Locking mechanism of tank positive-pressure cleaning equipment

A technology of cleaning equipment and locking mechanism, which is applied in the field of airtight car washing equipment for freight tankers, can solve the problems of operator safety impact, high work intensity of workers, and large amount of steam waste, so as to reduce labor intensity, save steam consumption, and increase steam consumption. The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

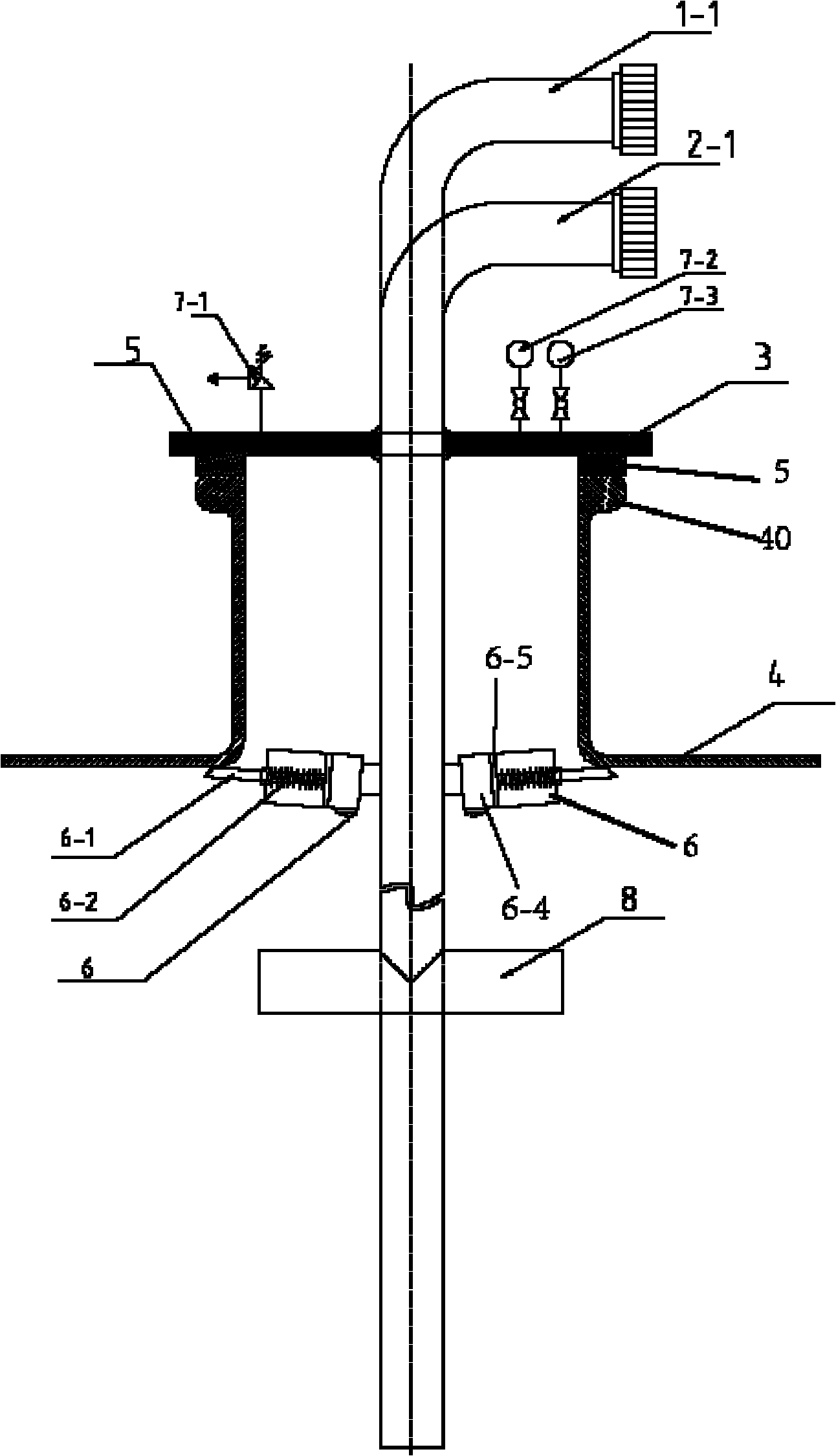

[0027] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0028] see figure 1 , which shows a preferred embodiment of the locking mechanism of a tank positive pressure cleaning device of the present invention, including a compression cover 3 that is fitted and sealed with the tank mouth 40 of the tank, and the compression cover 3 is installed with The steam intake pipe 1-1 and the sewage discharge pipe 2-1 leading to the inside of the tank, the steam intake pipe 1-1 or the sewage discharge pipe 2-1 are also provided with an air valve locking mechanism 6, and the air valve is locked The inner side of the mechanism 6 communicates with the steam inlet pipe 1 - 1 , and the outer side of the gas valve locking mechanism 6 is fit and closed connected with the tank wall 4 of the tank.

[0029] During positive pressure cleaning, the steam pressure pushes the piston plate 6-5 to make ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com