Preparation method of lithium battery anode slurry

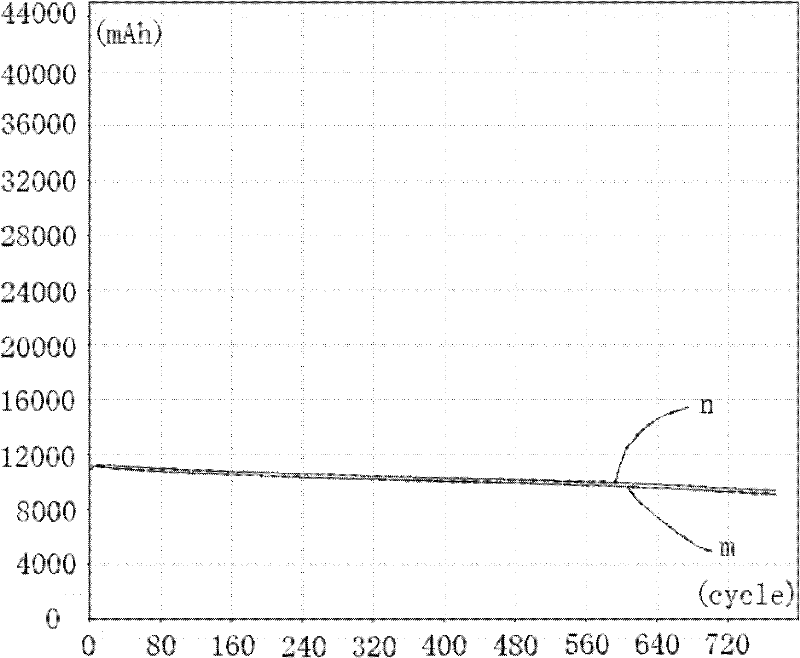

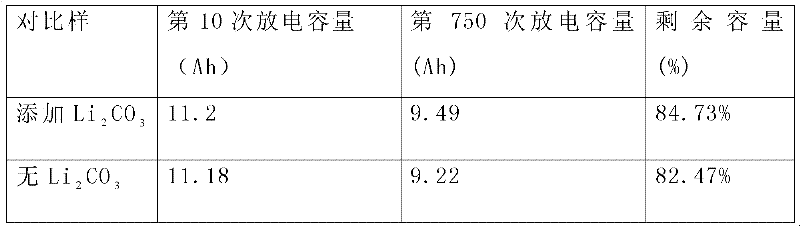

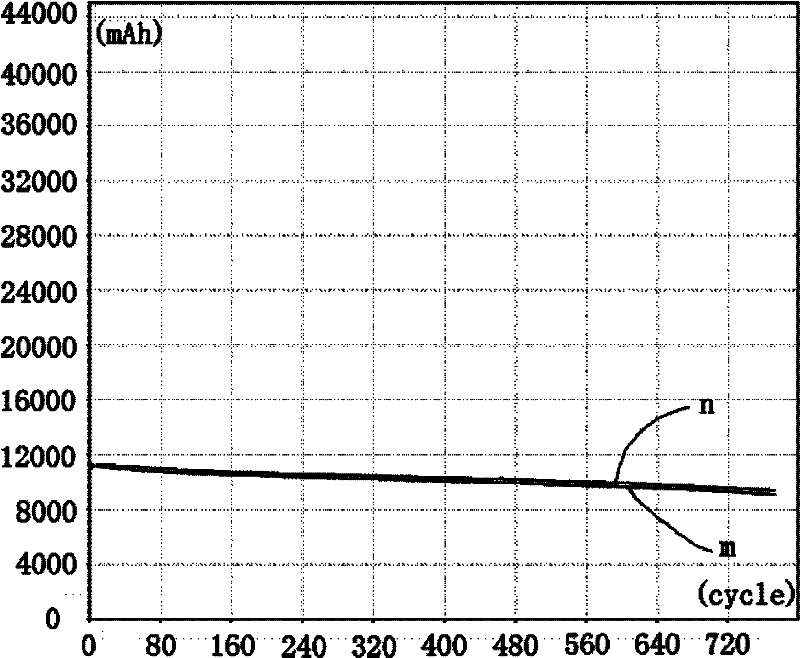

A positive electrode slurry and preparation method technology, applied to battery electrodes, circuits, electrical components, etc., can solve the problems of lower production efficiency, uniform mixing of difficult mixtures, increased energy consumption, etc., to achieve increased reversible capacity, shortened stirring time, Effect of cycle performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0017] Embodiment 1: The equipment adopts a 100L vacuum dispersion mixer.

[0018] Add raw materials for the first time: first add 35kgNMP, then add 2.608kgPVDF, the stirring speed of the first stage is 10HZ for revolution, 5HZ for rotation, and the stirring time is 15min. Scrape the dry PVDF powder and viscous matter into the mixer with a scraper; the stirring speed of the second stage is 30HZ for revolution and 30HZ for rotation, vacuumize during the second stirring process, and keep the air pressure in the mixer at -0.08~-0.1MPa , The second stirring time is 2h, the temperature is kept at 40-50°C during the stirring process, and finally stand still for more than 2h, so that the glue has no bubbles.

[0019] Add raw materials for the second time: add ks-15, sp, lithium manganate and Li to the prepared glue 2 CO 3 Mix the powder, and then start stirring. The stirring speed of the first stage is 5HZ for revolution, 5HZ for rotation, and the stirring time is 10min. Scrape it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com