Construction method for as-cast finish concrete transparent protective layer

A technology of transparent protective layer and fair-faced concrete, applied in the direction of covering/lining, building, building structure, etc., to achieve the effect of preventing alkali return and increasing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

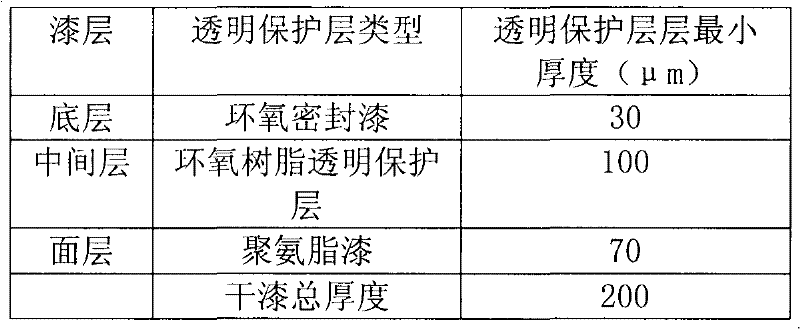

[0011] The method includes concrete surface treatment and concrete transparent protective layer brushing, specifically carried out as follows:

[0012] (1) Concrete surface treatment: For a small number of concrete with large defects or large color differences, clean it with a special cleaning agent, then rinse it with a high-pressure water gun, and use an angle grinder to grind the exposed metal to 0.4-0.5 below the concrete surface mm, paint with anti-rust paint, repair it with flexible putty, and then adjust the color to be basically the same as the large wall with an adjustment material, then polish and putty repair, and properly repair the place where the honeycomb is relatively dense to make it the color Basically consistent with the color of the concrete surface;

[0013] (2) Honeycomb holes with a diameter greater than 4mm and cracks with a width greater than 0.3mm on the surface of concrete beams, slabs, and columns need to be filled and repaired, then chiseled and le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com