Manufacturing method of terminal electrode of laminated type electronic component

A technology of electronic components and manufacturing methods, which is applied to the manufacture of inductors/transformers/magnets, electrical components, and resistors at the lead-out end, which can solve the problems of long firing and heat preservation time, affecting welding performance, and the bonding force between the silver layer and the porcelain body Poor and other problems, to achieve the effect of little influence on the electrical properties of the product and increase the binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0025] A method for manufacturing a terminal electrode of a laminated chip electronic component, comprising the following steps:

[0026] 1) Make external electrodes

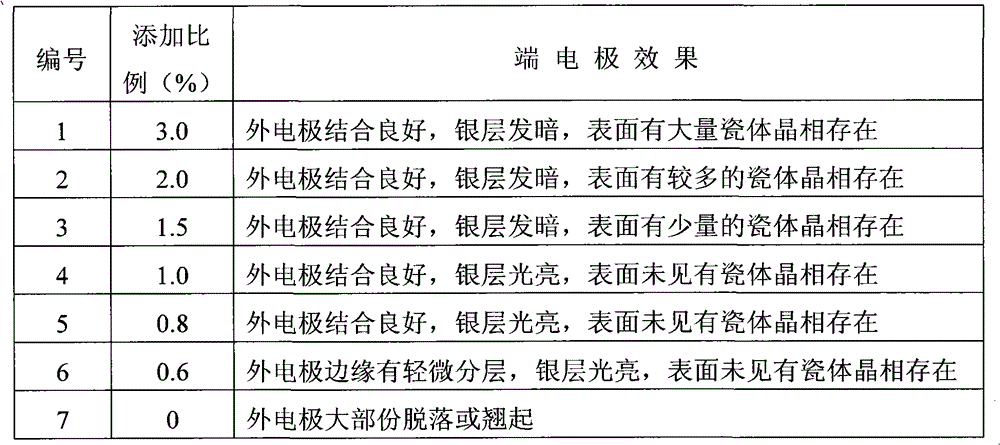

[0027] When the product is laminated and formed, the outer electrode is made by printing on the surface of the product forming body; the printing method is the SP0803 inner electrode silver paste added with L4.6 ceramic powder produced by FERRO company used in the product. Grind the L4.6 ceramic body powder three times with a planetary mill until the average particle size D50 is 0.6 μm; add L4.6 ceramic body powder to the SP0803 inner electrode silver paste and then use a three-roller mill Grind three times to mix the slurry evenly. Table 1 is the external electrode effect of seven different L4.6 ceramic powder additions:

[0028] Table 1

[0029]

[0030] Table 1 shows that the amount of L4.6 porcelain body powder added is 0.6-3.0 (wt)% of the weight of the inner electrode silver paste, and the external e...

specific Embodiment approach 2

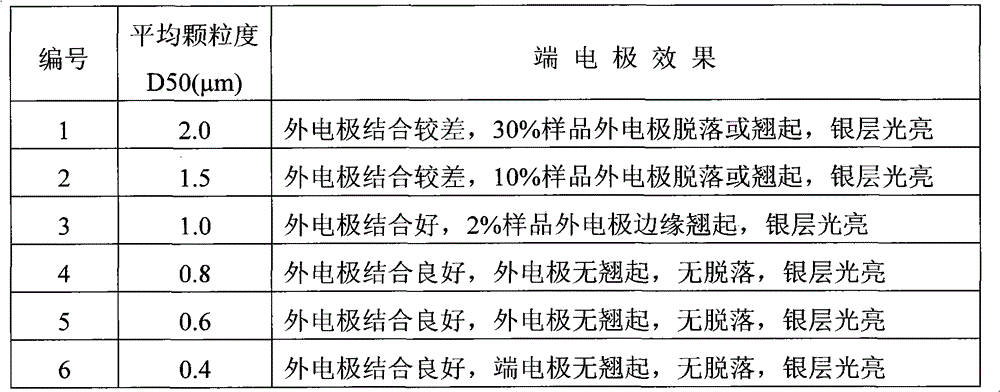

[0041] A method for manufacturing a terminal electrode of a laminated chip electronic component, the steps of which are the same as those of the silver paste and the first embodiment. The amount of L4.6 ceramic body powder added is 0.8 (wt)% of the weight of the silver paste of the inner electrode of SP0803. After the silver paste is added to the porcelain powder, it is rolled three times with a three-roll mill. Table 2 is the external electrode effect of six different L4.6 ceramic powders with an average particle size of D50:

[0042] Table 2

[0043]

[0044] Table 2 shows that the amount of L4.6 porcelain body powder added is 0.8 (wt)% of the silver paste weight of the inner electrode, and the porcelain body powder is a porcelain body powder with an average particle size D50 of 0.4-0.8 μm. The electrode has no warping, no shedding, and the silver layer is bright.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com