Packaging machine for twist drill

A packaging machine and twist drill technology, applied in the directions of packaging, wrapping paper, wrapping paper shrinkage, etc., can solve the problems of high labor intensity of workers, low packaging efficiency, and unsightly appearance of packaging, and reduce labor intensity of workers and improve production efficiency. , the effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

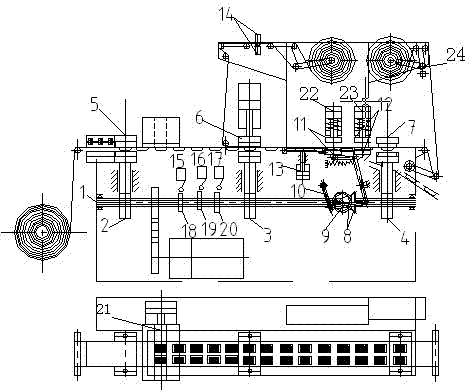

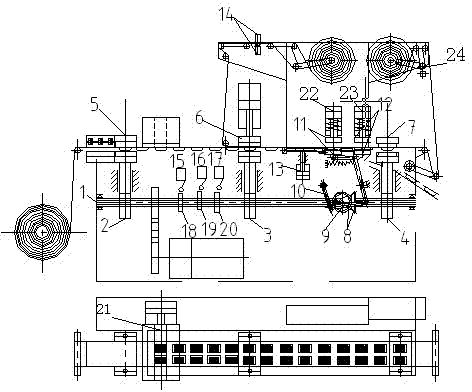

[0014] In the present invention, the power-on button is activated, the speed regulating motor rotates at a set rate, and drives the cam on the spline shaft 1 through the speed reducer and the chain drive. Switch 17, control the pneumatic solenoid valve through PLC to send a letter to turn on the air source, the tuyere on the blow mold is filled with air, and the blister molding of the lower PVC sealing tape is carried out. The drill bit entering the bubble shell is heat-sealed; the cam 4 closes the punching and shearing die 7, and punching and blanking the two-plate drill bit entering the station;

[0015] When the cam 2 continues to turn to the descending stroke, the blow mold 5 opens and closes, while the cam 3 opens and closes the heat sealing mold 6, and the cam 4 opens and closes the punching and shearing die 7; at this time, the cam 18 on the spline shaft 1 presses down the stroke Switch 15, send a letter to the PLC to control the moving cylinder 22, tighten the heat-sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com