Energy saving reforming system of rectifying tower in production of ethyl acetate

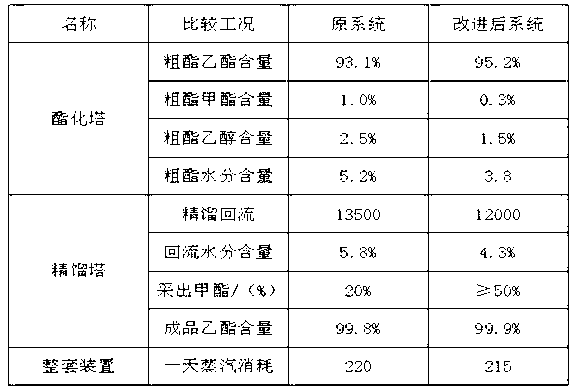

An energy-saving transformation, ethyl acetate technology, applied in the preparation of carboxylate, distillation adjustment/control, fractionation and other directions, can solve the problems of increased energy consumption, low separation rate of methyl acetate, etc. quality, the effect of improving the ethyl ester content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

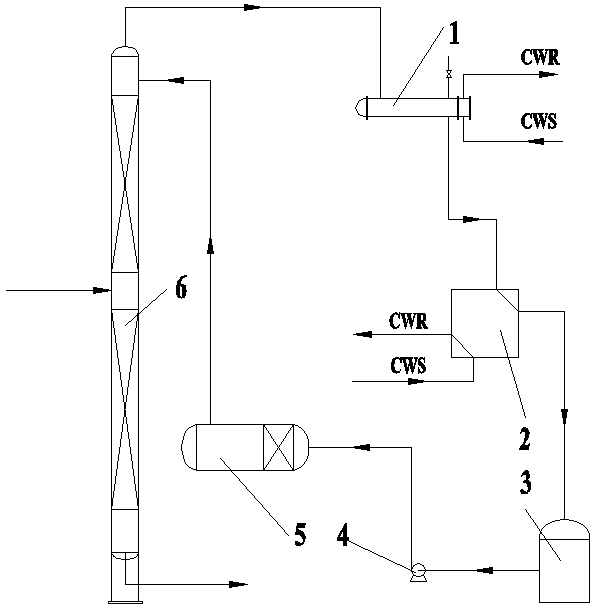

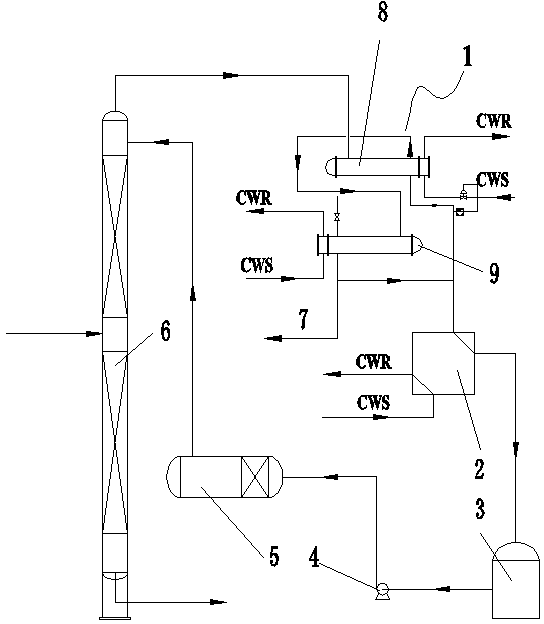

[0022] The specific scheme of this embodiment is: as figure 2 As shown, a rectification tower energy-saving transformation system in the production of ethyl acetate includes a rectification tower 6, and a tower top condenser device 1, a tower top cooler 2, and a condensate are connected in series on the top of the rectification tower in sequence. Collection tank 3, reflux pump 4, tower top phase separator 5, the gaseous phase and the material with methyl ester from the top of the rectification tower pass through the top condenser device, tower top cooler, condensate collection tank, reflux pump and The top phase separator is then returned to the top of the rectification column. The top condenser device is composed of two sequentially connected top condensers. Each top condenser cools the gas phase material through water cooling and controls the temperature of the gas phase material; The tower top condenser is respectively connected with the tower top cooler, and the first tow...

Embodiment 2

[0030] This embodiment 2 is improved on the basis of embodiment 1. Specifically, the two tower top condensers in embodiment 1 are changed into three tower top condensers, and the condensate timing extraction port is set at the third tower top. On the condenser, the rectification tower energy-saving transformation system in the production of ethyl acetate in this embodiment 2 is also a set of 50,000 t / a ethyl acetate rectification tower system.

[0031] The condensing area in the prior art is 160m 2 The single overhead condenser of the tower is replaced by three overhead condensers, and the condensation area of the three overhead condensers is 120 m 2 、40m 2 and 20 m 2 .

[0032]By controlling the amount of circulating condensed water in each overhead condenser, the temperature of the condensate at the outlet of the first overhead condenser is between 68°C and 72°C, and the temperature of the liquid at the outlet of the second overhead condenser is controlled at 65°C to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com