Hydraulic actuator arrangement and a handling arrangement for web rolls and/or reeling shafts of a fiber web machine

A technology of hydraulic actuators and fiber web machines, which is applied in the direction of fluid pressure actuation devices, fluid pressure actuation system components, mechanical equipment, etc., which can solve the problems of pressure reduction and waste, and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

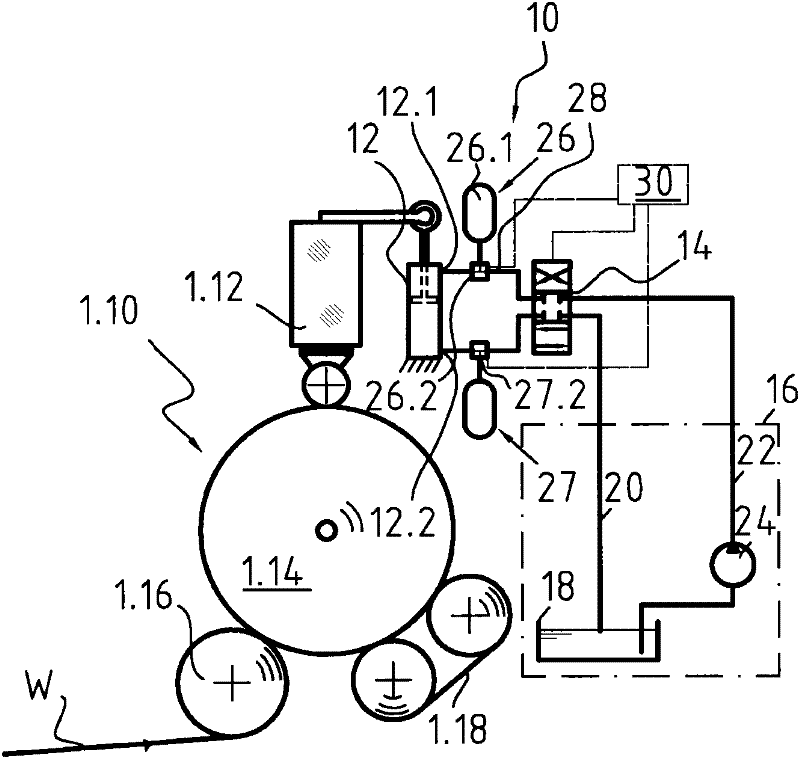

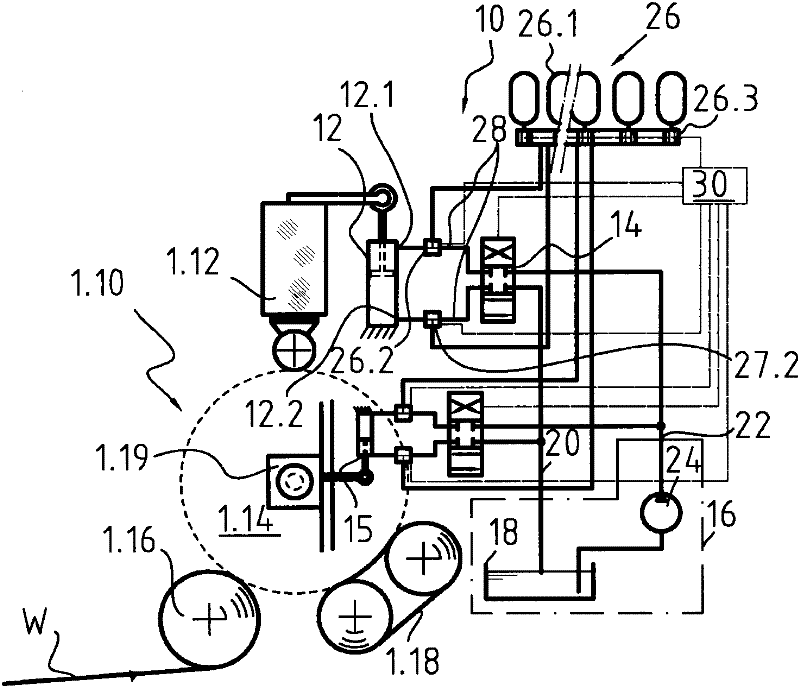

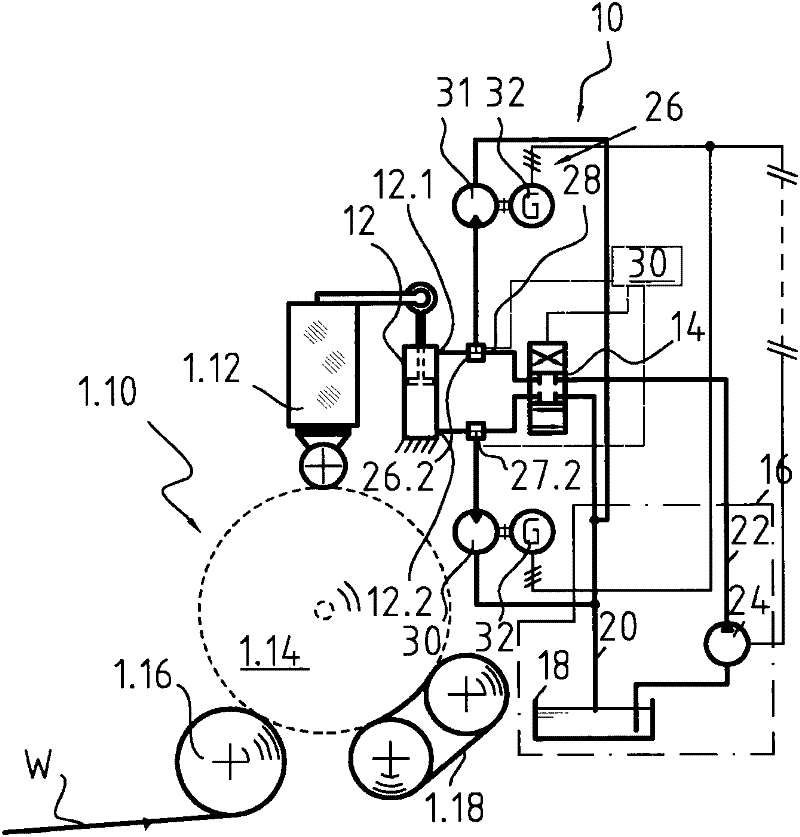

[0033] figure 1 A hydraulic actuator device 10 according to the invention is schematically shown associated with a handling device of a web roll and / or take-up shaft of a fiber web machine. exist figure 1 In the embodiment of , the fiber web machine is the winding section 1.10 of a slitter-winder for winding so-called consumer rolls 1.14. Here, there is a hydraulic actuator device 10 arranged in association with the pinch bar 1.12 of the winding section 1.10, by means of which hydraulic actuator device 10 the coil set to be wound can be supported and / or loaded from one direction. The winding section 1.10 here is a so-called carrier roll winder, and the roll group formed from the partial web W is wound up supported by a carrier roll 1.16 and a belt roll 1.18. Of course, these belt rolls could be another backup roll.

[0034] exist figure 1 In an embodiment of the present invention, the hydraulic actuator device 10 used as the power unit for unloading or loading the coil gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com