Punch forming machine for electrode plate processing

An electrode sheet and molding machine technology, which is applied in the direction of electrode manufacturing, etc., can solve the problems of being unsuitable for electrode sheet processing, unable to meet the requirements of production automation, high efficiency and low cost, and increasing production costs, so as to improve the electrode sheet punch forming. Processing efficiency, realizing low cost and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

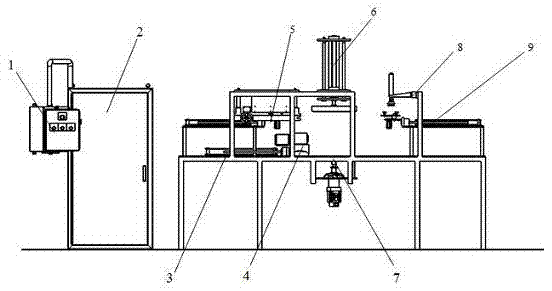

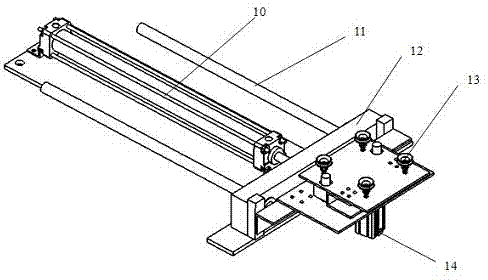

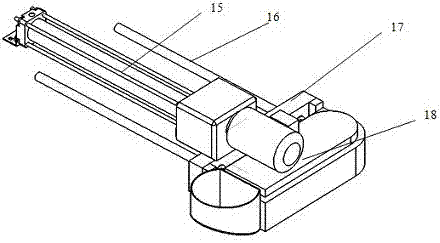

[0041] combine Figure 1~Figure 10 , the fully automatic forming machine capable of processing electrode sheet punches according to the present invention consists of a centralized control system, a frame, a plastic stirring and smearing device, an automatic feeding manipulator, a hot pressing mechanism, a punch forming device, an electrode sending out manipulator, a take-out Electrode manipulator composition. The centralized control system adopts the whole process of industrial PLC control, and the PLC controls the punch processing process of the electrode sheet according to the preset program and the signals sent by each sensor; The guide column, the pushing guide column mounting platform, and the stirring device mounting plate are composed, the stirring device mounting plate is connected with the frame through bolts, the stirring cylinder is connected with the smearing device mounting plate through bolts, The mixer is connected with the pusher cylinder through bolts, the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com