Method for measuring fluidization parameter of gas-solid fluidized bed

A fluidized bed and parameter technology, applied in fluid velocity measurement, measurement device, velocity/acceleration/impact measurement, etc., to achieve the effect of high detection accuracy and simple detection device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Example 1 Detection of particle cycle time

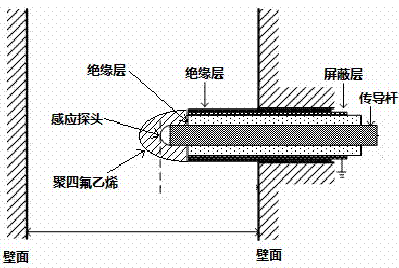

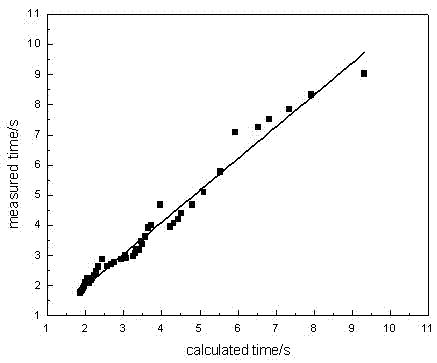

[0047] The method and device described in the present invention are used to measure the circulation time of particles in a gas-solid fluidized bed. The fluidized bed used in the experiment was Φ 150 mm plexiglass bed; the distribution plate adopts a porous iron plate with a hole diameter of 2mm, and the opening rate is 2.6%, and the distribution plate is kept well grounded during the experiment; the fluidized medium is dry nitrogen; the material is linear low-density polyethylene particles , whose melt index and density are 2.0 g·10min, respectively -1 and 920 kg·m -3 , the relative dielectric constant is 2.3, and the average particle size is 0.393 mm. Inductive electrostatic sensors such as figure 1 As shown, it protrudes 5mm from the side wall into the fluidized bed reactor. 8 different heights (30mm, 105mm, 185mm, 265mm, 345mm, 425mm, 505mm, 585mm) and 6 superficial air velocities (0.12m / s, 0.24m / s, 0.30m / s, 0.36m / ...

Embodiment 2

[0053] Example 2 Detection of flakes / blocks

[0054] The experimental device and experimental method are the same as in Example 1. The superficial gas velocity is 0.30 m / s -1 . The volume is 21.9, 40.5, 90, 178.5 cm 3 The 4 knots were placed into the fluidized bed from above the fluidized bed, and the electrostatic signals were collected at three heights of 30mm, 265mm, and 425mm, respectively, with a sampling frequency of 10000Hz and a sampling time of 100s. The electrostatic signal is processed by hardware filtering and software filtering to remove high-frequency noise above 200Hz.

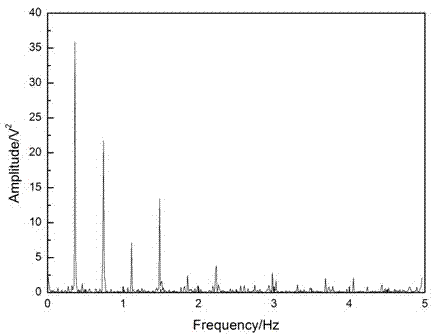

[0055] Method 1: Detect patches / blocks based on the shift of the fundamental modal frequency. The HHT transformation is performed on the electrostatic signal, and the frequency of the fundamental mode is taken as the characteristic parameter. Taking the electrostatic signal measured at a height of 30mm as an example for analysis, the experimental results are as follows Figure 4 As shown, ...

Embodiment 3

[0060] Example 3 Detection of Particle Concentration

[0061] The experimental device and experimental method are the same as in Example 1. The electrostatic signal is processed by hardware filtering and software filtering to remove high-frequency noise above 30Hz. By adjusting the superficial gas velocity, the porosity in the fluidized bed is changed, and then the particle concentration is changed, and the particle concentration is calibrated with a laser concentration detector. At a height of 30mm, collect the electrostatic signals at 6 superficial gas velocities (0.12m / s, 0.24m / s, 0.30m / s, 0.36m / s, 0.42m / s, 0.48m / s). The frequency is 1Hz, and the sampling time is 600s. As the superficial gas velocity increases, the particle concentration decreases. The average value of the electrostatic signal, the amplitude of the fundamental frequency of the electrostatic signal, and the energy of the fundamental mode of the electrostatic signal after HHT transformation are taken as pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative permittivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com