Vane compressor

A compressor and blade technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of reduced performance of the seal, poor sintering, core dislocation, etc., to prevent partial wear and sintering, improve reliability, improve The effect of core misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

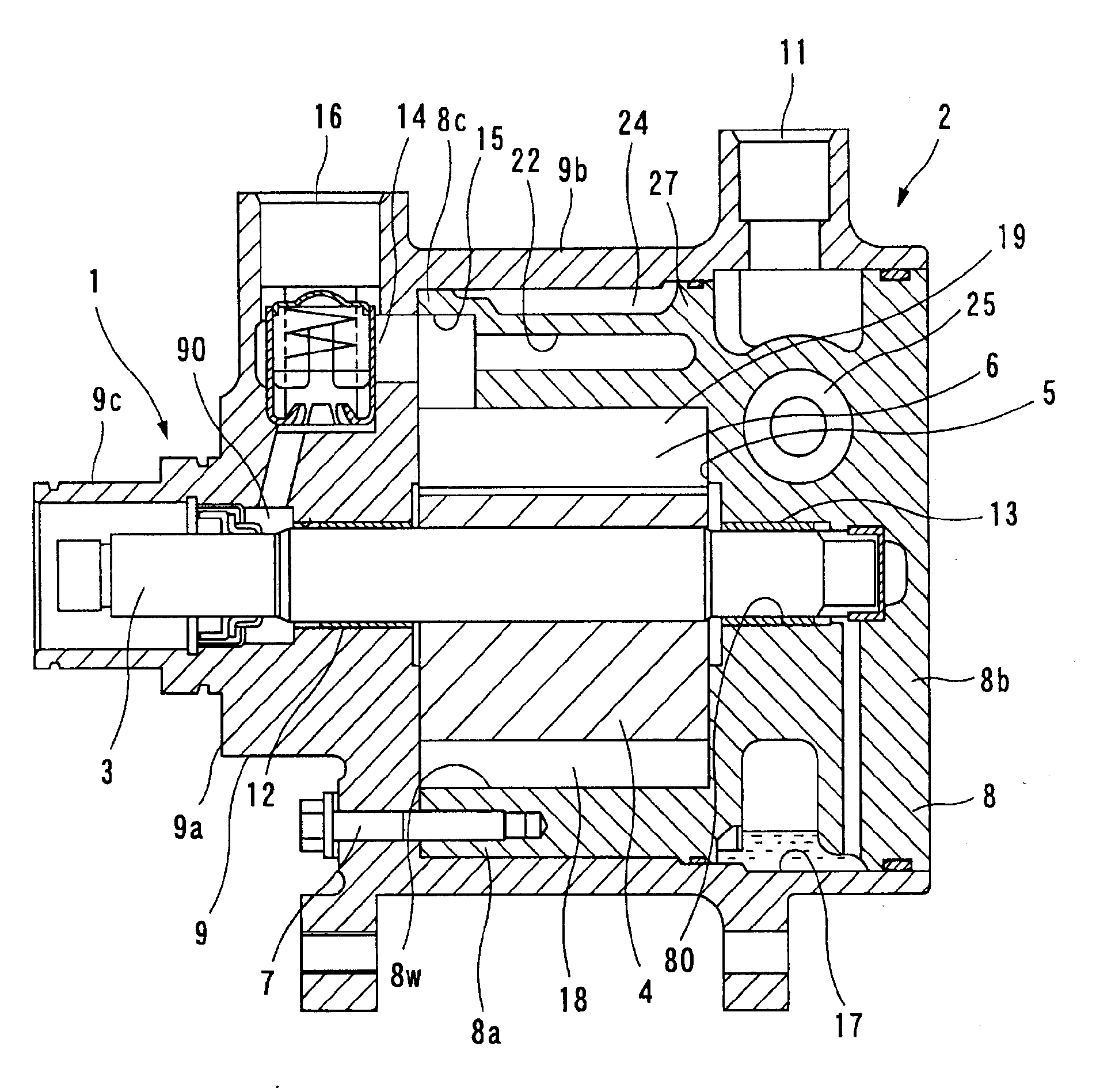

[0036] Hereinafter, the vane type compressor of the present invention will be described with reference to the drawings.

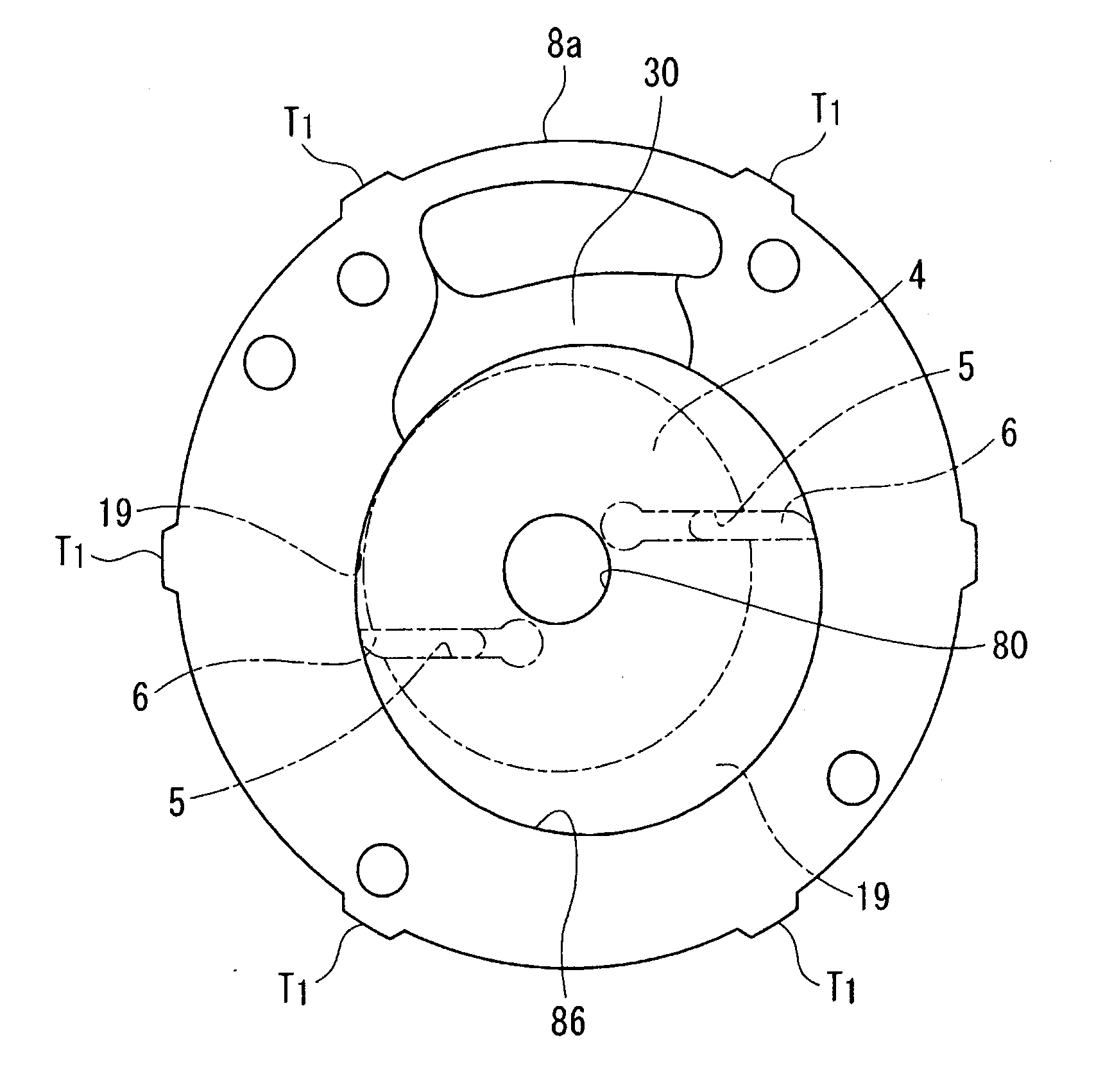

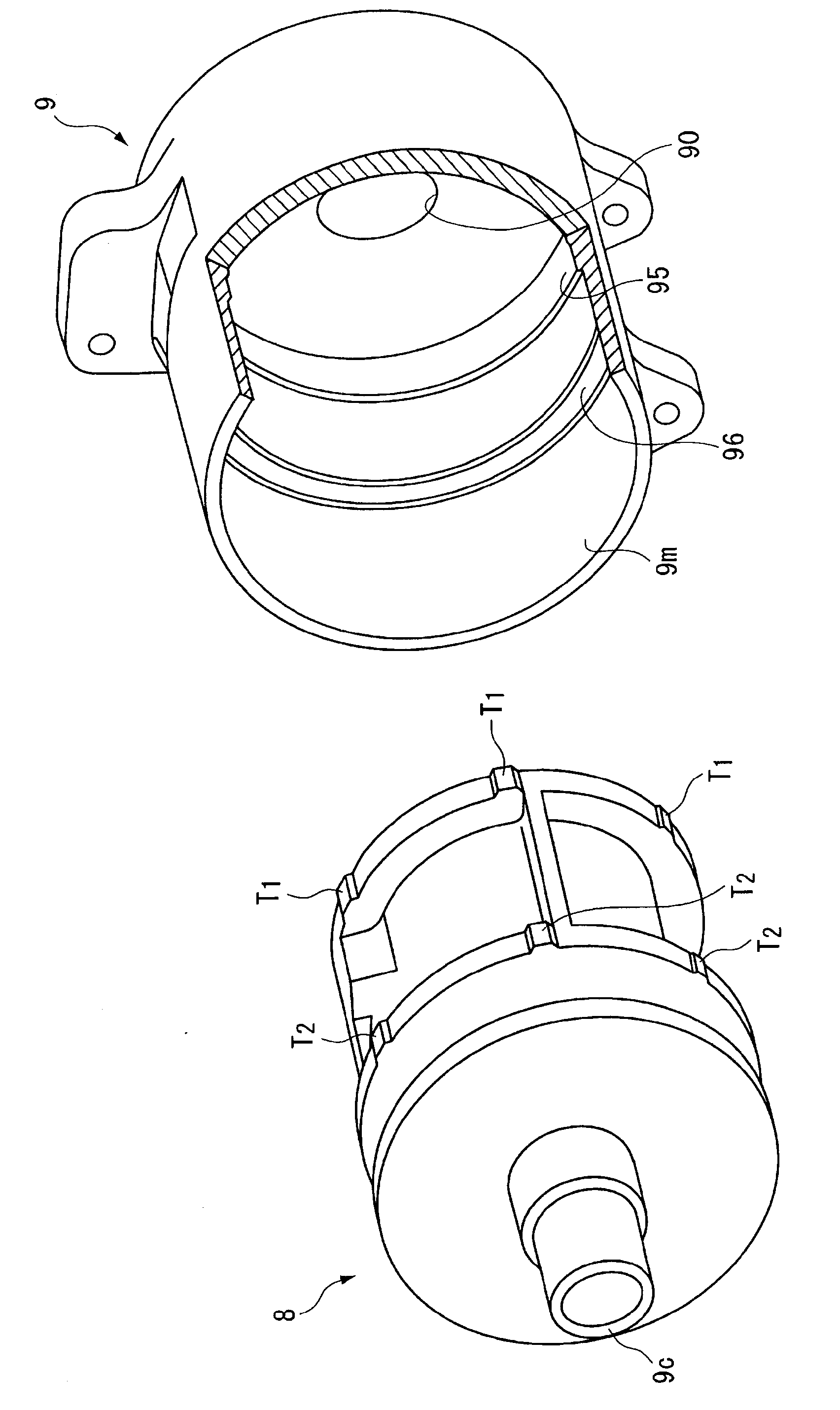

[0037] in figure 1 Indicates a vane-type compressor suitable for refrigeration cycles using a cooling medium as a working fluid. The vane type compressor 1 such as figure 1 as well as figure 2 As shown, there are a drive shaft 3, a rotor 4 fixed to the drive shaft 3 and capable of moving with the rotation of the drive shaft 3, a first housing member 8 that partitions a compression space 18 described later by the rotor 4, and a second In the case member 9, the first case member 8 and the second case member 9 constitute a case 2 that houses the drive shaft 3, the rotor 4, and the like.

[0038] The first housing member 8 includes: a cylinder forming portion 8a having a cylinder hole 86 for accommodating the rotor 4, and a cylinder forming portion 8a located on the rear side of the drive shaft 3 in the axial direction than the cylinder forming portion 8a and formi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com