Polypropylene composite material incombustible for 850 DEG C glowing filament and production method thereof

A composite material, a technology of burning polypropylene, applied in the field of plastic flame retardant, can solve the problems of burning, can not meet the flame retardant requirements of glow wire, etc., achieve the effect of avoiding burning, facilitating large-scale popularization and use, and strong solid phase barrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

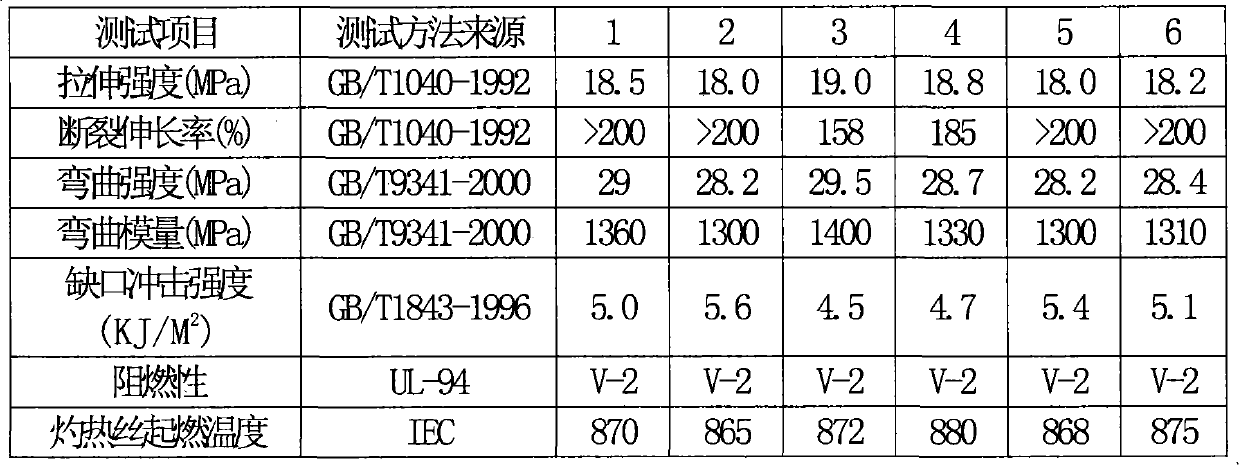

Examples

Embodiment 1

[0013] The ingredients by weight consist of:

[0014] Polypropylene 100Kg, ammonium polyphosphate 23.5Kg, microencapsulated tris-(2,3-dibromopropyl)isocyanurate 11.75Kg, melamine 11.75Kg;

[0015] After weighing the compound flame retardant and polypropylene by weight, put it into a high-speed mixer at a speed of 650 rpm and a maximum stirring line speed of 20 m / s, mix for 5 minutes, and then extrude in a twin-screw extruder granulation, and the extrusion temperature was 180-185°C to obtain sample 1.

Embodiment 2

[0017] The ingredients by weight consist of:

[0018] Polypropylene 100Kg, ammonium polyphosphate 22.5Kg, microencapsulated tris-(2,3-dibromopropyl)isocyanurate 9Kg, melamine 13.5Kg;

[0019] After the compound flame retardant and polypropylene are weighed by weight, put them into a high-speed mixer at a speed of 750 rpm and the maximum stirring line speed 20 Under the condition of m / s, mix for 7 minutes, and then extrude and granulate in a twin-screw extruder at an extrusion temperature of 183-190°C to prepare sample 2.

Embodiment 3

[0021] The ingredients by weight consist of:

[0022] Polypropylene 100Kg, ammonium polyphosphate 24Kg, microencapsulated tris-(2,3-dibromopropyl)isocyanurate 14.4Kg, melamine 9.6Kg;

[0023] After the compound flame retardant and polypropylene are weighed by weight, put them into a high-speed mixer at a speed of 1200 Turn / min, maximum stirring line speed 15 Under the condition of m / s, mix for 7 minutes, and then extrude and granulate in a twin-screw extruder at an extrusion temperature of 185-190°C to prepare sample 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com