Special machine tool for press mounting of camshaft bush of diesel engine

A special machine tool and camshaft technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low production efficiency and high labor intensity of workers, and achieve the effects of improving production efficiency, reducing processing costs, and reducing cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

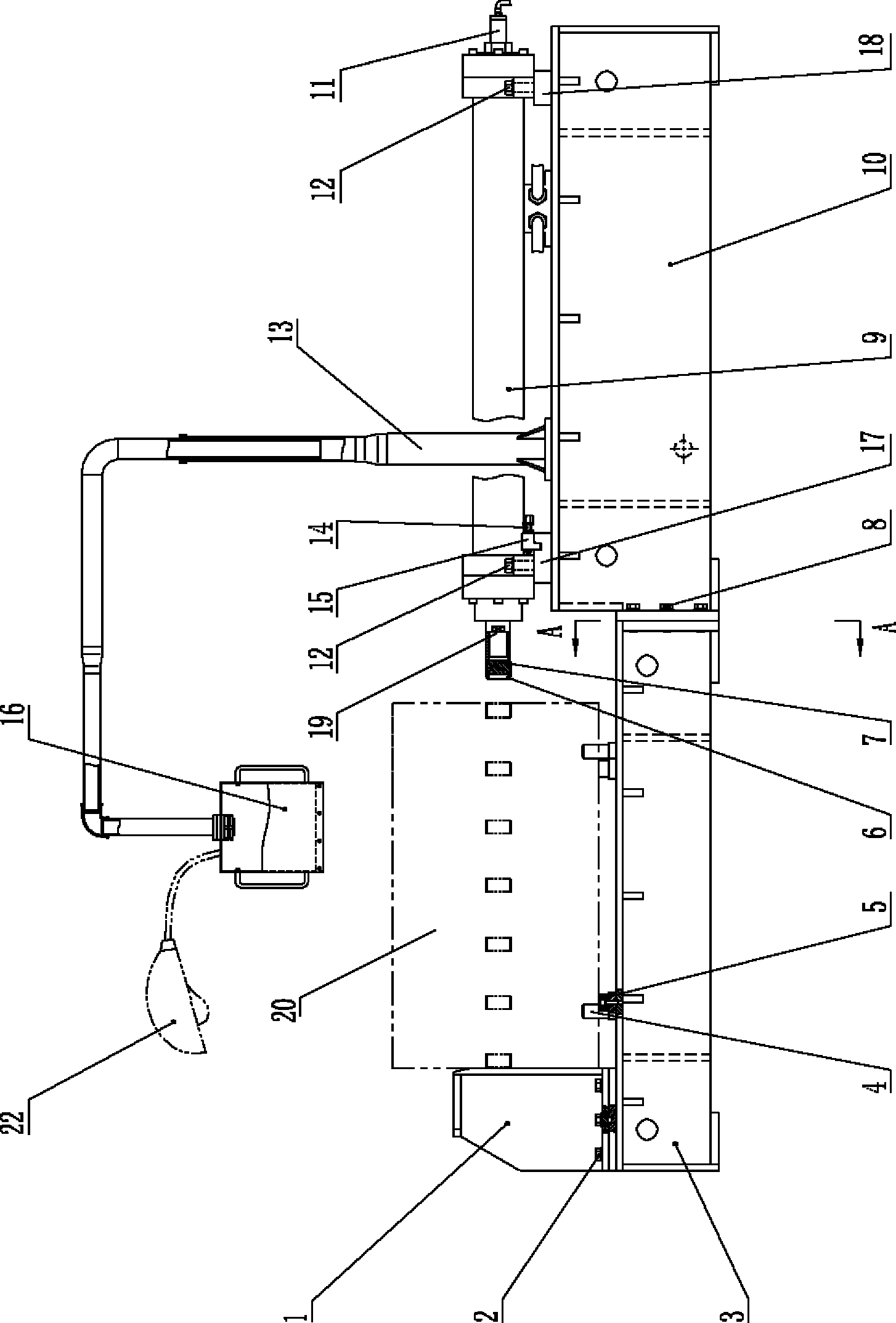

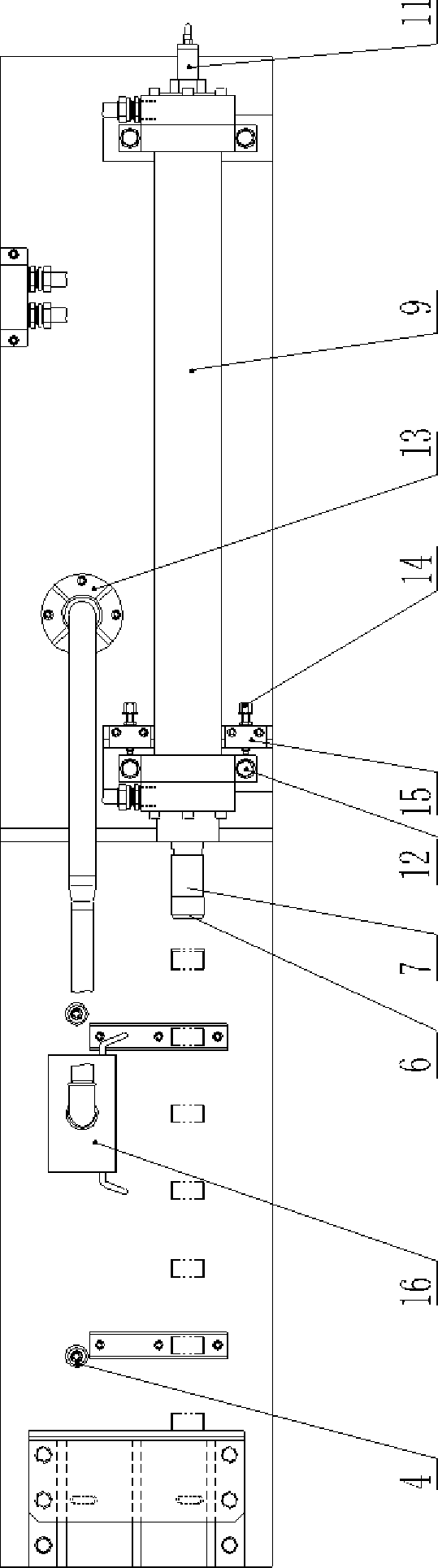

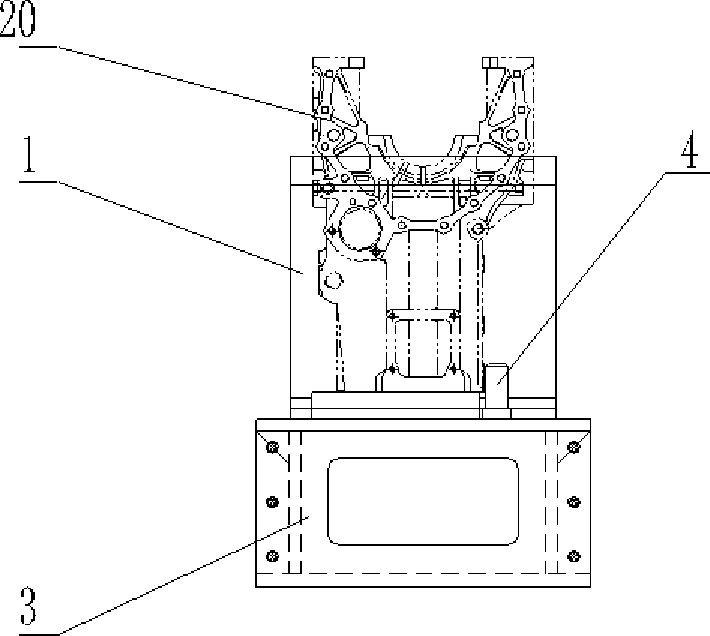

[0012] See figure 1 , figure 2 , image 3 , the present invention is used for the special machine tool for press-fitting of diesel engine camshaft bushings, which includes a front base 3, a rear base 10, a hydraulic cylinder 9 and a control box 16, and the control box 16 and the hydraulic cylinder 9 are electrically connected by PLC. The frame 3 and the rear frame 10 are connected by bolts 8, the front end of the front frame 3 is installed with a tailstock 1 through bolts 2, the front frame 3 is also installed with a limiter 4 and a positioning plate 5, and the hydraulic cylinder 9 passes through the front foot. The seat 17 and the rear foot seat 18 are installed on the rear base 10, the head of the piston rod 19 of the hydraulic cylinder 9 is threadedly mounted with a pressure head 7, the front end of the pressure head 7 is empty with a guide sleeve 6, and the control box 16 is installed on the rear engine through the column 13. on seat 10. The hydraulic cylinder 9 is a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com