Vibration reduction test device for vibration drilling

A testing device and drill technology, applied in measuring/indicating equipment, drilling/drilling equipment, components of boring machine/drilling machine, etc. Problems such as difficulty in guaranteeing hole processing quality, to achieve the effect of convenient and reliable data processing, improved hole processing quality and efficiency, and less workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

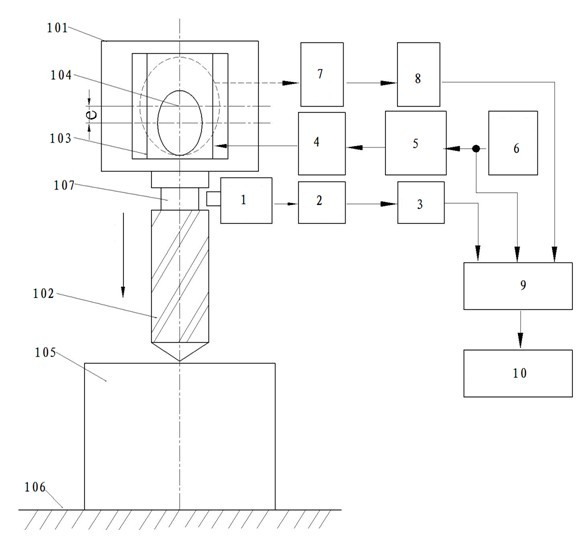

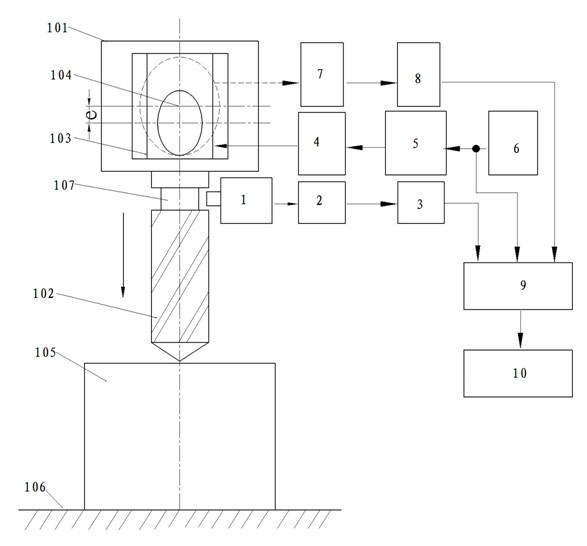

[0010] The drilling vibration reduction test device of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0011] As shown in the figure, the drilling vibration reduction test device of the present invention is connected to the drilling machine 101, including an acceleration sensor 1, a charge amplifier 2, a level meter 3, a DC motor 4, a thyristor DC speed regulating device 5, and a speed command signal generator 6 , Velocimeter 7, Filter 8, Recorder 9 and Spectrum Analyzer 10. A workpiece 105 is mounted on a table 106 of a vertical drilling machine. The drill bit 102 is installed on the main shaft 103 of the drilling machine through the cam mechanism 104 and performs drilling processing on the workpiece 105 .

[0012] The output end of the speed command signal generator 6 is connected to the input end of the thyristor DC speed regulating device 5 , the output end of the thyristor DC speed regulating device 5 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com