Device for moulding and forming drilled hole wall

A technology for shaping and forming the hole wall, which is applied in earthwork drilling, wellbore/well components, sealing/isolation, etc. It can solve the problems of increased drilling cost, easy falling off and accidents in the hole, etc., and achieves follow-up drilling The effect of small operation impact, easy promotion and application, and reduced operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

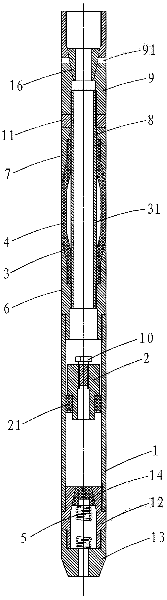

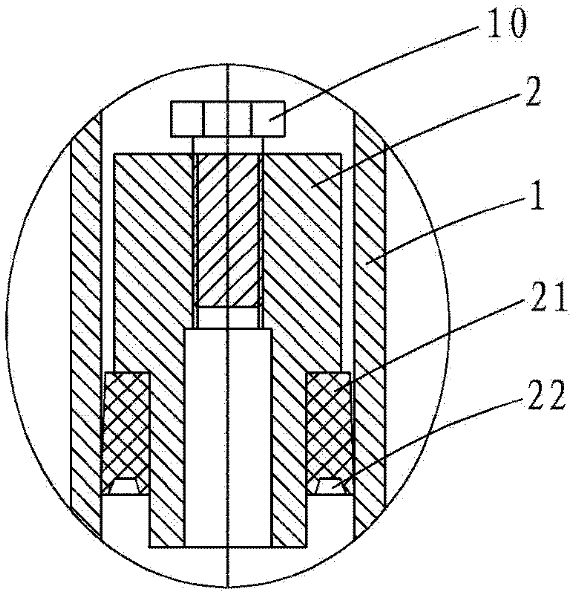

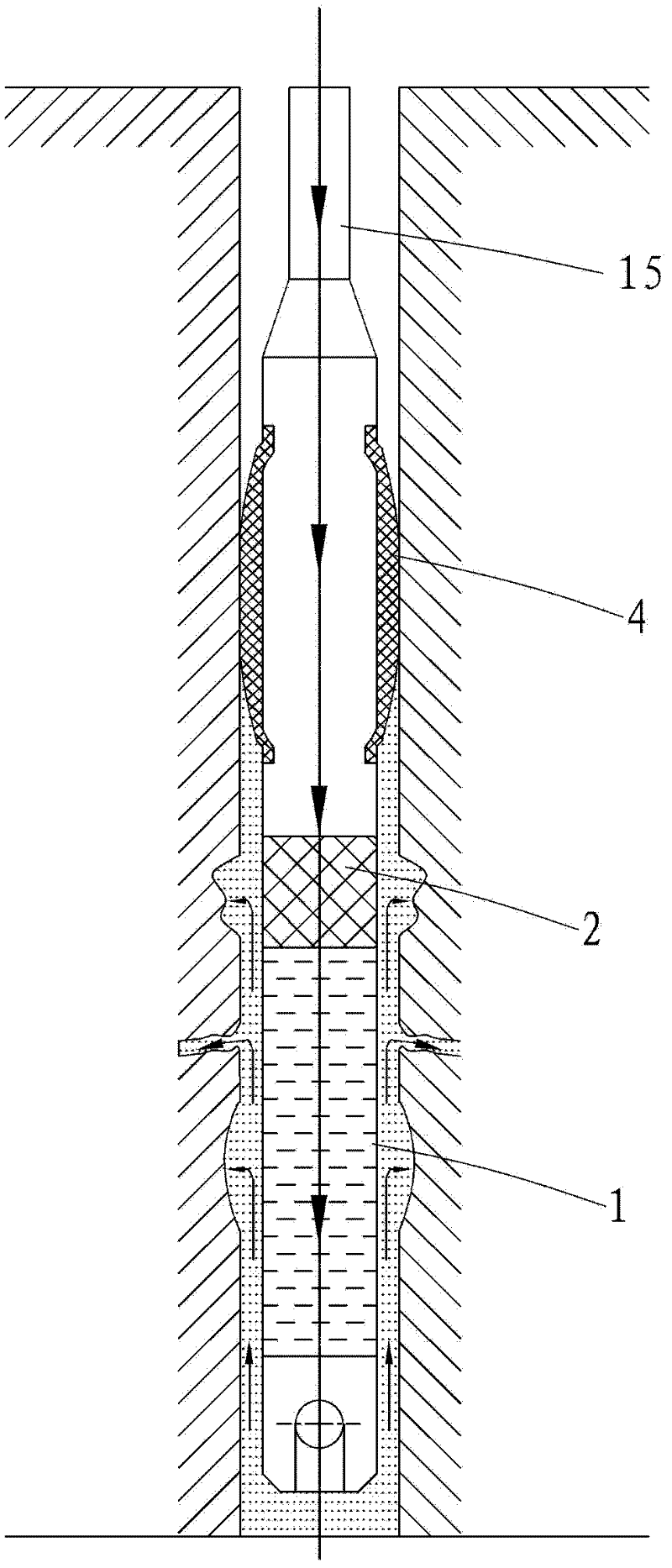

[0020] Example: see figure 1 , 2 , the drilling hole wall shaping device of the present embodiment includes:

[0021] The grout chamber 1 at the lower end, the lower end of the grout chamber 1 is threadedly connected with a hollow lower joint 12, and the lower end of the lower joint is threadedly connected with a hollow pilot joint 13, and the upper part of the inner cavity of the lower joint is provided with a round hole communicating with the inner chamber of the serous liquid chamber. A frustum-shaped passage, and a frustum-shaped lower piston 14 capable of blocking the frusto-conical passage is provided in the inner cavity of the lower joint. A spring 5 is also arranged in the inner cavity of the lower joint. The upper and lower ends of the spring 5 are respectively lowered by the lower piston 14 and the guide joint 13. For the spring seat. A piston seat 2 is arranged on the upper part of the inner cavity of the slurry chamber 1, a piston body 21 is sleeved on the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com