Dewatering and drying device

A drying, double-layer technology, applied in chemical instruments and methods, filtration separation, fixed filter element filters, etc., can solve the problems of complex processing technology, and achieve the effects of convenient processing, short compression time, and convenient and fast replacement operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

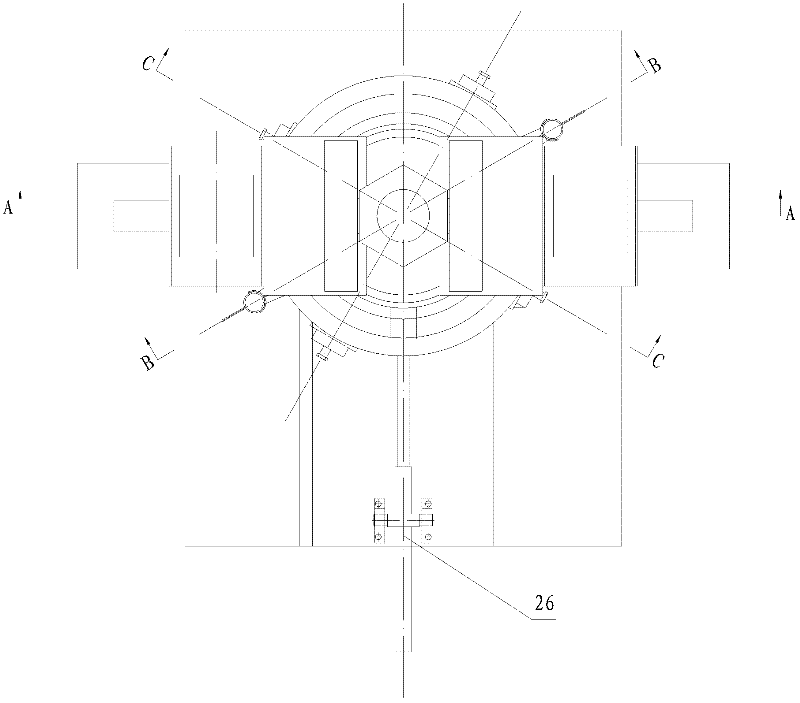

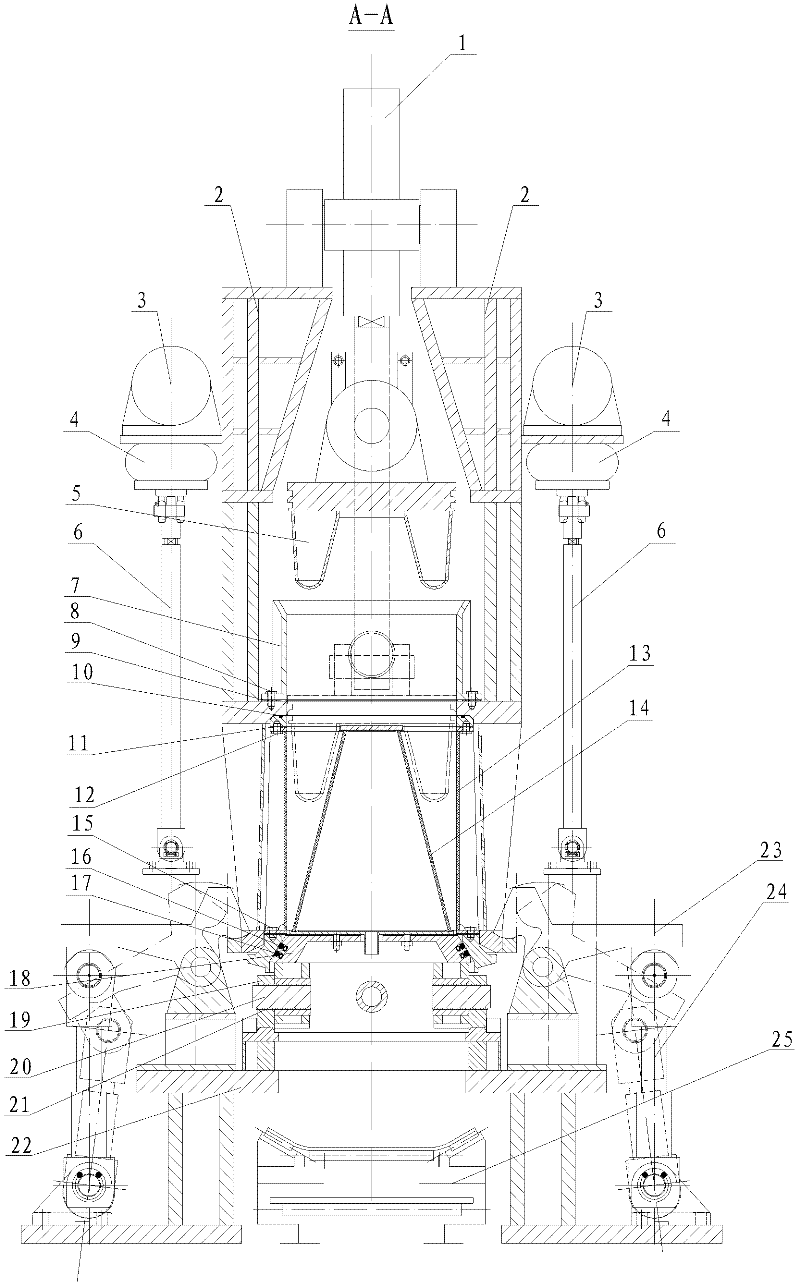

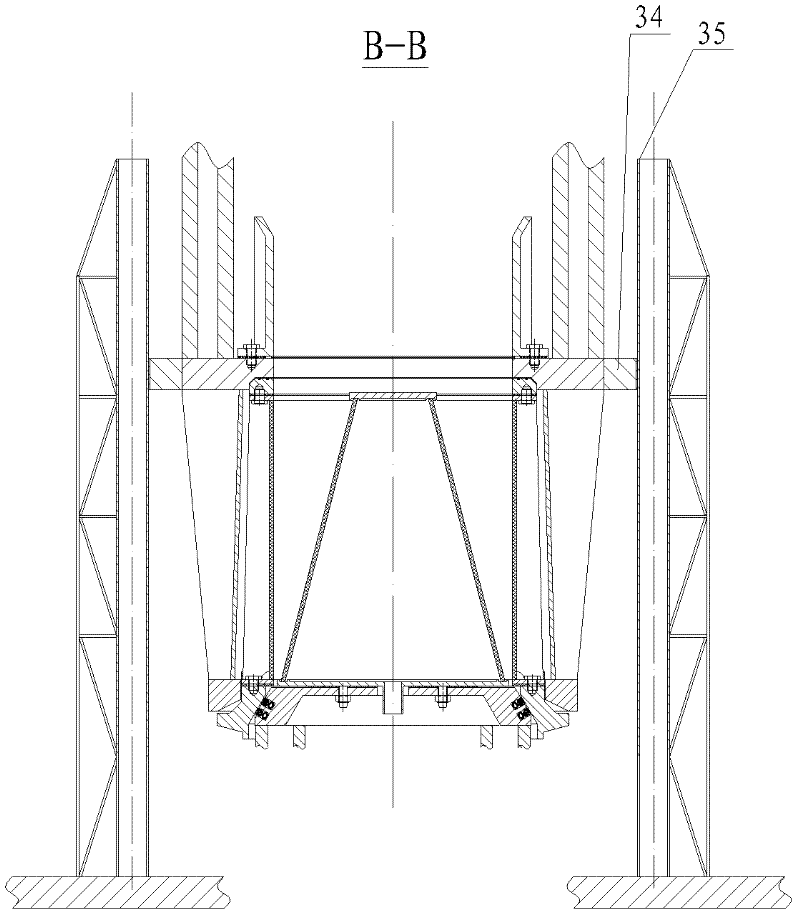

[0042] A dehydration and drying device, comprising a base, a pressure piston, a pressure-resistant sleeve, and a double-layer filter mechanism, the base is equipped with a double-layer filter, the double-layer filter is connected with a pressure-resistant sleeve, and the pressure-resistant sleeve There is a pressure piston on the opposite side, the pressure piston is equipped with a depressing tongue, and the pressure piston is connected with a push hydraulic cylinder. There are double-layer Y-shaped frameless polyurethane sealing rings between the pressure piston and the pressure-resistant sleeve. The pressure-resistant sleeve and the hydraulic cylinder of the pressure piston are installed on the support, and the support is installed on the base by a vibration eccentric motor, an air spring and a hydraulic cylinder. The pressure-resistant sleeve and the double-layer filter screen have a compression sealing lever, and the lever is connected with a swingable hydraulic cylinder....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com