Flue gas recovery system of glass kiln heat preservation channel

A glass furnace and heat preservation channel technology, applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as low flue gas, improve heat exchange efficiency, improve overall life, and avoid dew point corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

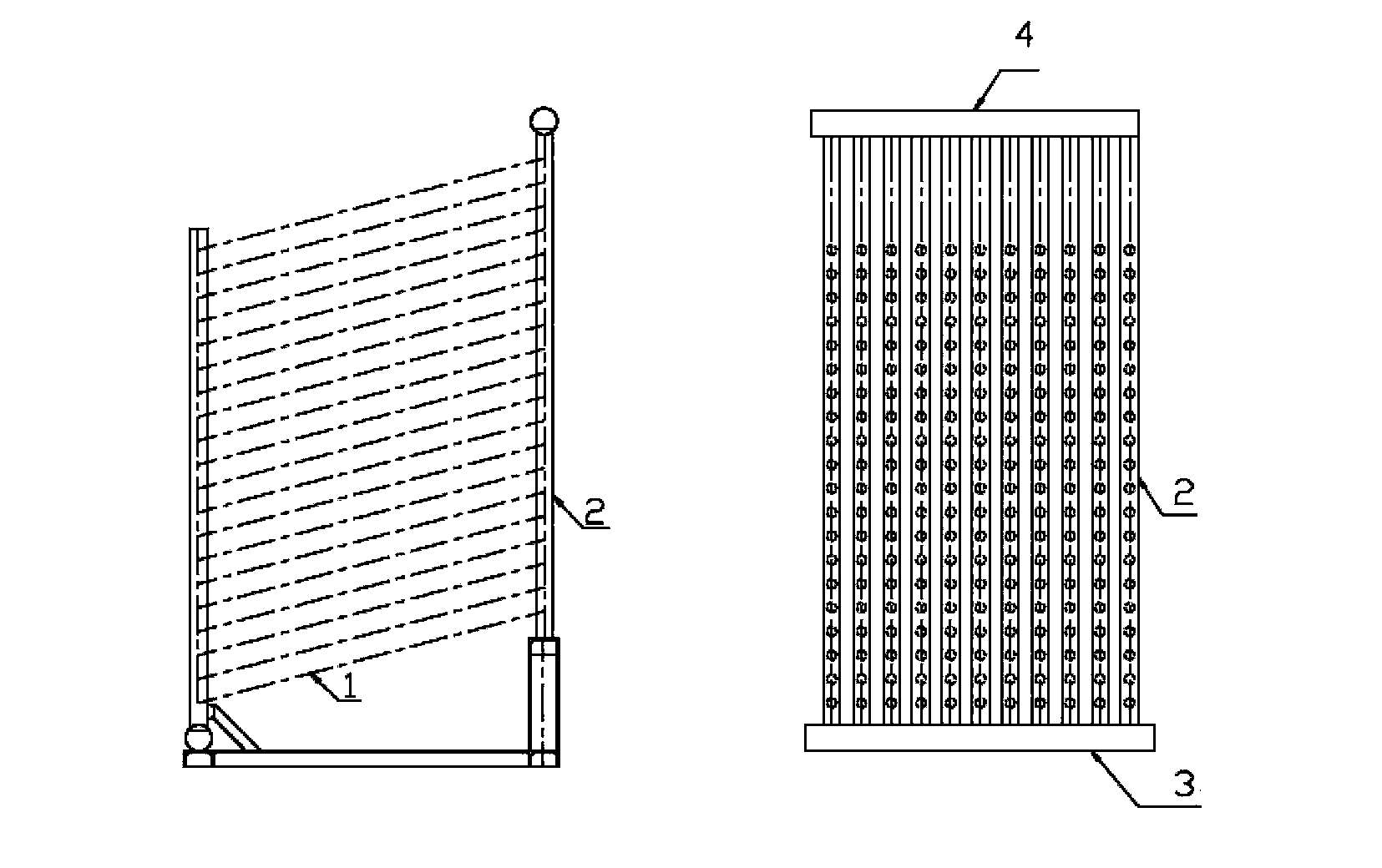

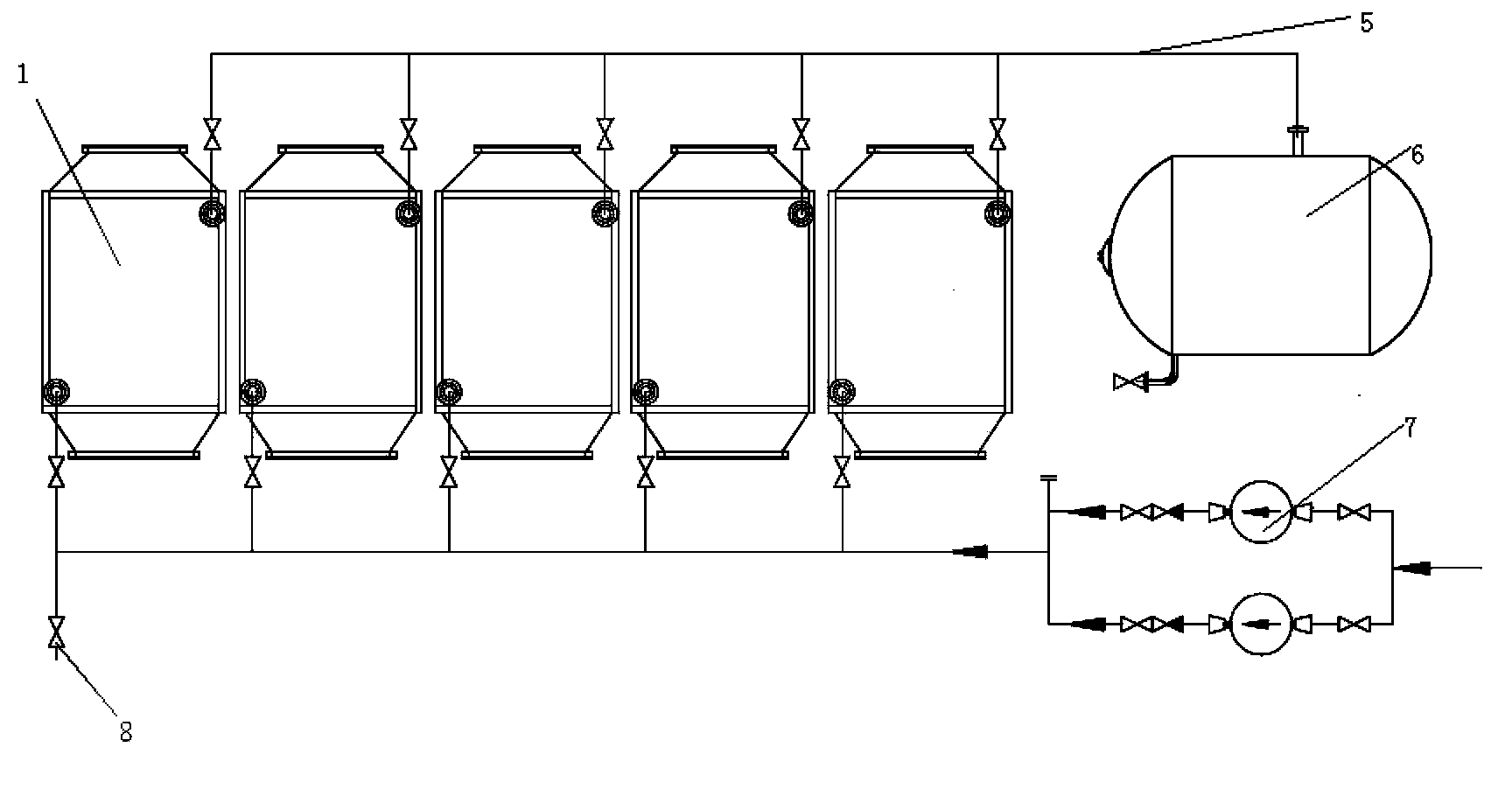

[0013] The flue gas recovery system of the heat preservation channel of the glass kiln provided by the present invention comprises: a group of heat exchangers, an air outlet pipe (5), a steam drum (6), a circulating water pump (7) and a blowdown valve (8), wherein: The heat exchanger, the air outlet pipe and the steam drum are connected sequentially; the heat exchanger includes multiple sets of parallel finned tubes (1), water pipes (2), water inlet pipes (3) and steam headers (4) Composition, the water inlet pipe, water union pipe, finned tube, and steam header are sequentially connected; the finned tube is filled with working medium and evacuated; the glass kiln heat preservation channel flue gas recovery The system also includes a water pump.

[0014] When working, the cold water enters into the joint pipe through the water inlet pipe under the action of the water pump, and then enters the finned tube for heating. The cold water is heated and vaporized and then rises into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com