Method for detecting initial magnetic field position of linear synchronous motor

A technology of motor position and detection method, applied in the direction of electronic commutator, etc., can solve the problems of electrical angle deviation, large calculation error, large software calculation amount, etc., to avoid a large number of calculations, improve detection accuracy and fast detection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

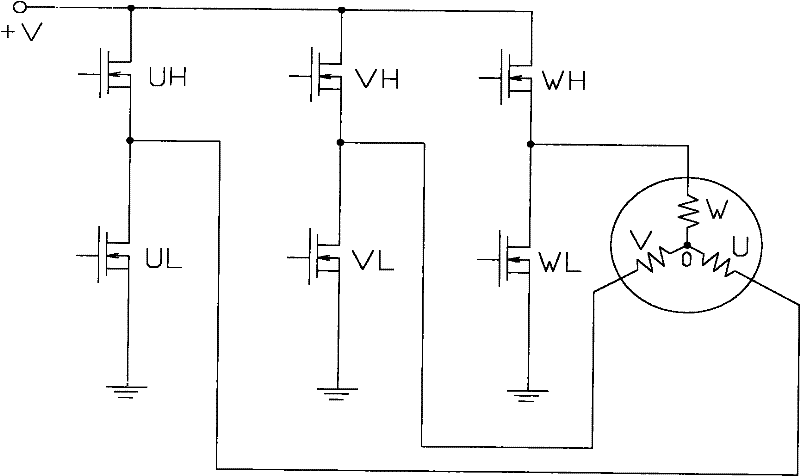

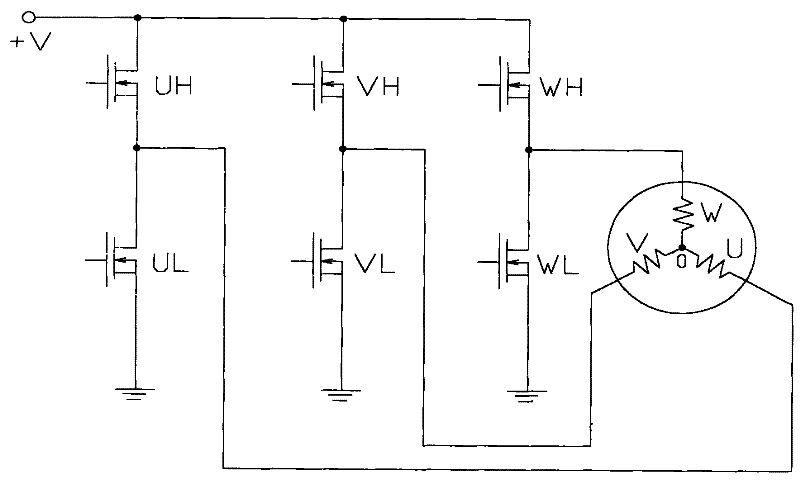

[0010] like figure 1 As shown, the method for detecting the initial magnetic field position of a linear synchronous motor of the present invention includes a motor controlled by a three-phase inverter of a servo controller and an incremental photoelectric encoder for detecting the position of the motor. The three-phase winding of the motor U , V and W are connected at one end, and the other ends of the three-phase windings U, V and W of the motor are respectively connected between the upper and lower arms of the U-phase, V-phase and W-phase of the three-phase inverter, and the system is powered on. The servo controller controls the three-phase inverter V-phase upper arm VH and W-phase lower arm WL to conduct, and the remaining bridge arms UH, UL, VL, and WH are turned off. At this time, the current flows through the V-phase upper arm VH, Motor V-phase winding V, motor W-phase winding W, W-phase lower bridge arm WL, taking the common terminal O of the motor three-phase winding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com