Fireplace for vaporizing combustion of liquid fuel

A liquid fuel and fireplace technology, which is applied in the direction of gas fuel burners, liquid heating fuel, liquid fuel supply/distribution, etc., can solve the problems of ineffective control of liquid fuel combustion, insufficient liquid fuel combustion, and low combustion efficiency, etc., to achieve Miniaturized overall structure design, clean fuel combustion, and simplified gasification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment one, such as Figure 1 ~ Figure 4 Shown:

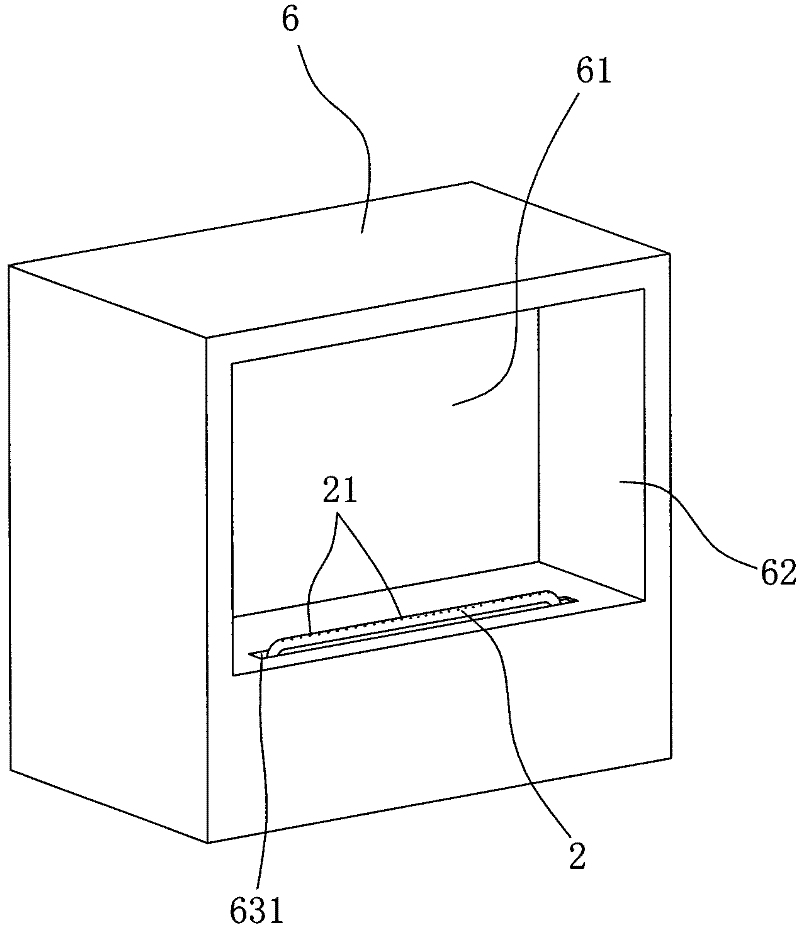

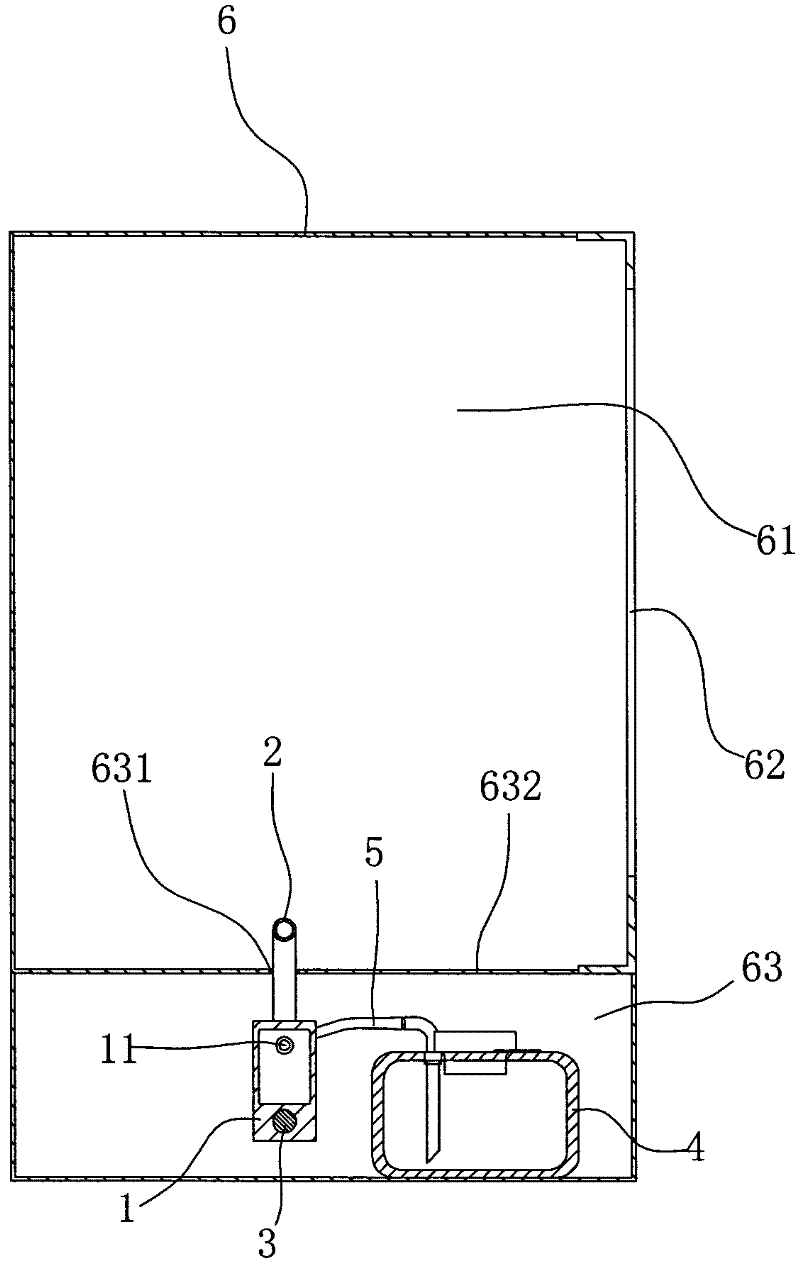

[0025] This embodiment is a fireplace that adopts gasification and combustion of liquid fuel. The fireplace includes a furnace body 6, a furnace chamber 61 is provided inside the furnace body 6, and a flame observation port that communicates with the furnace chamber 61 is also provided at the front of the furnace body 6. 62, and the furnace body 6 also forms a chamber 63 at the bottom of the furnace cavity 62, and a combustion device for gasification and combustion of liquid fuel is placed in the chamber 63;

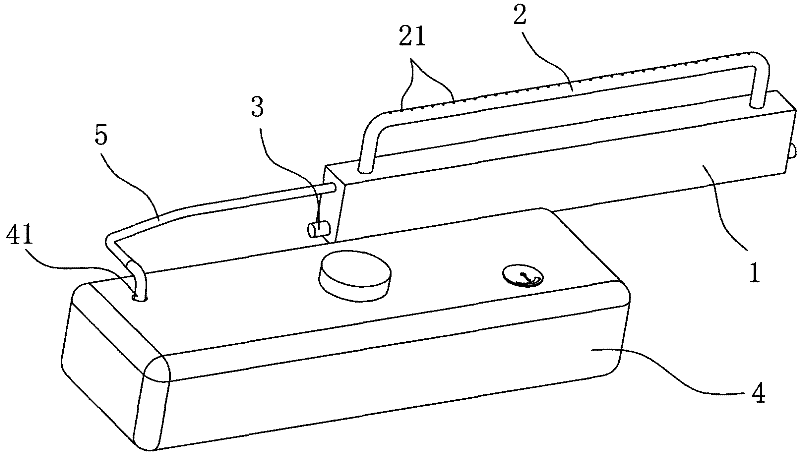

[0026] The combustion device includes a gasification chamber 1, a burner 2, an electric heating device 3, a liquid fuel tank 4 and a feed pipe 5, wherein the top surface 632 of the chamber 63 is provided with a slot 631, and the burner just passes through the slot The hole 631 is exposed in the furnace cavity 61, the side of the gasification chamber 1 is provided with a liquid fuel addition port 11, the side w...

Embodiment 2

[0031] Embodiment two, such as Figure 5 ~ Figure 7 as shown,

[0032] The fireplace in the second embodiment includes a furnace body 9', a furnace cavity 91' is opened inside the furnace body 9', a detachable furnace door 92' is provided on the front of the furnace body 9', and a and The furnace chamber 91' is connected to the flame observation port 921', and the furnace body 9' forms a chamber 93' at the bottom of the furnace chamber 91', and a combustion device for gasification and combustion of liquid fuel is placed in the chamber 93';

[0033] The combustion device of the second embodiment also has a gasification chamber 1', a burner 2', an electric heating device 3', a liquid fuel tank 4' and a feed pipe 5', and between the liquid fuel tank 4' and the gasification chamber 1' Connected by the feed pipe 5', on the feed pipe 5' is also provided with an electromagnetic pump 51' to provide liquid fuel delivery power, the top of the liquid fuel tank 4' is provided with a liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com