A boiler decoking agent

A decoking agent and boiler technology, applied in the chemical field, can solve the problems of reducing coal ash, toxicity, shortening the service life of boilers, etc., and achieve the effects of prolonging service life, promoting combustion and reducing coking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

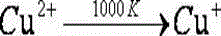

Method used

Image

Examples

Embodiment 1

[0020] The components and their weight percentages in this embodiment are: 50% aluminum nitrate, 30% borax, 15% copper nitrate, and 5% ammonium nitrate. The above raw materials are respectively fully ground to a particle size of 100 mesh to obtain the decoking agent product.

Embodiment 2

[0022] The components and their weight percentages in this embodiment are: 47 aluminum nitrate, 31 borax, 16 copper nitrate, and 6 ammonium nitrate. The above-mentioned raw materials are respectively fully ground to a particle size of 110 mesh to obtain the decoking agent product.

Embodiment 3

[0024] In this embodiment, each component and its weight percentage are: aluminum nitrate 45, borax 32, copper nitrate 16, ammonium nitrate 7. The above-mentioned raw materials are respectively fully ground to a particle size of 120 mesh to obtain the decoking agent product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap