Bent non-sensitive micro-structured optical fiber and production method thereof

A microstructure optical fiber, bending-insensitive technology, applied in the directions of cladding optical fiber, optical waveguide light guide, etc., can solve the problem of poor bending loss effect, achieve good optical transmission characteristics and mechanical characteristics, simple and reliable manufacturing method, and overcome the effect. poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

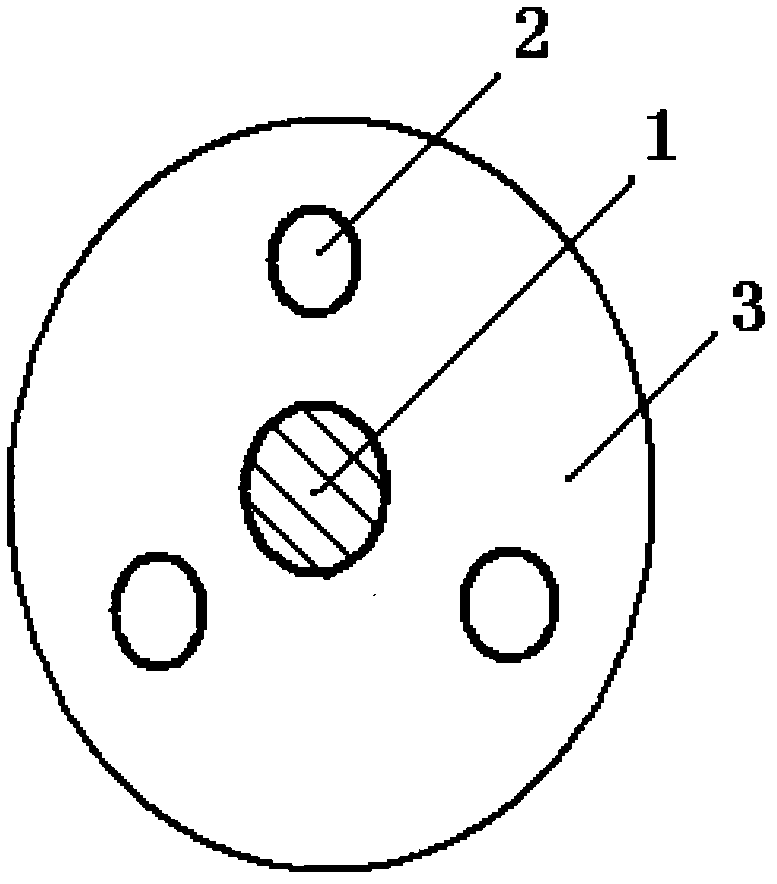

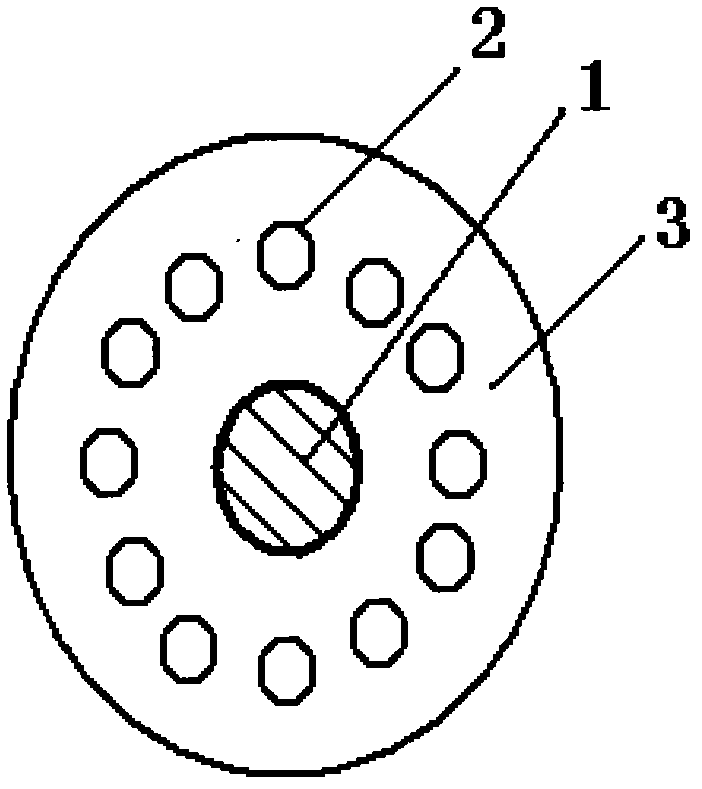

[0061] A target rod with a diameter of 40mm is placed on a VAD deposition lathe, and the mixed gas of silicon tetrachloride, germanium tetrachloride and high-purity oxygen is used to form a germanium-doped quartz glass core layer under the high temperature of the hydrogen-oxygen flame, that is, Figure 4 In the fiber core 1, the total flow rate of the mixed gas is 12000ml / min, and the deposition rate of the core rod is 8g / min to form a germanium-doped core rod. The diameter of the core rod is 30mm, and the diameter of the germanium-doped core layer is 10mm. The relative refractive index difference between the germanium core layer and pure quartz glass is 1.0%.

[0062] see Figure 4 As shown, 12 high-purity quartz tubes 4 with an outer diameter of 10 mm and an inner hole diameter of 7.5 mm are placed along the mandrel (i.e. Figure 4 The fiber cores in 1) are evenly arranged on the outer edge for a week, forming image 3 The 12 air holes 2 in the middle are fixed at the end ...

Embodiment 2

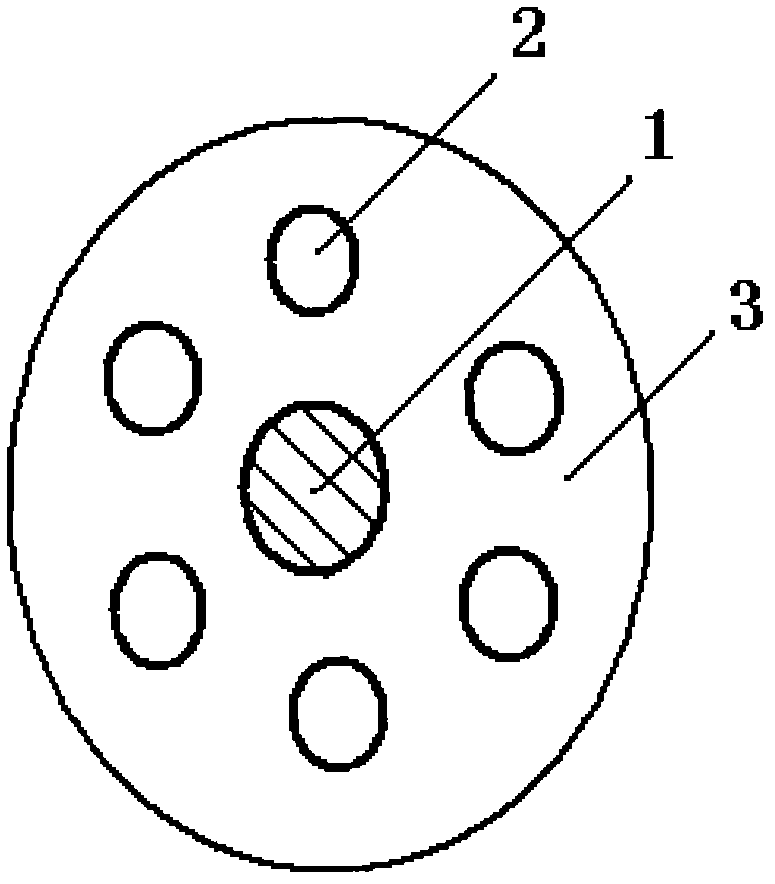

[0068] A pure quartz glass substrate tube with an outer diameter of 35mm and an inner diameter of 31mm is placed on a PCVD deposition lathe, and a mixed gas of silicon tetrachloride, germanium tetrachloride and high-purity oxygen is introduced, and the total flow rate of the mixed gas is 9200ml / min. Under the action of 12.1kW microwave, a germanium-doped quartz core layer is deposited inside the quartz substrate tube. The pressure in the quartz tube is 10.5mbar, and the deposition rate is 4.8g / min. A 5mm thick germanium-doped silicon dioxide core area is deposited, and then On a PCVD rod forming lathe, it melts and shrinks to form a germanium-doped mandrel, forming Figure 4 In the fiber core 1, the diameter of the core rod is 32 mm, the diameter of the germanium-doped core layer is 12.2 mm, and the relative refractive index difference between the germanium-doped core layer and pure silica glass is 0.61%.

[0069] see Figure 4 As shown, 12 high-purity quartz tubes with an ou...

Embodiment 3

[0074] A pure quartz glass substrate tube with an outer diameter of 25mm and an inner diameter of 21mm is placed on an MCVD deposition lathe, and a mixed gas of silicon tetrachloride, germanium tetrachloride and high-purity oxygen is introduced, and the total flow rate of the mixed gas is 10200ml / min. Deposit a germanium-doped quartz core layer inside the quartz substrate tube at a high temperature in an oxygen-hydrogen flame at a deposition rate of 1.8g / min, deposit a germanium-doped silicon dioxide core region with a thickness of 2.5mm, and then melt and shrink to form a germanium-doped core rod. form Figure 4 In the fiber core 1, the diameter of the core rod is 21 mm, the diameter of the germanium-doped core layer is 5 mm, and the relative refractive index difference between the germanium-doped core layer and pure silica glass is 0.25%.

[0075] see Figure 4 As shown, 12 high-purity quartz tubes with an outer diameter of 7 mm and an inner hole diameter of 5 mm are evenly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com