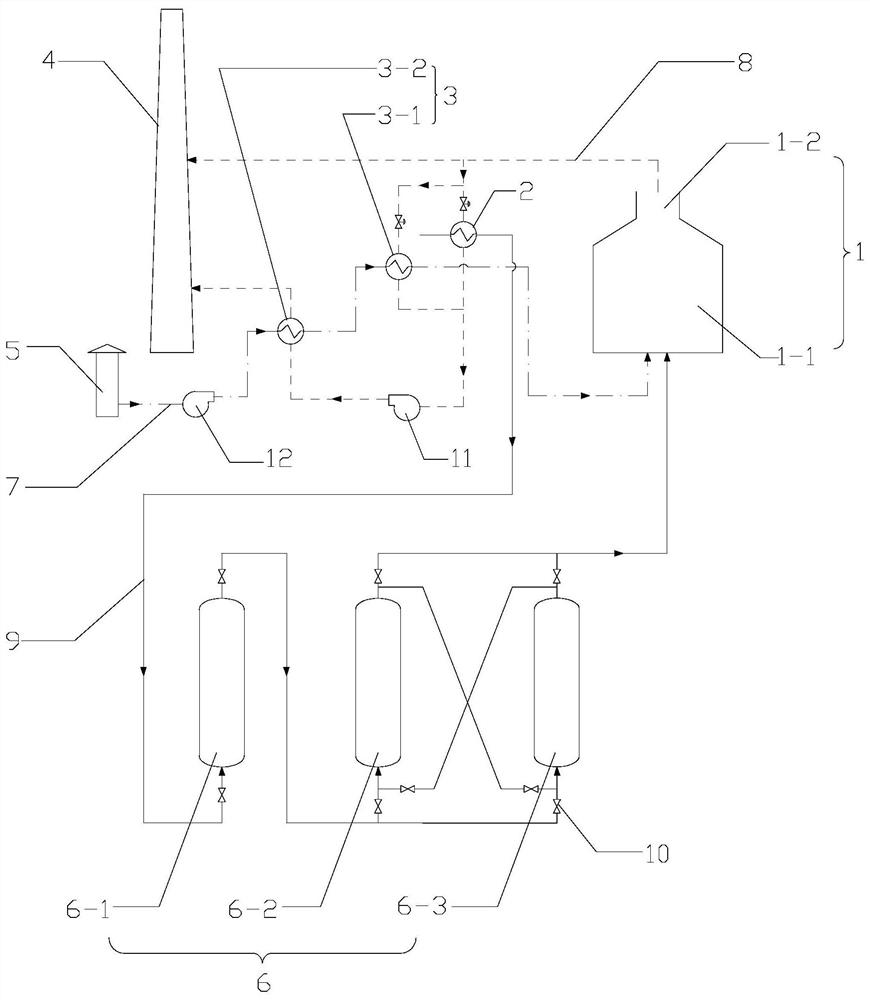

High-efficiency recovery system for low-temperature waste heat of xylene heating furnace

A low-temperature waste heat recovery system technology, applied in the field of petrochemical industry, can solve the problems of low recovery efficiency of low-temperature waste heat and limited flue gas discharge temperature, and achieve the effects of reducing operating energy consumption, avoiding dew point corrosion, and large surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

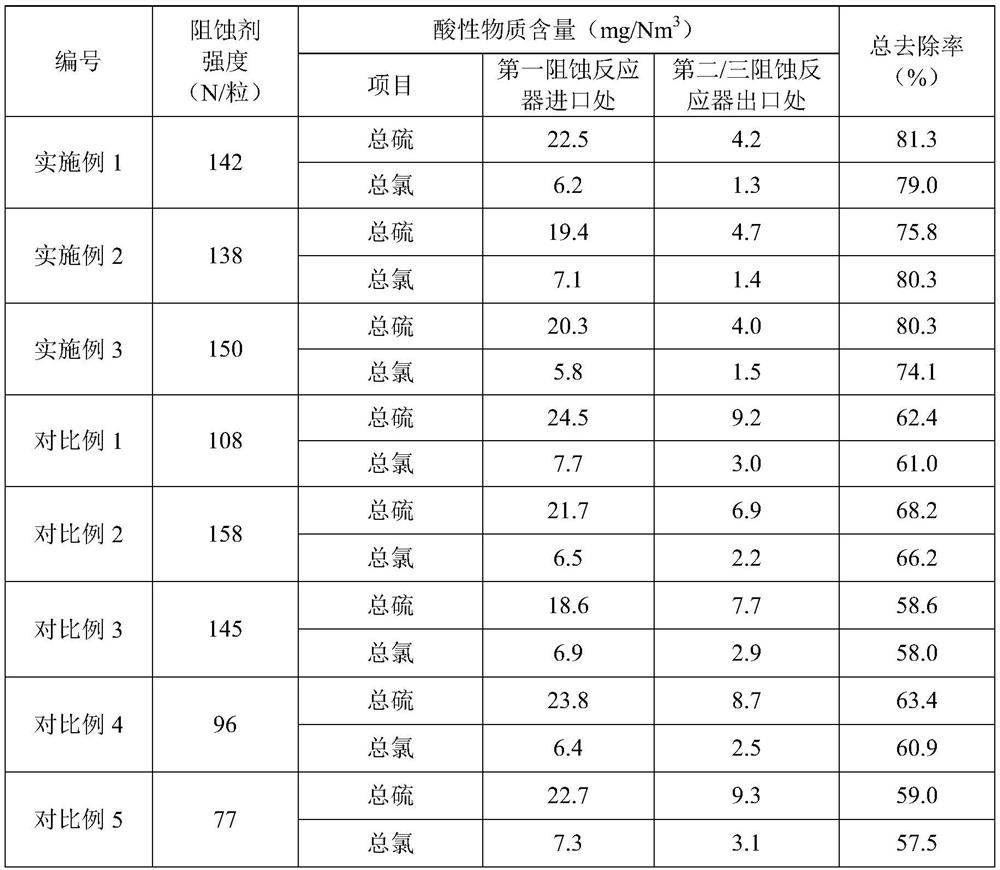

Embodiment 1

[0045] The intake rate of the fuel gas in Example 1 is 10t / h; the loading amount of the corrosion inhibitor in the first corrosion inhibition reactor is 22.5t, and the loading volume of the corrosion inhibitor in the second and the third corrosion inhibition reactor is 30t .

[0046] The preparation method of corrosion inhibitor is:

[0047] (1) Mix zeolite powder, KOH powder and pseudo-boehmite powder uniformly in a mass ratio of 50:7:12 to obtain powder;

[0048] (2) Turn on the granulator, adjust the rotating speed to 25rpm, add the powder into the granulator, and gradually add 25wt% nitric acid solution as a binding agent at the same time, and carry out rotational molding to obtain balls with a particle size of 4mm. The mass ratio of the addition of agent and the zeolite powder in the powder is 26:50;

[0049] (3) Place the pellets in an airtight container and age them for 36 hours;

[0050] (4) The corrosion inhibitor is obtained by activating the aged pellets at a hig...

Embodiment 2

[0052] The intake rate of fuel gas in Example 2 is 10t / h; the loading amount of corrosion inhibitor in the first corrosion inhibitor reactor is 22.5t, and the loading amount of corrosion inhibitor in the second and third corrosion inhibitor reactors is 30t .

[0053] The preparation method of corrosion inhibitor is:

[0054] (1) Mix zeolite powder, KOH powder and pseudo-boehmite powder uniformly in a mass ratio of 50:6:10 to obtain powder;

[0055] (2) Turn on the granulator, adjust the rotating speed to 25rpm, add the powder into the granulator, and gradually add 20wt% nitric acid solution as a binding agent at the same time, carry out rotational molding, and obtain a material ball with a particle diameter of 3mm, bonded The mass ratio of the addition of agent and the zeolite powder in the powder is 25:50;

[0056] (3) Place the pellets in an airtight container and age them for 24 hours;

[0057] (4) The corrosion inhibitor is obtained by activating the aged pellets at a h...

Embodiment 3

[0059] The intake rate of fuel gas in Example 3 is 10t / h; the loading amount of corrosion inhibitor in the first corrosion inhibitor reactor is 22.5t, and the loading amount of corrosion inhibitor in the second and third corrosion inhibitor reactors is 30t .

[0060] The preparation method of corrosion inhibitor is:

[0061] (1) Mix zeolite powder, KOH powder and pseudo-boehmite powder uniformly in a mass ratio of 50:8:15 to obtain powder;

[0062] (2) Turn on the granulator, adjust the rotating speed to 25rpm, add the powder into the granulator, and gradually add 30wt% nitric acid solution as a binding agent at the same time, carry out rotational molding, and obtain a material ball with a particle diameter of 5mm, bonded The mass ratio of the addition of agent and the zeolite powder in the powder is 27:50;

[0063] (3) Place the pellets in an airtight container and age them for 48 hours;

[0064] (4) The corrosion inhibitor was obtained by activating the aged pellets at a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com