Multi-rotor-wing automatic positioning detector used for transmission line

An automatic positioning and transmission line technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of unsafe manual operation, complicated obstacle crossing process, low efficiency of manual line inspection, etc. The effect of ensuring safe and reliable operation and saving line inspection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

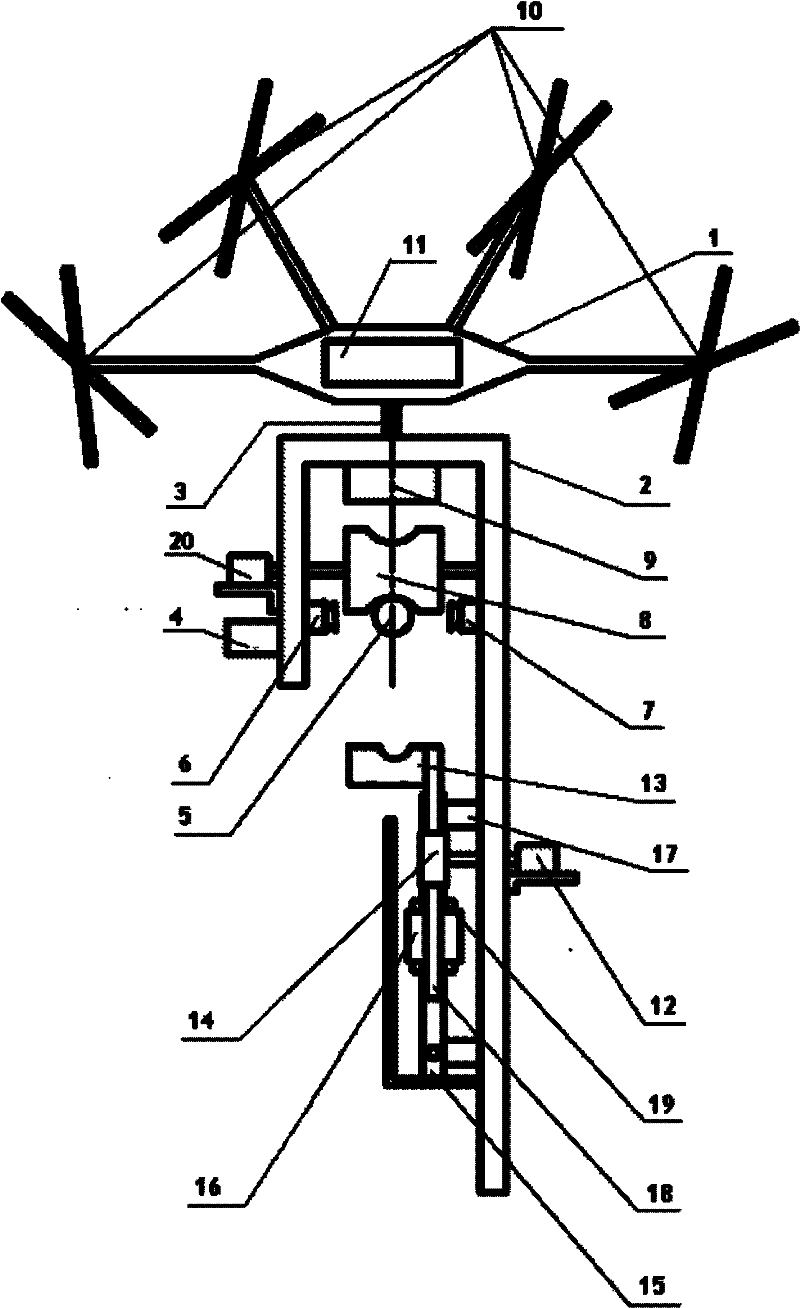

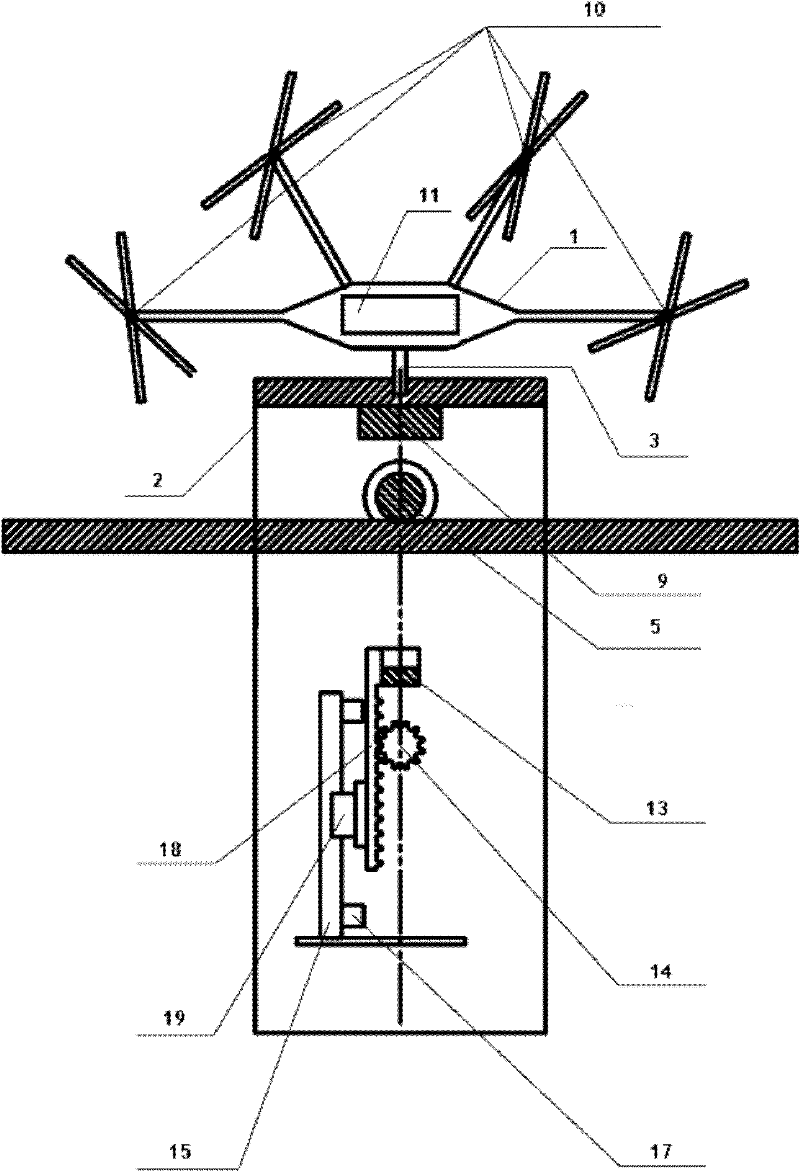

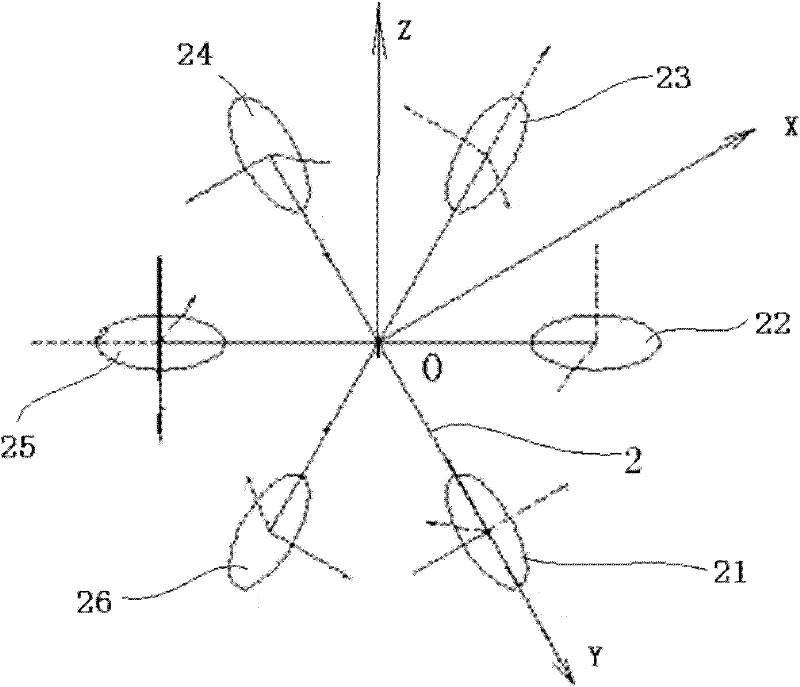

[0065] like Image 6 As shown, the body of the full-drive six-rotor micro air vehicle is provided with six connecting rods, which are evenly distributed around the body, and the outer ends of the six connecting rods are respectively connected to No. 1, No. 2, ..., No. , 26. Each rotor can be driven by a motor or an oil engine. The x and y axes of the aircraft body coordinate system are located in the plane where the six connecting rods are located and are perpendicular to each other. The z axis passes through the center of mass of the aircraft and is perpendicular to the plane where the six connecting rods are located. flat. The rotation planes of the six rotors form six inclinations with the xoy plane of the body coordinate system, and the rotation planes of each rotor are equal to the rotation planes of the third rotor separated by two rotors; the rotation planes of each rotor are the same as the adjacent rotors The inclination angle between the plane of rotation and the xo...

Embodiment 2

[0093] like Figure 7 As shown, the body of the underactuated six-rotor MAV is provided with three connecting rods, which are evenly distributed around the body. The outer end of each connecting rod is connected to the upper and lower rotors, and the first and second rotors 31 and 32 are connected to the same connecting rod No. 3 and No. 4 rotors 33 and 34 are connected to the outer ends of the same connecting rod, and No. 5 and No. 6 rotors 35 and 36 are connected to the outer ends of the same connecting rod. Each rotor can be driven by a motor or an oil engine.

[0094] The relationship between the virtual control quantity of the degree of freedom of the underactuated hexacopter MAV and the rotor speed is as follows:

[0095] U 21 U 22 U ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com