Porous graphite electrode for lead-acid battery

A lead-acid battery, porous graphite technology, applied in lead-acid battery electrodes, electrode carriers/current collectors, etc., can solve the problems affecting battery performance and life, active material shedding, large pollution, etc., to improve weight specific energy, production The effect of cost reduction and lead pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with drawings and embodiments.

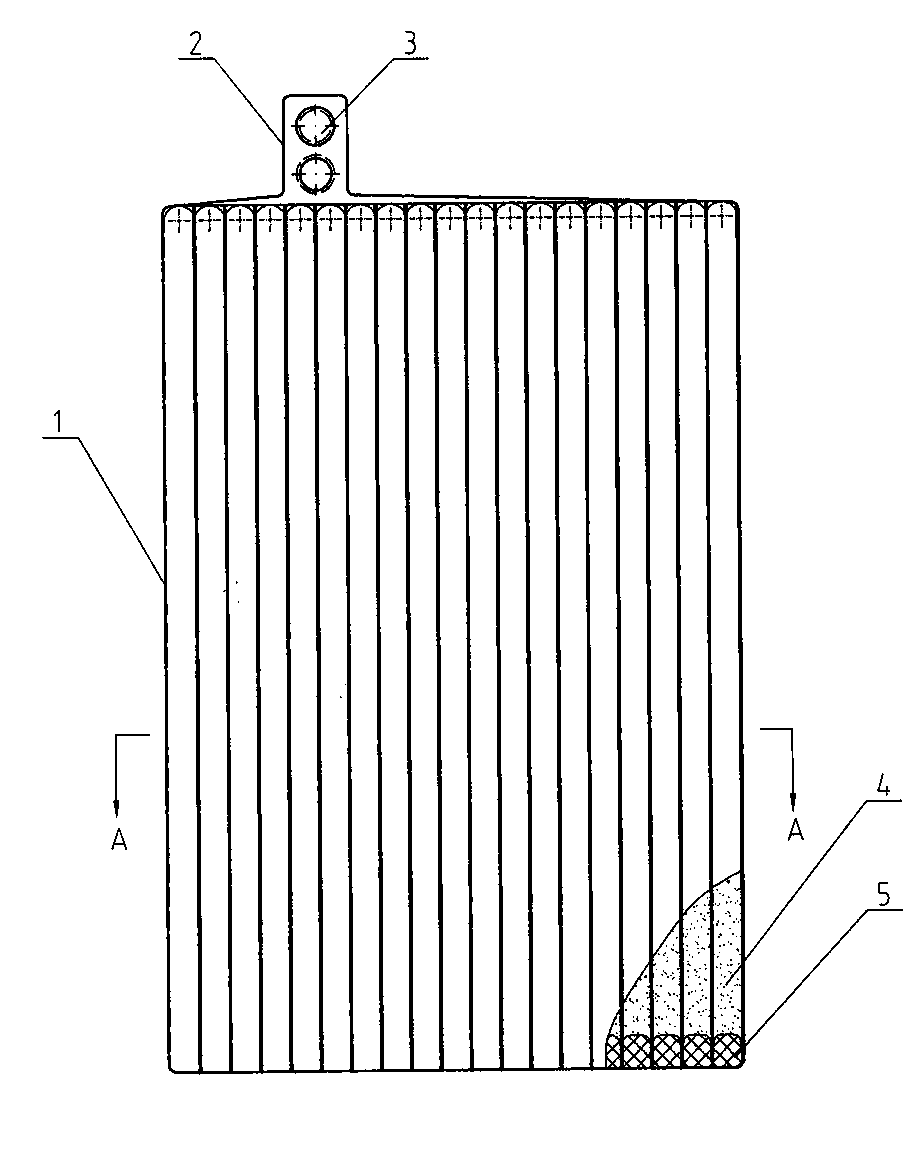

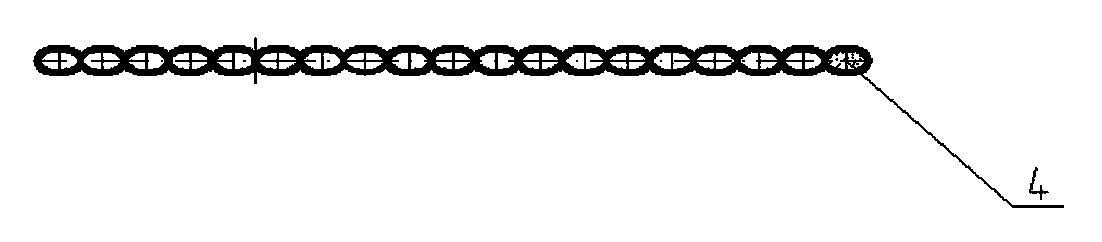

[0011] Referring to the accompanying drawings, the porous graphite electrode of the lead-acid battery is mainly composed of a pole plate 1, an active material 4 and a pole ear 2. The pole plate 1 is a porous graphite material, which is a tubular graphite structure connected by a plurality of parallel graphite tubes. The active material 4 is filled in the graphite tube. In this example, the wall thickness of the graphite tube is 0.8 mm, the porosity of the porous graphite is 50%, and the resistivity is less than 60 μΩ·cm. There are two connecting holes 3 on the lug 2 on the top of the pole plate, both of which are tapered holes, and the taper directions are opposite. The graphite tube opening at the bottom of the pole plate is provided with a PP plastic plug 5 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com