Method and system for automatic thickness control over high-precision strip steel rolling under monitoring

An automatic thickness control, high-precision technology, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve the problems of inability to obtain accurate values, affecting the accuracy of monitoring AGC, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

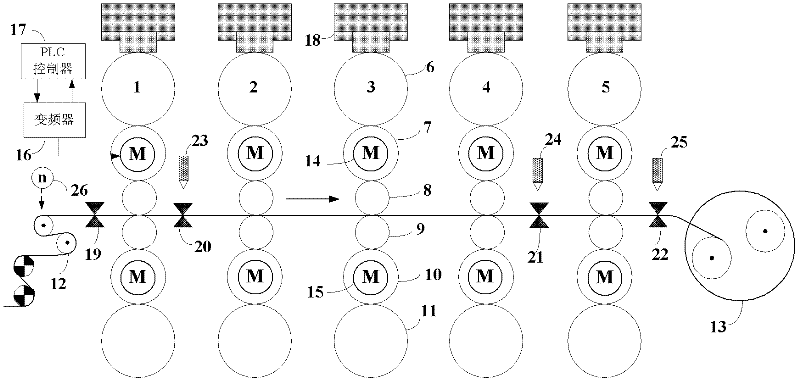

[0077]figure 1 It is a schematic diagram of a five-stand tandem cold rolling mill and its main detection components. The five stands of the five-stand tandem cold rolling mill are all six-high rolling mills. The numbers 1 to 5 above the stands represent stands 1 to 5, respectively. The rolling direction From left to right. Since the mechanical equipment of each stand is the same, take stand No. 3 as an example to illustrate the equipment composition of a five-stand continuous rolling mill: stand No. 3 consists of upper support roll 6, upper intermediate roll 7, upper work roll 8, It consists of a lower work roll 9, a lower intermediate roll 10, and a lower support roll 11. In addition, tension rollers 12 are installed at the entrance of the continuous rolling mill, and coilers 13 are installed at the exit; , the programmable logic controller (PLC) 17 sends the speed adjustment amount to the frequency converter, and the frequency converter adjusts the motor speed to make the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com