Dew point corrosion resistant method for flue gas heat exchanger

A flue gas heat exchanger and pitting corrosion technology, which is applied in the direction of damage protection, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of limited effect and difficult to adjust and control the heat exchange tube wall, and achieve Large waste heat recovery effect, avoid dew point corrosion, large steam flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

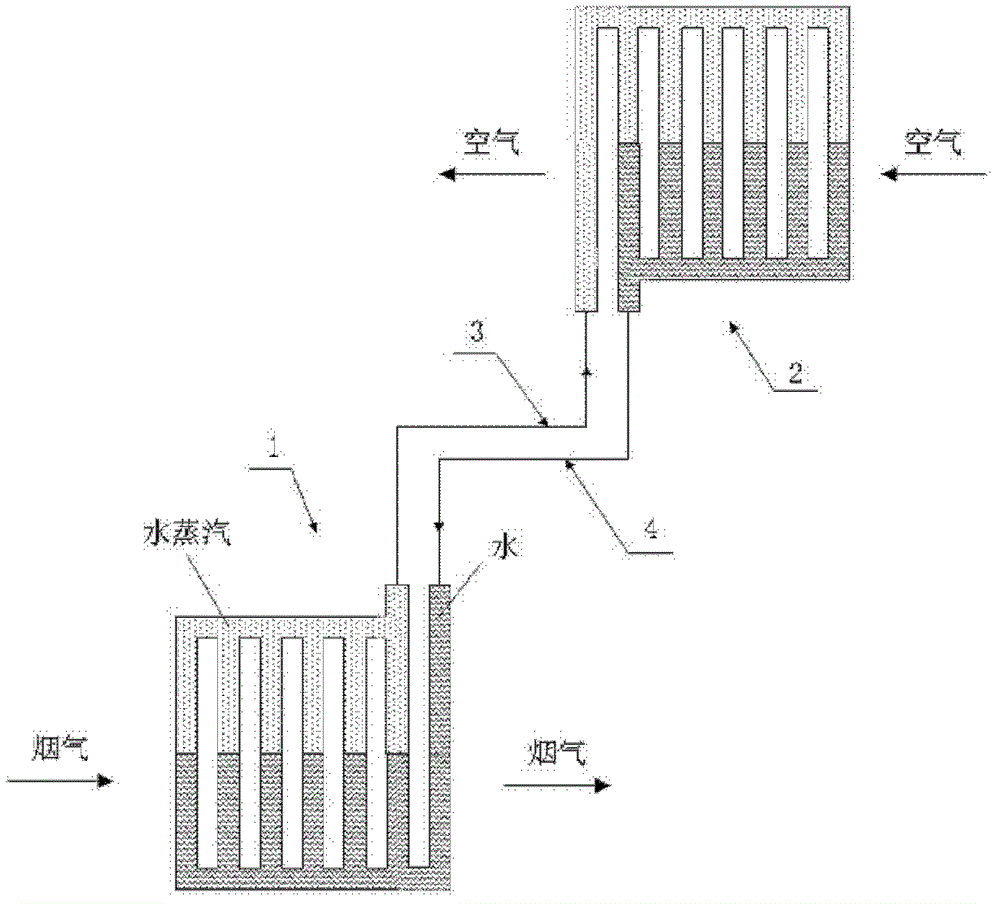

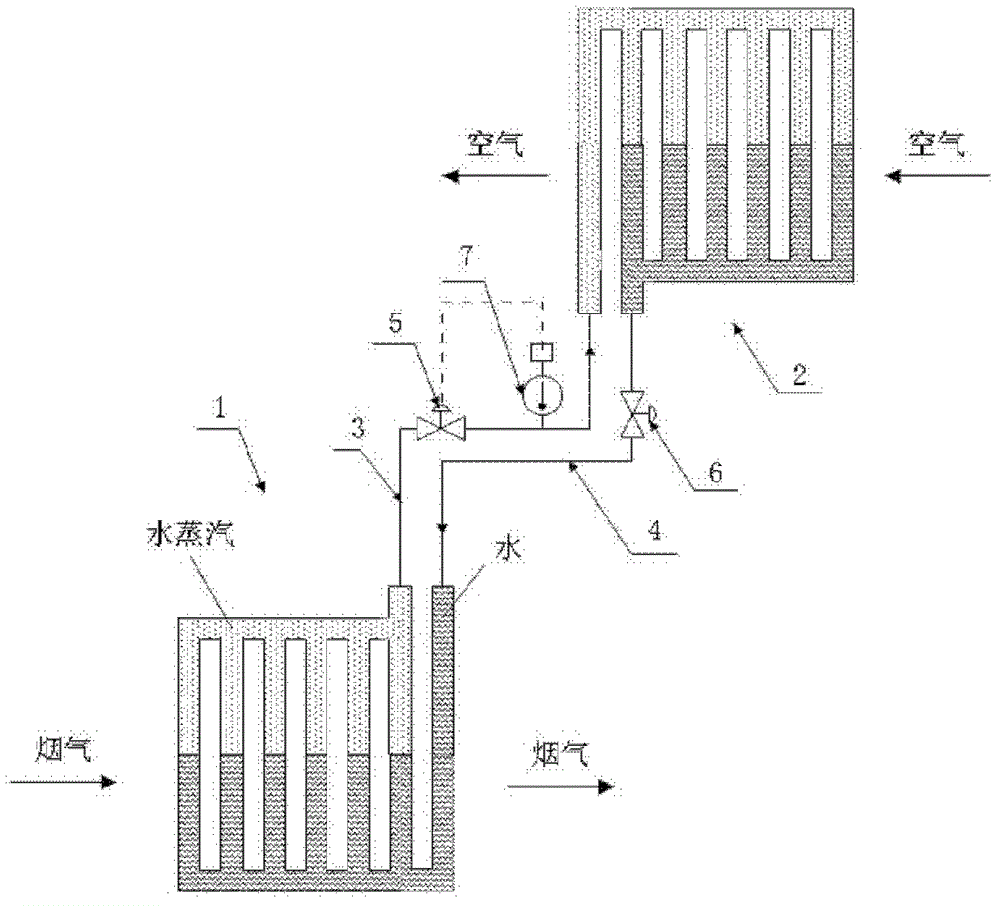

[0028] Such as figure 2 As shown, in the prior art (see figure 1 ) on the basis of the steam riser of the two-phase flow heat exchanger, a steam flow regulating valve 5 and a temperature measurement or temperature measurement and control device 7 are set so that the steam flow and pressure can be controlled manually or automatically. During manual control, the steam flow regulating valve 5 can be various regulating valves such as manual, pneumatic, hydraulic, electromagnetic, etc., and the device 7 can be a simple temperature measuring instrument. During automatic control, the steam flow regulating valve 5 is a pneumatic, hydraulic, electromagnetic and other regulating valves that can accept control signals, and the temperature measurement and control device 7 can be a single element with both temperature measurement and temperature control functions, or it can be a temperature measurement Combination of elements and temperature control elements.

[0029] When in the prefer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com