Laminate structure of stator iron core of motor

A technology of iron core lamination and motor stator, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit static parts, etc., can solve problems such as low production efficiency, non-concentric segmented arcs, and easy to produce errors, etc., to achieve Improve production efficiency, avoid end face magnetic flux leakage, and achieve high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

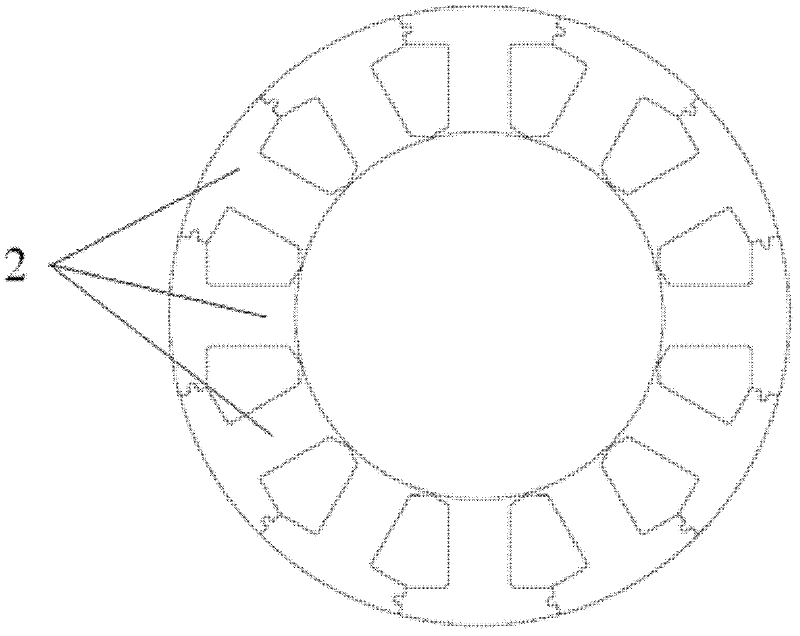

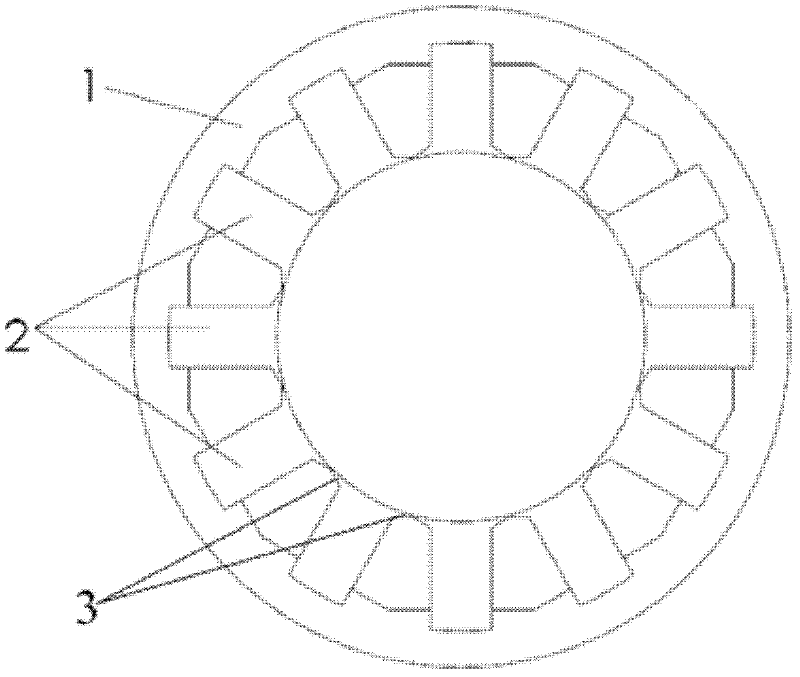

[0024] figure 1 It is a schematic diagram of a segmented stator core structure in the prior art, and the stator core is divided into several segmented stator cores. This segmented stator core splicing structure requires separate winding of each segment of the stator core, and the production efficiency is relatively low; moreover, there will be differences in the overlapping parts of each segment of the stator core. The inner and outer edges of the end face are uneven, which causes magnetic flux leakage on the end face and affects the efficiency of the motor. In addition, the lamination accuracy of the inner and outer circles of each stator core will be different, and after the segmented stator core is rounded, it is impossible to ensure the inner and outer edges of the stator core. The coaxiality of the circle cannot guarantee the cylindricity of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com