Method for connection, and connection of a capillary tube to a main tube

A technology of capillary tube and main tube, which is applied in the field of pre-order connection, can solve the problems of not being sure to keep completely unobstructed, long cooling time, long heating time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

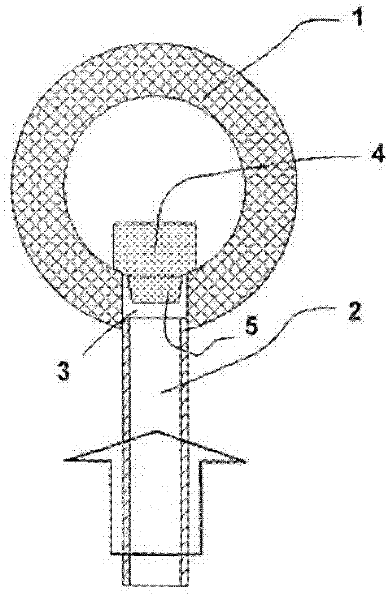

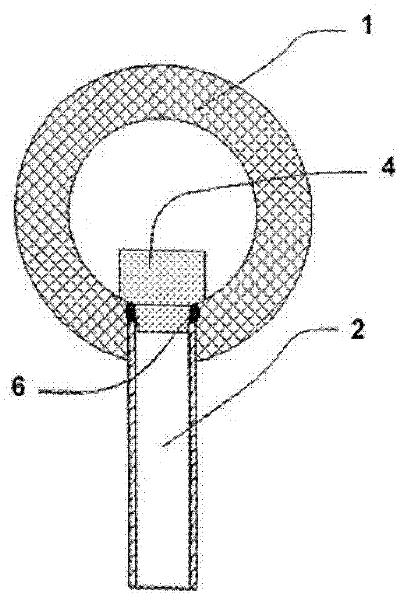

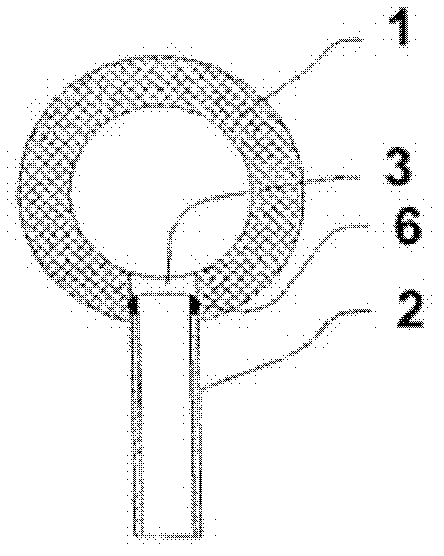

[0012] Figure 1a A cross-section of the main tube 1 and the capillary 2 to be connected to the main tube 1 is shown. In each case, the main pipes 1 as well as the capillary tubes 2 are made of plastic and are preferably used as components of heat exchanger pads for which the ends of a plurality of capillary tubes are connected on the one hand to the Or the main pipe of the cooling medium, on the other hand is connected to the main pipe for leading out the heating medium or cooling medium. A plurality of capillaries connected to the main pipe are arranged successively in the length direction of the main pipe, wherein ideally the distance between adjacent capillaries is as small as possible.

[0013] Typical dimensions for such a heat exchanger pad are main tube 1 with an outer diameter of 20 mm and an inner diameter of 16 mm, and capillary tubes 2 with an outer diameter of 3.0 mm and an inner diameter of 2.4 mm.

[0014] In this example, the main pipe has a circular cross-sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com