Method for measuring temperature of melted tin during welding of battery film

A cell welding and measurement method technology, applied in the application of thermometers, thermometers, measuring devices, etc., can solve the problems of small thermal conductivity and inconsistent formation temperature of measuring alloy layers, and achieve the effect of reducing exploration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] A method for measuring the temperature of battery sheet welding melting tin, which involves drilling 2 to 3 through holes on the surface of the battery substrate, using a temperature sensor element, one end of which is embedded in a pre-processed through hole and fixed with a thermally conductive colloid Connect the temperature transmission device, and reflect the dynamic process of temperature change in the welding process through the output of temperature data in the temperature transmission device.

[0009] Methods for data analysis and quality problem characterization:

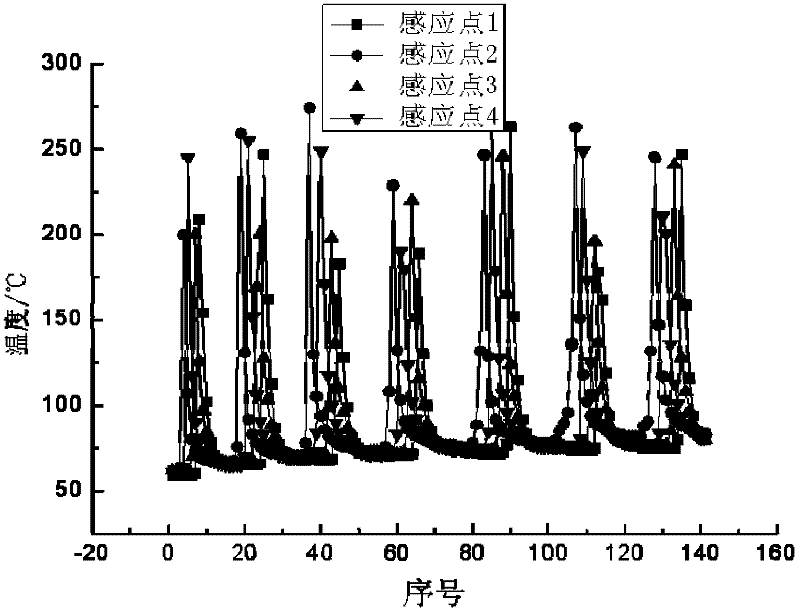

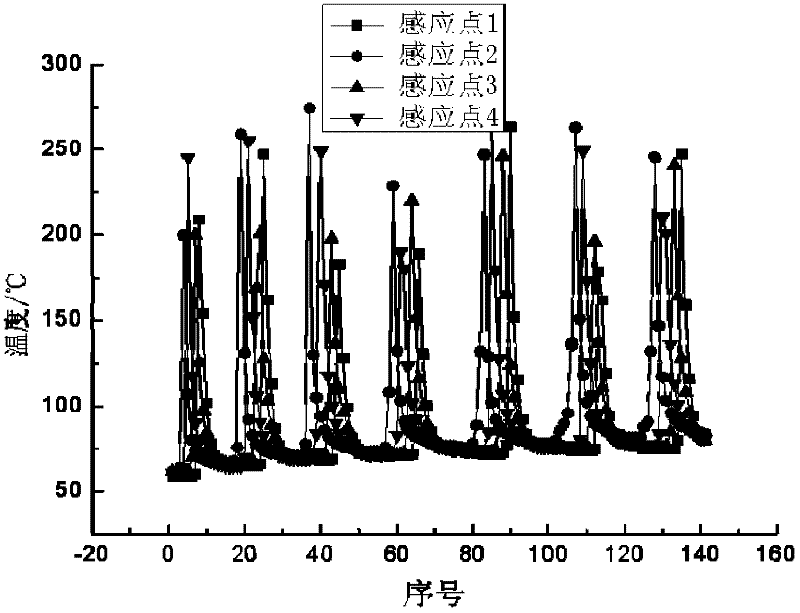

[0010] figure 1 It is the data output in the temperature variable speed device. It can be seen that the temperature of the soldering iron is gradually decreasing. When welding the first solder joint, the temperature has a downward trend, and the temperature downward trend is obvious during continuous welding. The data show that the tin-lead binary alloy The eutectic point is about 183°C. According ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com