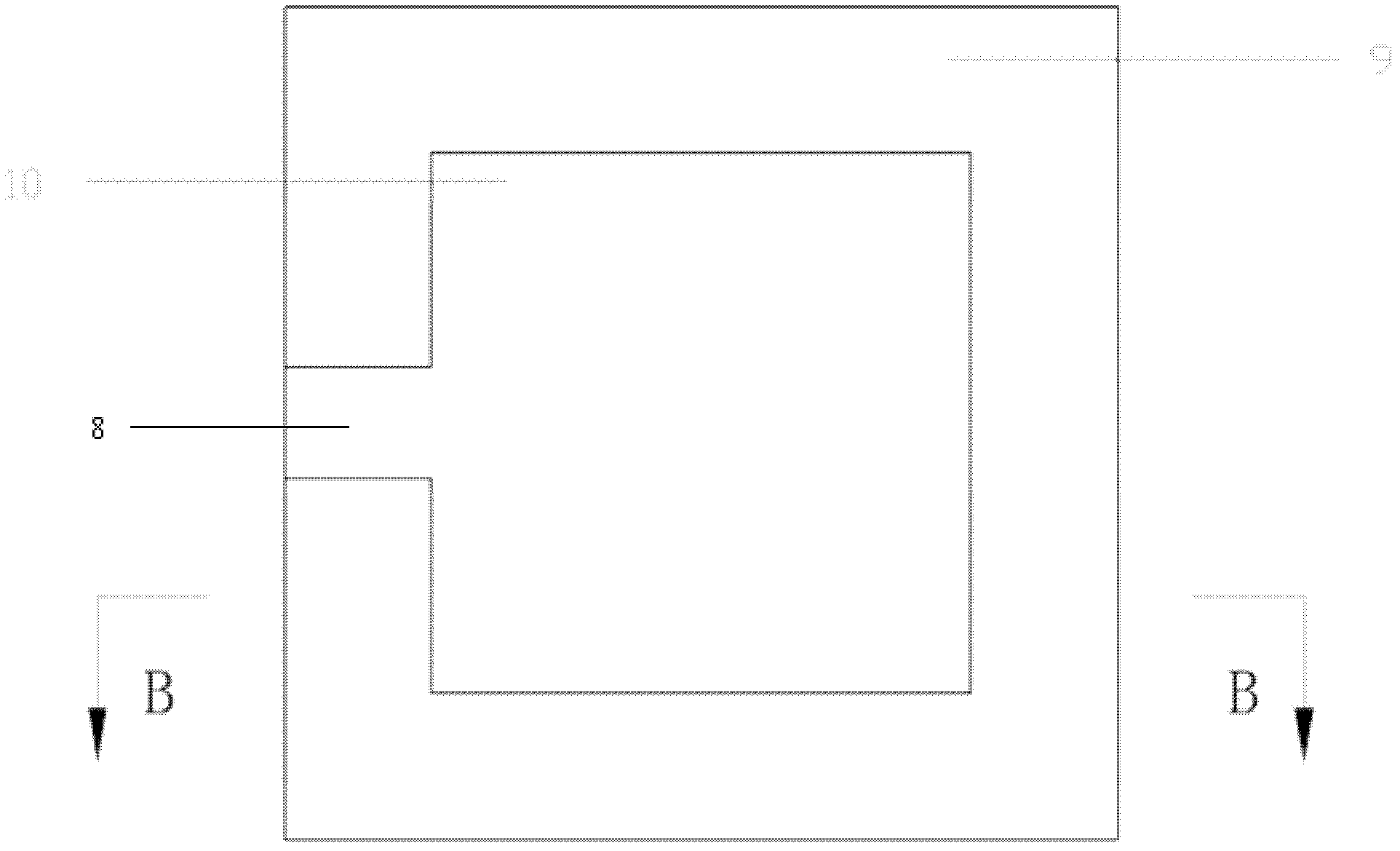

[0051] Such as Figure 1 to Figure 16 As shown: the present invention includes a back plate silicon substrate 1, a CMOS circuit 2, a first insulating dielectric layer 3, a second insulating dielectric layer 4, a connecting terminal 5, a lower electrode 6, a metal bonding layer 7, a shallow groove 8, a vibration Membrane silicon base 9, shallow pit 10, insulating support layer 11, diaphragm body thin film 12, mask layer 13, deep pit 14, input connection groove 15, output connection groove 16, positioning hole 17, deep hole 18, input end 19 , the output terminal 20 and the etching window 21.

[0052] Such as figure 1 and Figure 16 As shown: the MEMS silicon microphone includes a back plate and a diaphragm body located on the back plate. In the present invention, the back plate includes a back plate silicon base 1, and the back plate silicon base 1 is provided...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com