Polycrystalline diamond compact including a cemented tungsten carbide substrate that is substantially free of tungsten carbide grains exhibiting abnormal grain growth and applications therefor

A technology for polycrystalline diamond, grain growth, used in transportation and packaging, metal processing equipment, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

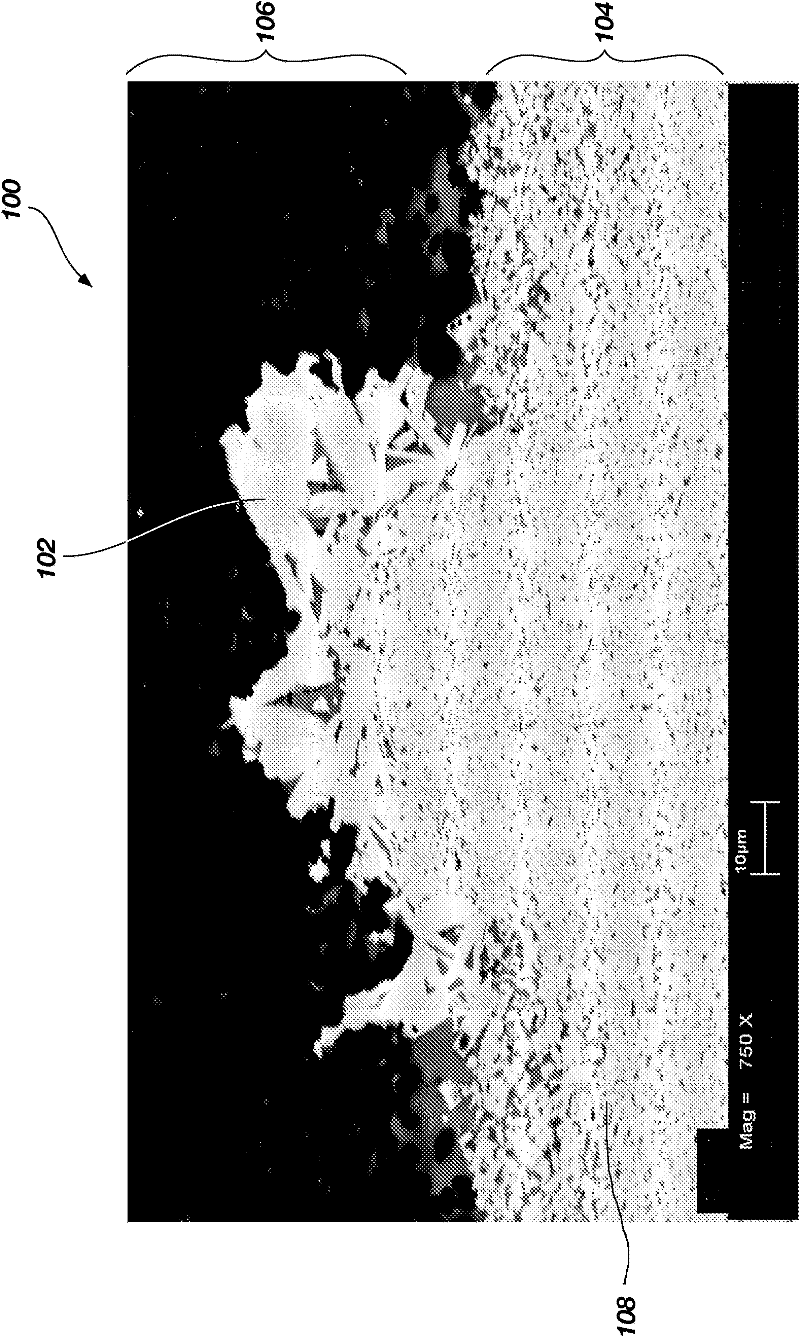

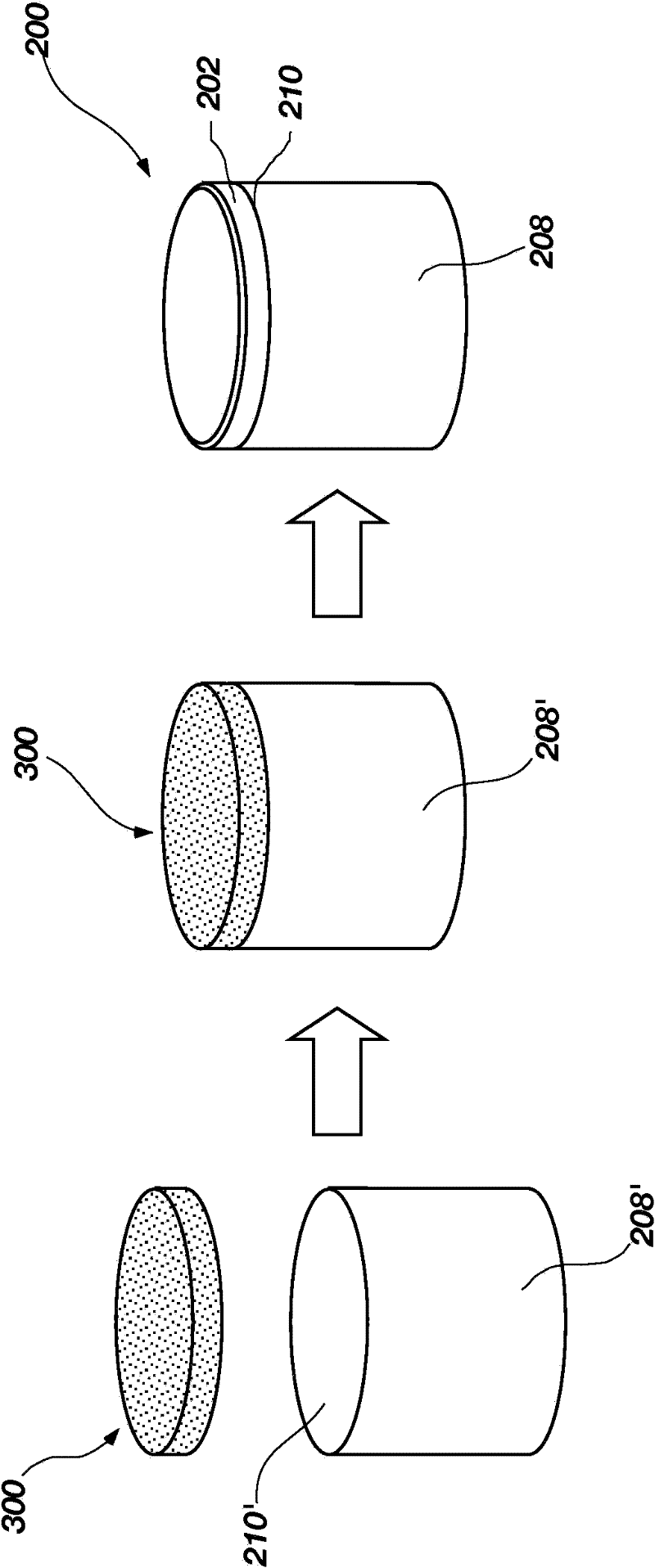

[0019] Embodiments of the invention relate to PDCs comprising PCD tables that are substantially free of defects formed from tungsten carbide grains exhibiting AGG by bonding PCD tables to sintered This PDC is fabricated by either forming a PCD table integrally with a sintered carbide substrate comprising one or more carbon-deficient tungsten-containing η Mutually. The disclosed PDCs can be used in a variety of applications such as rotary drill bits, processing equipment, and other items and devices.

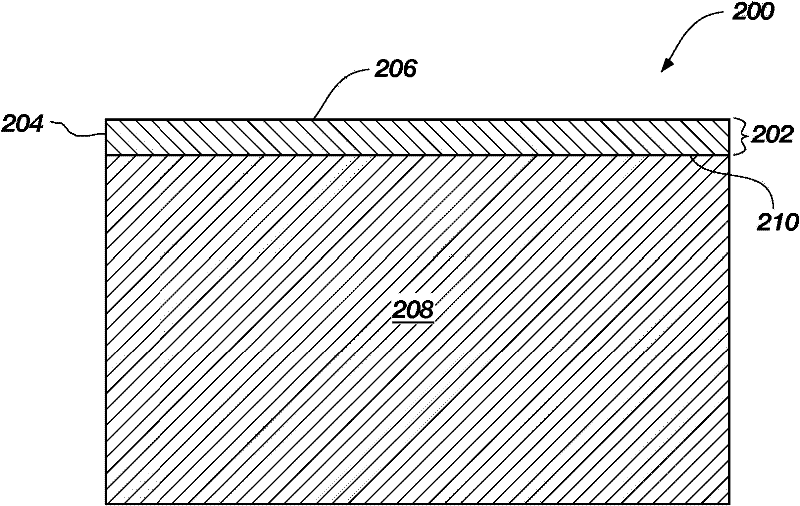

[0020] figure 2 is a cross-sectional view of an embodiment of a PDC 200 comprising a PCD table 202 integrally formed with a sintered tungsten carbide substrate 208 substantially free of tungsten carbide grains exhibiting AGG. The PCD table 202 contains a plurality of directly bonded diamond grains exhibiting diamond-to-diamond bonding therebetween, defining a plurality of interstitial regions. The microstructural and mechanical properties of the PCD table 202 are properties d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com