Full water stopping side wall template system

A side wall and formwork technology, applied in safety islands, buildings, etc., can solve the problems of high installation density of supporting steel pipes, large joints of bamboo plywood formwork, and low construction efficiency, so as to ensure project quality, improve flatness, and improve Ergonomic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

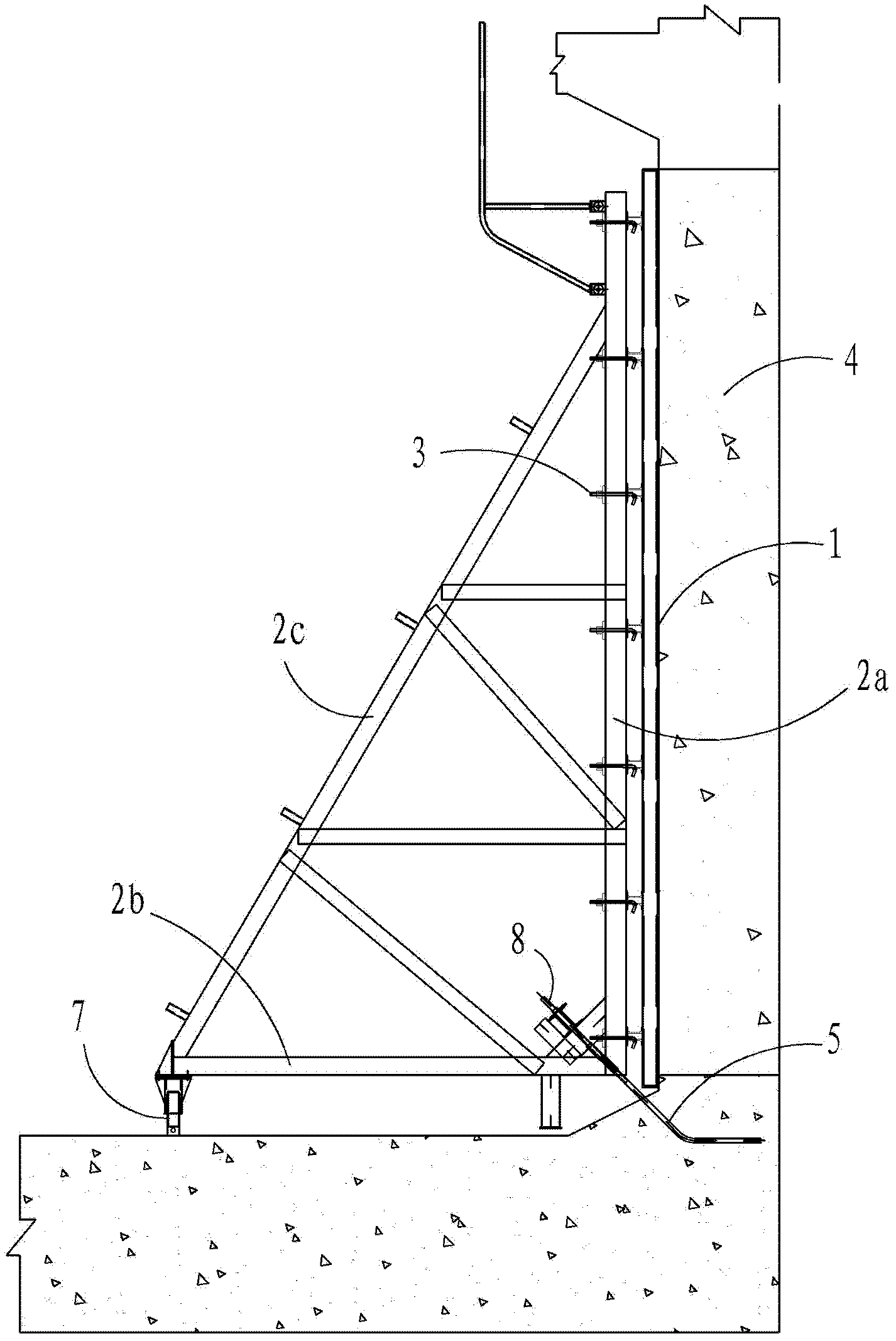

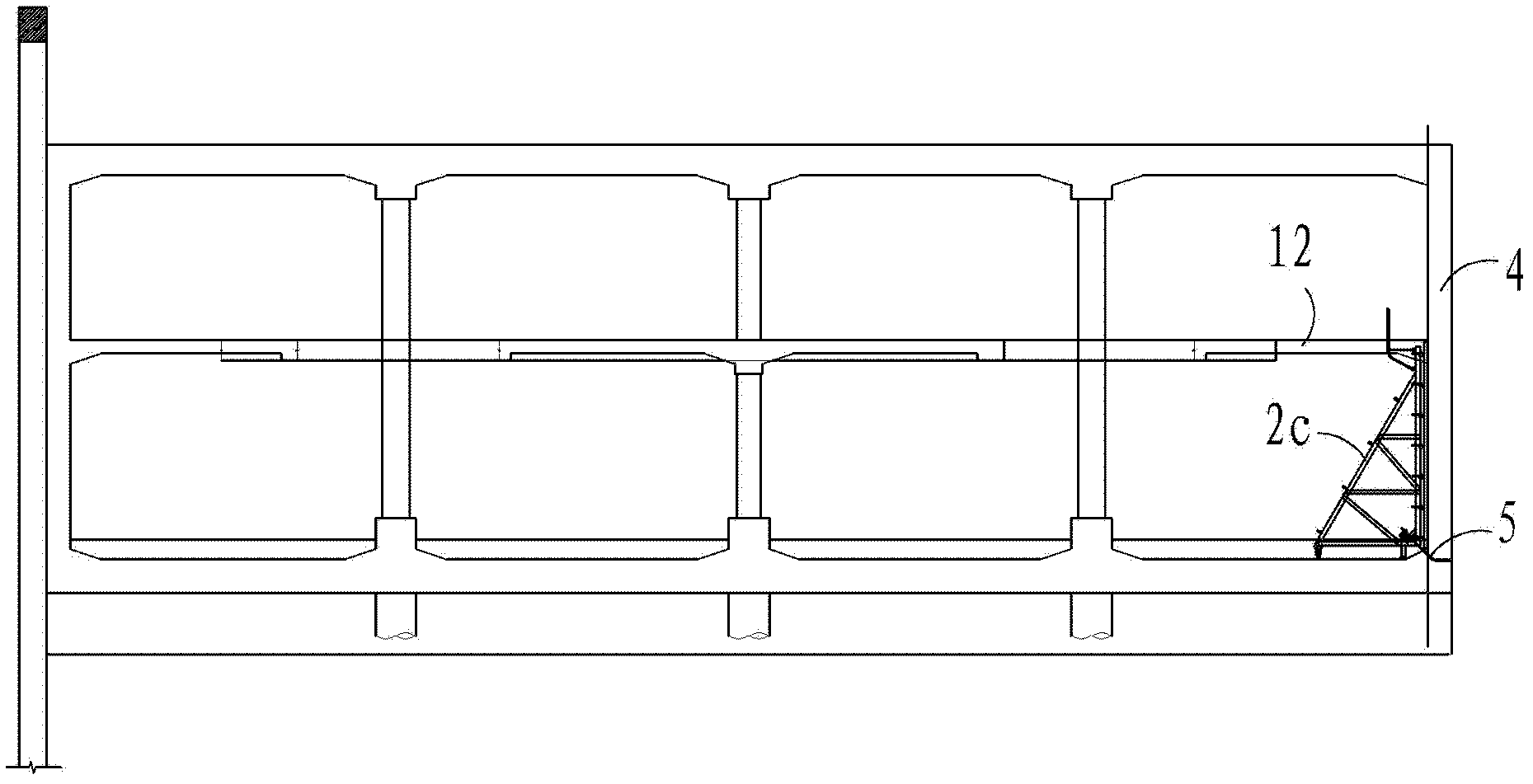

[0022] see figure 1 , figure 2 with image 3 , the structural setting of the full water-stop side wall formwork system in this embodiment is:

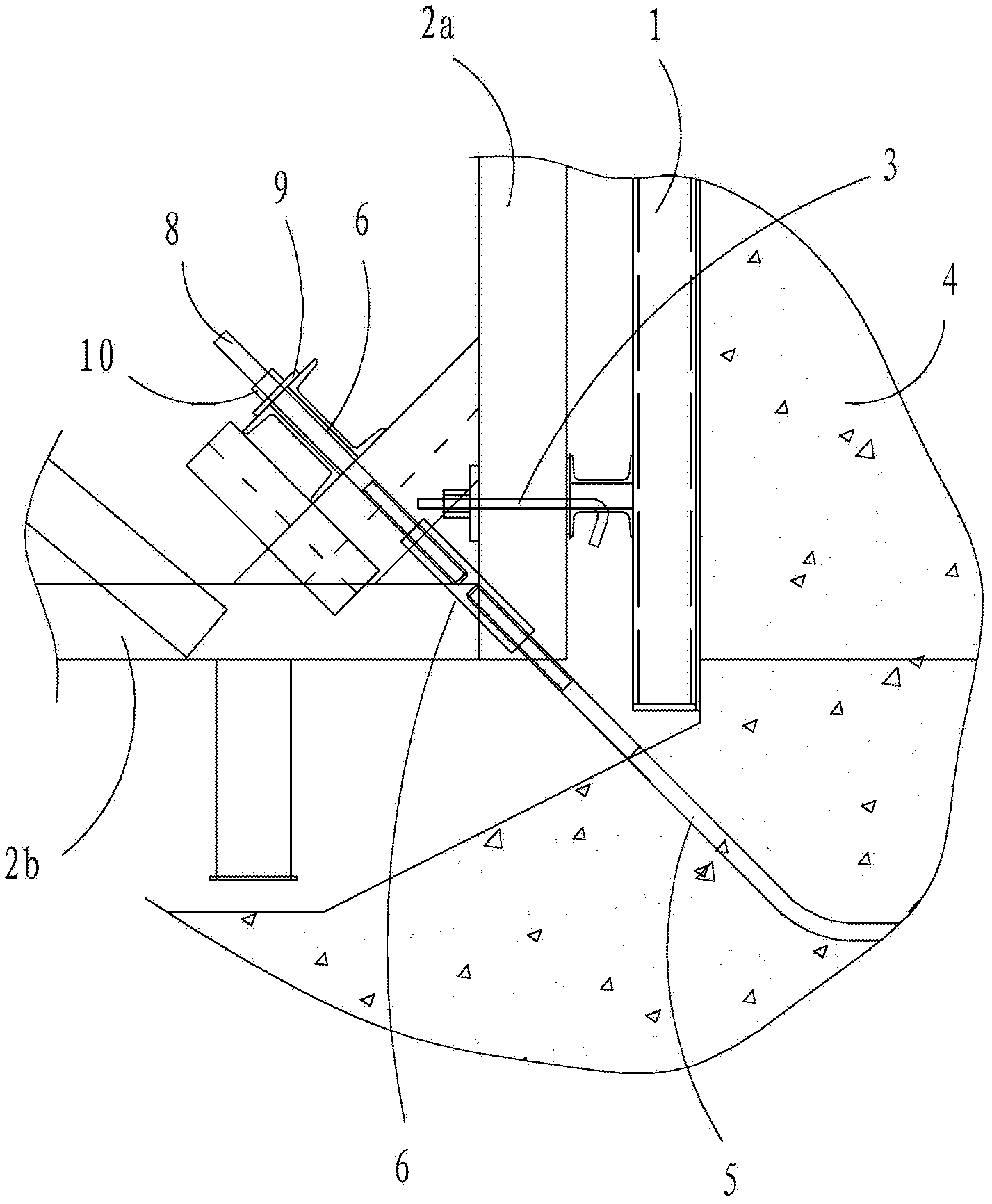

[0023] The side wall formwork 1 adopts a steel formwork, and a triangular bracket composed of a vertical bar 2a, a horizontal bar 2b and a diagonal brace 2c is arranged on the back of the side wall formwork 1, and the triangular support is used to form a triangular support for the side wall formwork 1; The hook bolt 3 is used to connect with the vertical rod 2a of the triangular bracket to form an overall structure; the embedded anchor bolt 5 is set, and the triangular bracket is connected to the embedded bolt 5 of the anchor at the bottom position near the side wall 4 through an external screw rod 8 is anchored with a high-strength nut 10.

[0024] figure 2 As shown, in order to cooperate with the specific installation, the threaded sleeve 6 is used to connect the embedded bolt 5 of the anchor and the external screw rod 8. The e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com